Technique for coating layer of power type white light LED plane based on water-soluble sensitization glue

A photosensitive adhesive and power-type technology, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of non-repeatable thickness of phosphor powder, poor uniformity of LED light output, limited yield and industrialized mass production, etc., to improve optical uniformity Sexuality and thermal stability, the effect of improving the overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

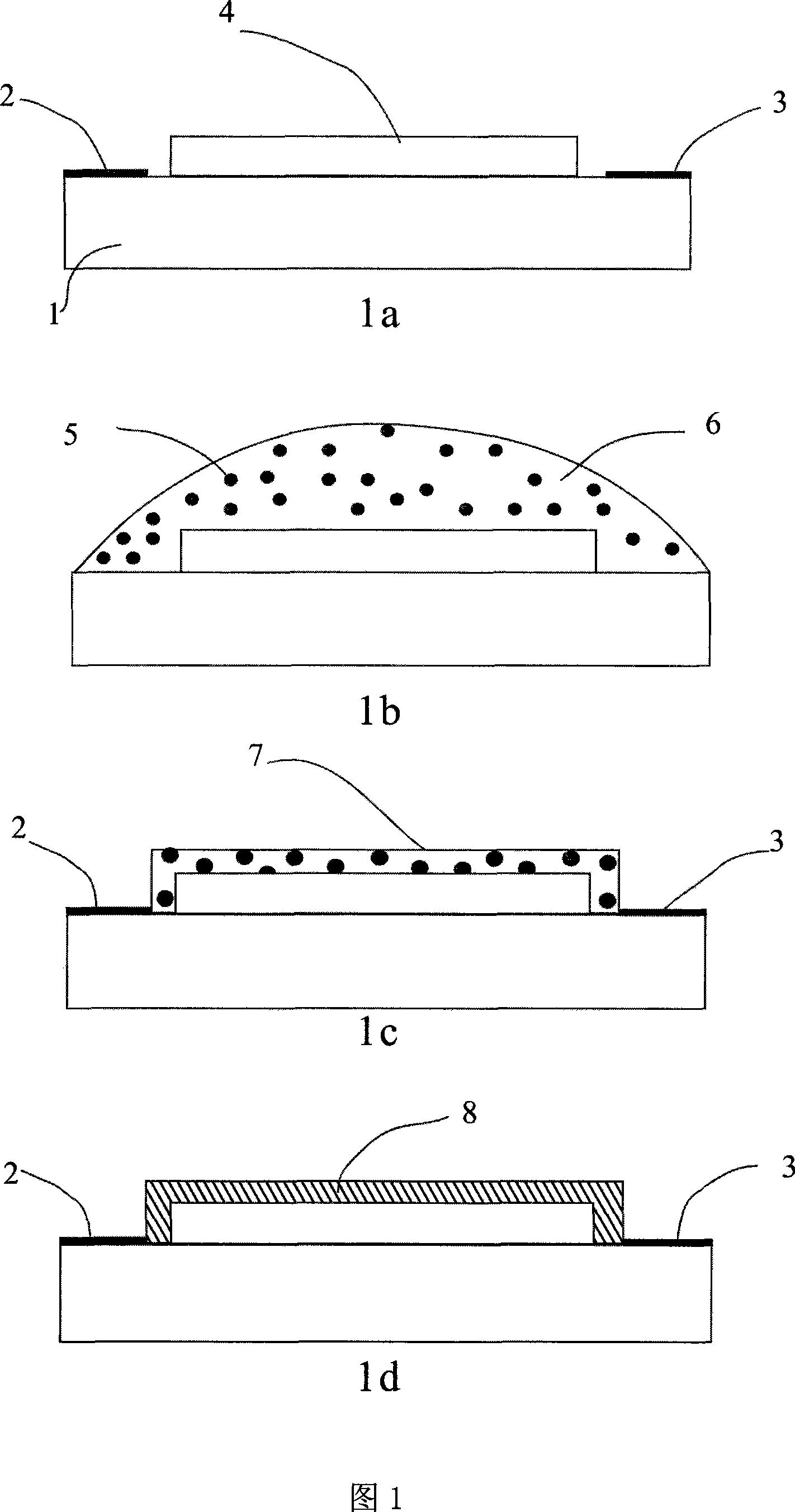

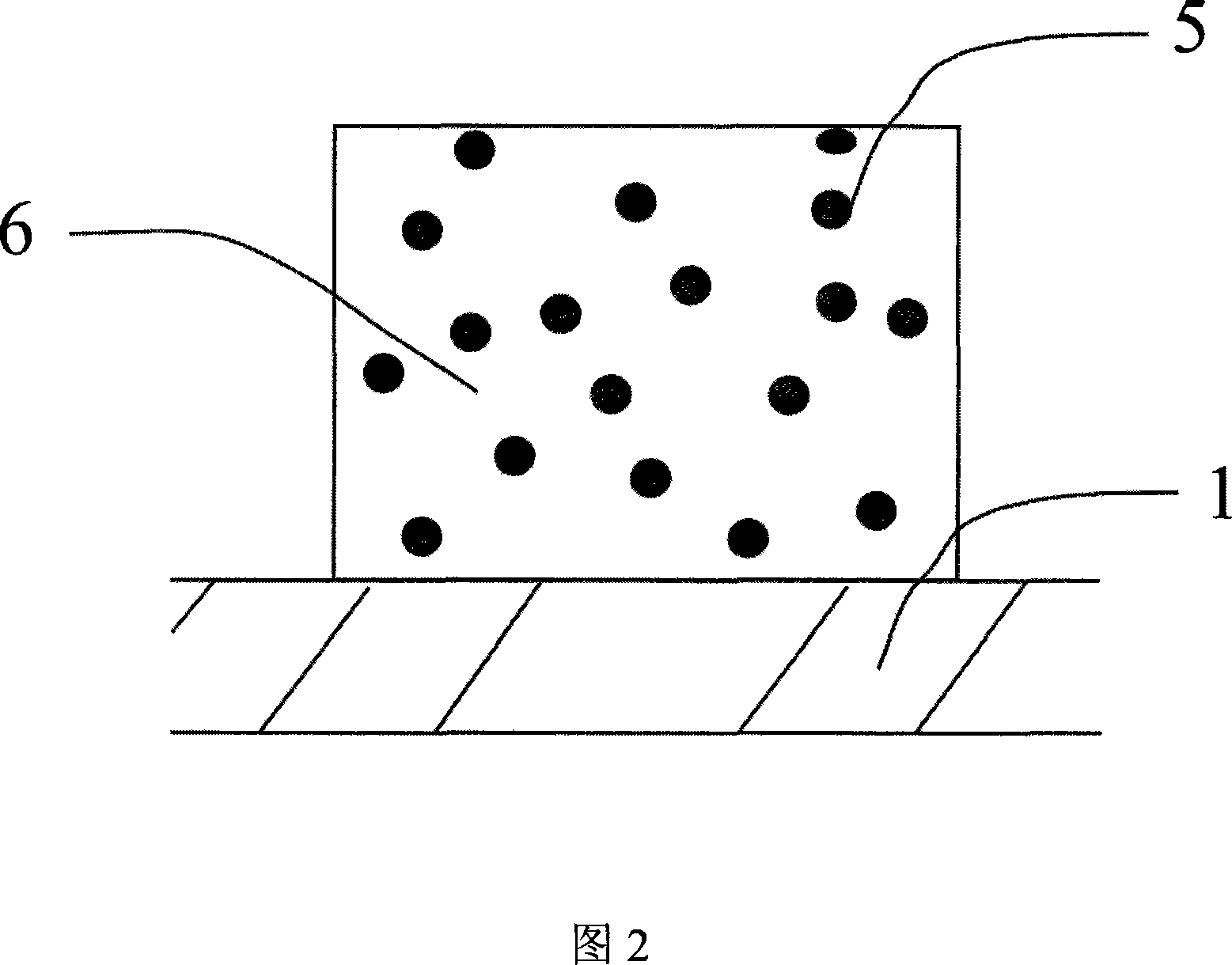

Method used

Image

Examples

Embodiment 1

[0041] Weigh 3.5g of polyvinyl alcohol (PVA) and 43.8mg of sodium dodecylsulfonate mixed with 25ml of deionized water, then add 2.5ml of absolute ethanol and 0.5ml of glacial acetic acid, stir and dissolve in a boiling water bath for about 10min, The solution is transparent and homogeneous, without nodules. Stand still until the bubbles disappear;

[0042] Weigh 315.8mg of ammonium dichromate (ADC) and mix with 6ml of deionized water evenly, and place in a dark room;

[0043] Mix the PVA solution with the ADC solution, add 6ml of silicone defoamer diluted 20 times, stir evenly, and place in a dark room;

[0044] Measure and mix 310ul of silica gel A and silica gel B in equal volume, weigh 800mg of yellow fluorescent powder, mix with the mixed silica gel evenly, and then mix with 3.1ml of the mixed photosensitive adhesive liquid in the previous step to obtain a photosensitive adhesive suspension containing fluorescent powder liquid (i.e. slurry);

[0045] Dispense the photos...

Embodiment 2

[0050] Weigh 3.763g of polyvinyl alcohol (PVA) and mix it with 50ml of deionized water, stir and dissolve in a boiling water bath for about 15min, the solution appears transparent and homogeneous, without nodules. Stand still until the bubbles disappear;

[0051] Weigh 315.8mg of ammonium dichromate (ADC) and mix with 6ml of deionized water evenly, and place in a dark room;

[0052] Mix the PVA solution with the ADC solution, stir evenly, and place it in a dark room;

[0053] Measure and mix 310ul of silica gel A and silica gel B in equal volume, weigh 800mg of yellow fluorescent powder, mix with the mixed silica gel evenly, and then mix with 3.1ml of the mixed photosensitive adhesive liquid in the previous step to obtain a photosensitive adhesive suspension containing fluorescent powder Liquid (ie powder slurry), remove the air bubbles in the powder slurry in a vacuum drying oven;

[0054] Dispense the photosensitive powder paste on the front surface of the chip, coat evenl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com