Silicon-phosphor-containing heat-stable hybridized epoxide resin and the preparing method and application thereof

A technology of epoxy resin and phosphorous silicon, which is applied in electrical components, circuits, circuit substrate materials, etc., can solve the problems of the reduction of thermal properties and mechanical properties of epoxy resins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

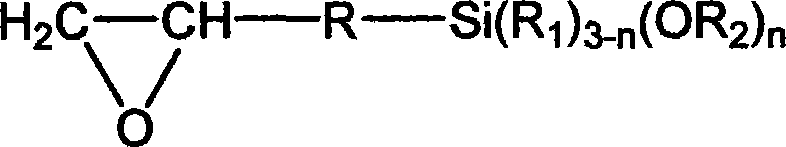

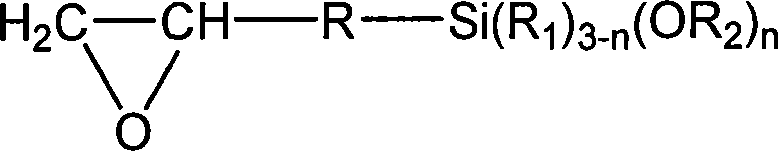

Method used

Image

Examples

Embodiment 1

[0036] With the glycidoxybutyl trimethoxysilane of 100g, 0.2g catalyst dibutyl tin laurate (the consumption of catalyst is 0.2% of the glycidoxybutyl trimethoxysilane quality) and 90g butyl ether solvent Add it into a three-necked flask, add 25g of deionized water dropwise under stirring at 60°C, and drop it in 30 minutes. After reacting at 60°C for 6 hours, a silicon-containing hybrid epoxy resin is obtained, and then add 25.7g of diethyl phosphate , Reflux at 150°C for 5 hours, and cool to remove the solvent butyl ether and the by-product methanol to obtain 94.0 g of phosphorus-containing silicon heat-resistant hybrid epoxy resin with a number average molecular weight of 1779.

[0037] Take 30g of the above-mentioned phosphorus-containing silicon heat-resistant hybrid epoxy resin and compound it with 100g of F51 epoxy resin, and then use 19.4g of triethylenetetramine to cure (the specific process conditions are the same as those in the specification, the same below). The lim...

Embodiment 2

[0039] With the glycidoxypropyl methyldimethoxysilane of 100g, 0.01g catalyst triethylamine (the consumption of catalyst is 0.01% of glycidoxypropylmethyldimethoxysilane quality), 60g toluene and Add 60g of benzene mixed solvent into a three-necked flask, add 40g of deionized water dropwise under stirring at 120°C, and finish adding dropwise in 40 minutes. After reacting at 120°C for 2 hours, a silicon-containing epoxy resin is obtained, and then add DOPO19. 6g, reflux reaction at 100°C for 10h, and cooling to remove the solvent toluene, benzene and by-product methanol to obtain 92.6g of phosphorus-containing silicon heat-resistant hybrid epoxy resin with a number average molecular weight of 954.

[0040] Take 20g of the above-mentioned phosphorus-containing silicon heat-resistant hybrid epoxy resin and compound it with 100g of E51 type epoxy resin, and then use 58.4g of polyamide to cure it. The limiting oxygen index of the cured product is 28.0, the tensile strength is 55MPa...

Embodiment 3

[0042] With the glycidoxypropyl methyl diisopropoxysilane of 100g, 0.001g catalyst hydrochloric acid (the consumption of catalyst is 0.001% of glycidoxypropyl methyl diisopropoxysilane quality) and 50g tetrahydrofuran solvent Add it into a three-necked flask, add 10g of deionized water dropwise under stirring at 50°C, and drop it in 60 minutes. After reacting at 50°C for 8 hours, a silicon-containing epoxy resin is obtained, and then add 10g of phosphoric acid and dimethyl phosphate 16.4 g, reflux at 130°C for 5 hours, and cool to remove the solvent tetrahydrofuran and the by-product isopropanol to obtain 74.1 g of phosphorus-containing silicon heat-resistant hybrid epoxy resin with a number average molecular weight of 569.

[0043] Take 25g of the above-mentioned phosphorus-containing silicon heat-resistant hybrid epoxy resin and compound it with 100g of E44 type epoxy resin, and then use 28.5g of diaminodiphenyl sulfone to cure. The limiting oxygen index of the cured product...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com