Pure grain brewing-distilling extracted vinegar

A distillation extraction and pure grain technology, applied in the field of food seasoning, can solve problems such as uncomfortable taste, outdated methods, unhygienic, etc., achieve obvious market development potential, reduce procurement costs, and save transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

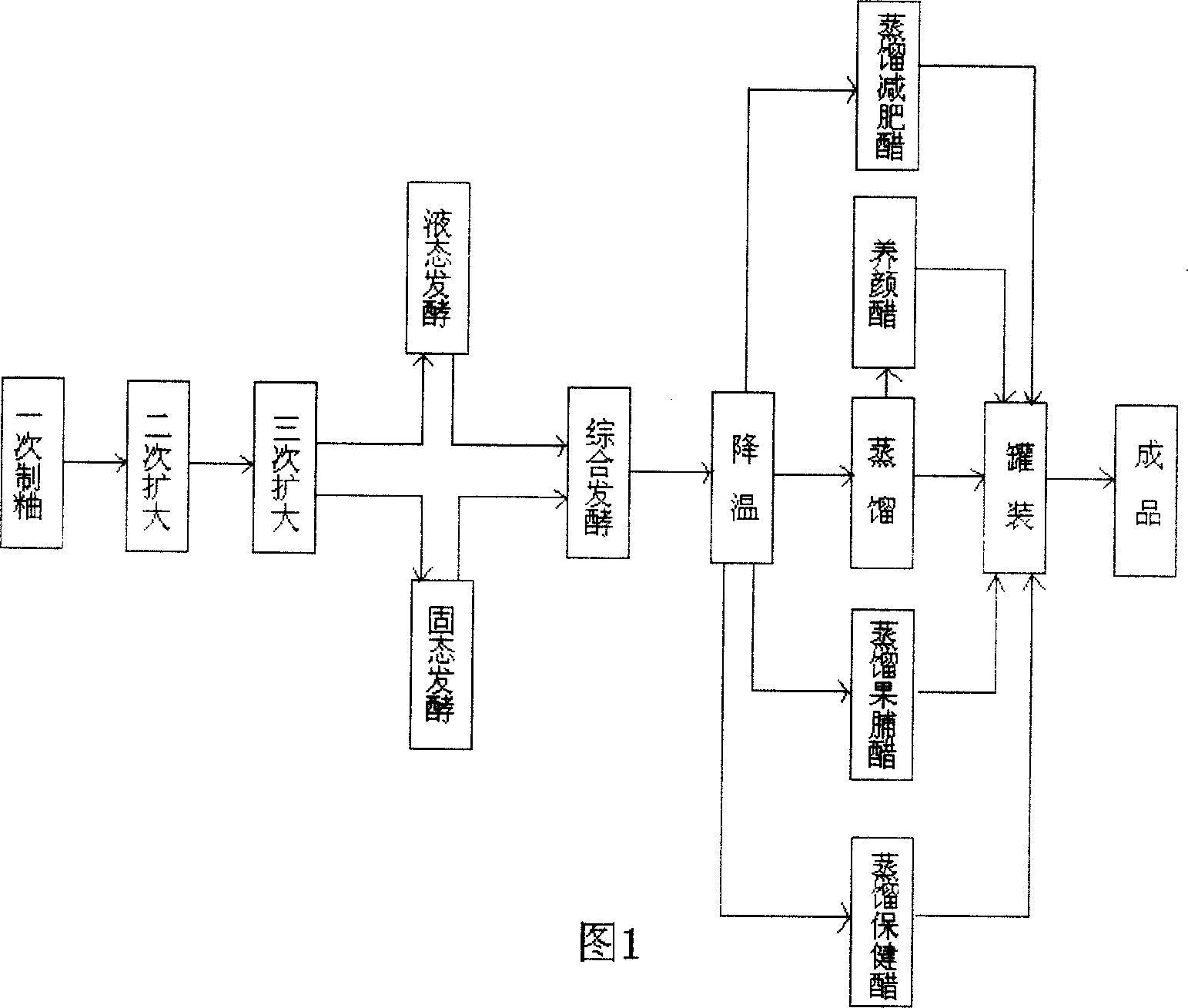

[0035] Embodiment 1 As shown in Figure 1, the raw materials in the following percentages by weight: bran 70%; corn 20%; rice 3%; rice hulls 5%; millet 2%.

[0036] The preparation process of vinegar distilled and extracted with pure grain brewing is as follows:

[0037] The preparation method of the molasses is as follows: take the bacterial strain provided by the Institute of Microbiology of the Chinese Academy of Sciences, the bacterial strain is yeast 2177, and the name is Crebrothecium ashbyii (Crebrothecium ashbyii) for inoculation. This strain can be purchased from the Institute of Microbiology, Xi'an Chinese Academy of Sciences, or it can be sold commercially.

[0038] (1) One-time slant medium: take 6 cc of maltose, 1 gram of peptone, 4 gram of agar, add 200 cc of water, put it into a test tube after melting, it is advisable to fill only one-fifth of each test tube, and carry out autoclaving. The pressure of the bacteria is 103kpa. After sterilization, put it on an in...

Embodiment 2

[0050] Embodiment 2 is composed of raw materials in the following percentages by weight: bran 50%; corn 34%; rice 5%; rice husk 10%; millet 1%.

[0051] The preparation process of vinegar distilled and extracted with pure grain brewing is as follows:

[0052] The preparation method of the molasses is as follows: take the bacterial strain provided by the Institute of Microbiology of the Chinese Academy of Sciences, the bacterial strain is yeast 2177, and the name is Crebrothecium ashbyii (Crebrothecium ashbyii) for inoculation.

[0053] (1) One-time making slant medium: take 6cc of maltose, 1g of peptone, 4g of agar, add 200cc of water, put it into a test tube after melting, and it is advisable to fill only one-fifth of each test tube, and carry out high-pressure sterilization The pressure is 103kpa, put it on a slope after sterilization, inoculate after cooling at 20°C, send it to the greenhouse, keep it warm at 28°C, and cultivate it for 6 days.

[0054] (2), secondary expan...

Embodiment 3

[0064] Example 3 The raw material composition and preparation process of the vinegar extracted by pure grain brewing and distillation are the same as in Example 2, except that step (8) distillation: add: 1% of the vinegar embryo weight percentage in the fermented product vinegar germ Raisins, dried apricots, dried bayberry, the acidity of distilled vinegar is 5 degrees.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com