Preparation of hydroxylamine by one-step method using oxime hydrolysis reaction and infiltration gasification film separation coupling technique

A technology of pervaporation membrane and hydrolysis reaction, applied in the field of preparation of hydroxylamine salt, can solve the problem of conversion rate of only 75%, etc., and achieve the effects of less variety of raw materials, easy operation and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035]A. According to the quantification that the molar ratio of hydrochloric acid to cyclohexanone oxime in the reaction solution is 2, measure 200ml of 2.1mol / L hydrochloric acid solution, weigh 23.73g of cyclohexanone oxime with a purity of 95%, and mix it to prepare into a reaction solution.

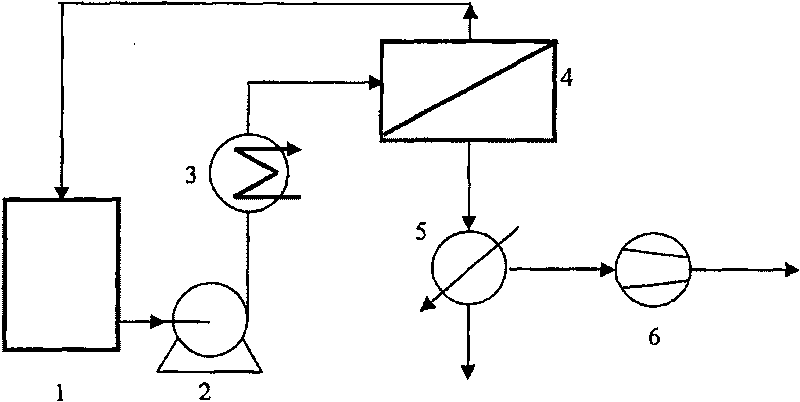

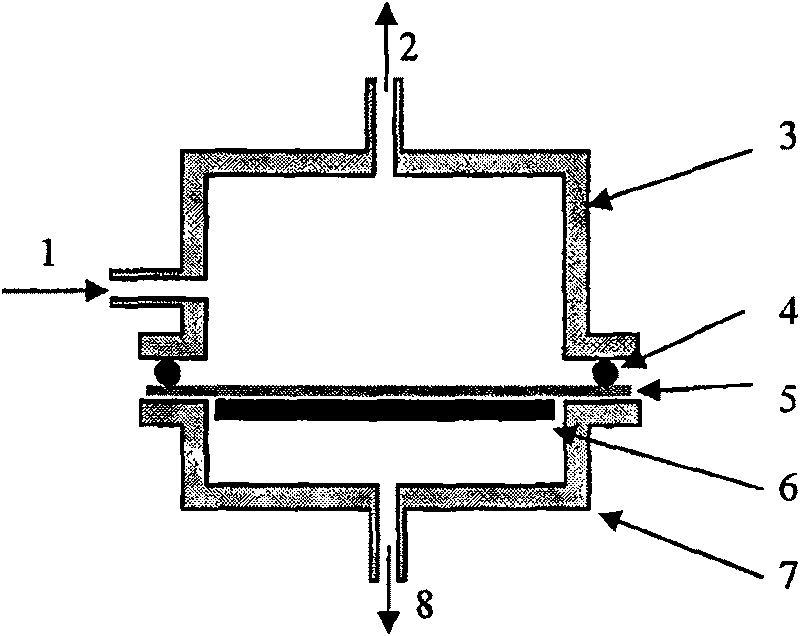

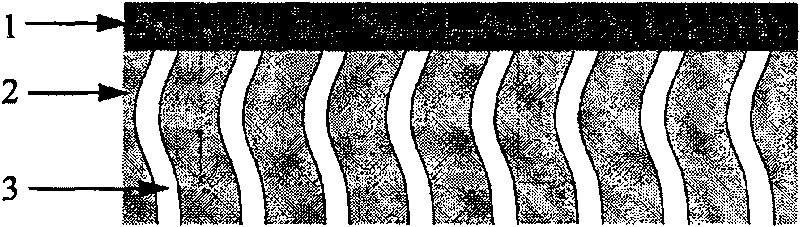

[0036] B. Add the reaction solution to figure 1 In the feed liquid tank of the reaction device coupled with the pervaporation membrane separation process shown. The membrane components used are as figure 2 The flat-plate pervaporation membrane module shown, where the pervaporation membrane is as image 3 As shown in the flat composite membrane, the material of the separation layer is polydimethylsiloxane, and the membrane area is 150.72cm 2 , with a thickness of 20 μm; the support layer is a microporous polytetrafluoroethylene membrane with a thickness of 40 μm and a micropore diameter of 0.2 μm. The reaction temperature was controlled at 50°C.

[0037] C. The reaction solution...

Embodiment 2

[0040] A. According to the quantification that the molar ratio of hydrochloric acid and butanone oxime in the reaction solution is 2, measure 200ml of 2.1mol / L hydrochloric acid solution, weigh 18.27g of butanone oxime with a purity of 99%, and mix it to prepare a reaction solution liquid.

[0041] B. Carry out according to step B among the embodiment 1.

[0042] C. After the reaction was carried out for 2.5 hours, the reaction liquid was collected, and 100 ml of toluene was added thereto according to the volume ratio of toluene to the reaction liquid of 0.5:1, and the oil and water phases were separated to obtain the mother liquor of hydroxylamine hydrochloride.

[0043] The concentration of hydroxylamine hydrochloride was analyzed by titration. Under the same conditions, the equilibrium conversion rate of butanone oxime hydrolysis reaction in hydrochloric acid solution is 23.2%, while using this technology, after the reaction is carried out for 2.5 hours, the reaction conve...

Embodiment 3

[0045] A. According to the quantification that the molar ratio of sulfuric acid and cyclohexanone oxime in the reaction solution is 0.5, measure 200ml of 0.5mol / L sulfuric acid solution, weigh 23.73g of cyclohexanone oxime with a purity of 95%, and mix it to prepare into a reaction solution.

[0046] B. Carry out according to step B among the embodiment 1.

[0047] C. Carry out according to step C among the embodiment 1.

[0048] The concentration of hydroxylamine hydrochloride was analyzed by titration. Under the same conditions, the equilibrium conversion of cyclohexanone oxime hydrolysis reaction in sulfuric acid solution is 4.2%. Using this technology, after the reaction is carried out for 4.5 hours, the conversion rate reaches 66.7%, and the concentration of hydroxylamine hydrochloride in the mother liquor reaches 39.29g / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com