Phytate plating resisting agent for heat zinc coating

A technology of phytate and plating flux, which is applied in the direction of hot-dip plating process, coating, metal material coating process, etc., can solve the problems of lack of coverage or insufficient coverage, increase of cost, pollution of the environment, etc., to achieve The effect of low cost, energy saving and high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

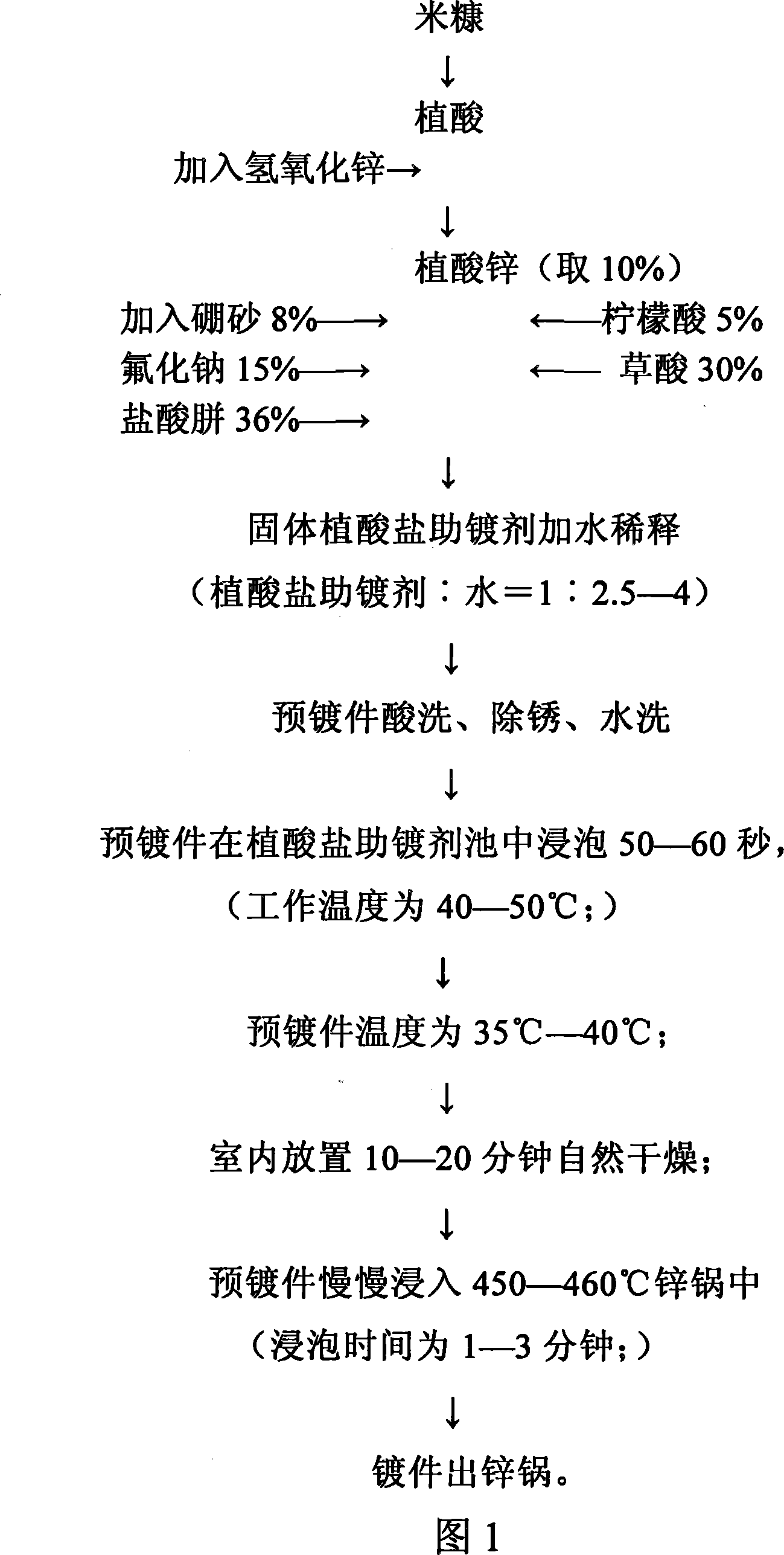

[0016] As shown in Figure 1: the phytate flux for hot-dip galvanizing contains the following components by weight percentage:

[0017] Zinc phytate 10%, using renewable resource rice bran as raw material, phytic acid made by the existing technology reacts with zinc hydroxide to form zinc phytate and then filter and dry, because a certain amount of zinc aluminum alloy is added to the hot-dip galvanizing process , Zinc phytate mainly plays an antioxidant role;

[0018] Borax 4%, acts as a corrosion inhibitor;

[0019] Sodium fluoride 15%, can prevent plating missing plating;

[0020] Citric acid 5%, plays the role of complexing ferrous ions in phytate flux to prevent excessive ferric ions from entering the zinc solution and forming zinc slag;

[0021] 30% oxalic acid, maintain the acidity of the phytate flux, activate the surface of the plating substrate, and increase the adhesion of the plating.

[0022] 36% hydrazine hydrochloride acts to activate the surface of the plating...

Embodiment 2

[0033] The phytate flux for hot-dip galvanizing contains the following components by weight percentage:

[0034] Zinc Phytate 8%, Borax 2%, Sodium Fluoride 13%,

[0035] Citric acid 2%, oxalic acid 35%, hydrazine hydrochloride 40%.

[0036] The hot-dip galvanizing process and advantages using the above phytate flux are the same as in Example 1.

Embodiment 3

[0038] The phytate flux for hot-dip galvanizing contains the following components by weight percentage:

[0039] Zinc Phytate 12%, Borax 6%, Sodium Fluoride 17%,

[0040] Citric acid 7%, oxalic acid 25%, hydrazine hydrochloride 33%.

[0041] The hot-dip galvanizing process and advantages using the above phytate flux are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com