Ginkgo snail-killing micro emulsion and preparation method thereof

A technology of snail microemulsion and ginkgo, which is applied in the field of ginkgo molluscicide microemulsion and its preparation, can solve the problems of poor compatibility and inability to fully reflect the advantages of ginkgo molluscicide, and achieve low cost, easy promotion, use, and production The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

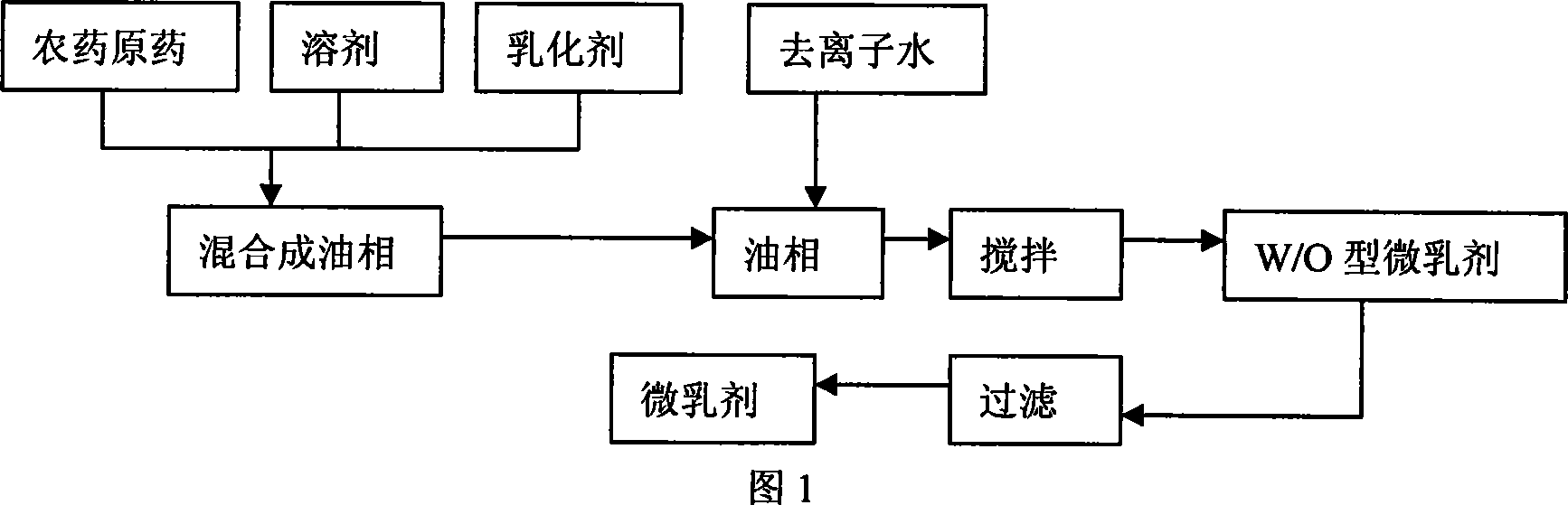

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: the preparation of 2% ginkgo molluscicide microemulsion

[0030] The preparation process of the Ginkgo biloba testa extract containing ginkgolic acid: the Ginkgo biloba testa was dried at 60°C, crushed, passed through a 20-mesh sieve, added petroleum ether (boiling range 60-90°C) and ultrasonically assisted to extract at 30°C. Once, each time for 1 hour, the ratio of the volume and weight of petroleum ether to Ginkgo testa pulverized material is 5: 1 (ml / g); filter under reduced pressure, combine the extracts for 3 times, concentrate under reduced pressure at 60°C, and evaporate Solvent to obtain Ginkgo biloba exocarp petroleum ether extract.

[0031] The preparation process of 2% ginkgolic acid microemulsion: in a 1000 ml there-necked bottle equipped with a stirrer, 20 g of ginkgo exocarp petroleum ether extract, 80 g of absolute ethanol, 80 g of n-butanol, DBS- Ca100g and NP-10100g, after mixing, add 620g deionized water and mix evenly, stir at 50-60°C ...

Embodiment 2

[0032] Embodiment 2: the preparation of 6% ginkgo oncomelania microemulsion

[0033] The preparation process of the Ginkgo biloba testa extract containing ginkgolic acid: the Ginkgo biloba testa was dried at 60°C, crushed, passed through a 20-mesh sieve, and extracted 3 times with ethyl acetate ultrasound at 30°C, 1 hour each time, The volume and weight ratio of ethyl acetate and ginkgo exocarp pulverization is 5:1 (ml / g); filter under reduced pressure, combine 3 extracts, concentrate under reduced pressure at 60°C, and evaporate the solvent to obtain ginkgo exocarp Piper ethyl acetate extract.

[0034] The preparation process of 6% ginkgolic acid microemulsion: in a 1000 ml there-necked bottle equipped with a stirrer, add 60 g of ethyl acetate extract of ginkgo testa, 80 g of absolute ethanol, 80 g of n-butanol, DBS successively under high-speed stirring - Ca100g and NP-10100g, after mixing, add 580g deionized water and mix evenly, stir at 50-60°C at high speed until it beco...

Embodiment 3

[0035] Embodiment 3: the preparation of 10% ginkgo oncomelania microemulsion

[0036] The preparation process of the Ginkgo biloba testa extract containing ginkgolic acid: the Ginkgo biloba testa was dried at 60°C, crushed, passed through a 20-mesh sieve, extracted 3 times with ethanol ultrasound at 30°C, and the ethanol and Ginkgo biloba testa were crushed The ratio of volume to weight of the product is 5:1 (ml / g); filter under reduced pressure, combine 3 extracts, concentrate under reduced pressure at 60°C, and evaporate the solvent to obtain ethanol extract of Ginkgo biloba exocarp.

[0037] The preparation process of 10% ginkgolic acid microemulsion: In a 1000 ml there-necked bottle equipped with a stirrer, add 100 g of ginkgo exocarp ethanol extract, 80 g of absolute ethanol, 80 g of n-butanol, and 100 g of DBS-Ca successively under high-speed stirring and 100g of NP-10, after mixing, add 540g of deionized water and mix evenly, stir at 50-60°C at high speed until it becom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com