Continuous surface micro-structure forming method based on microlens array

A micro-lens array and micro-structure forming technology, which is applied in micro-structure technology, micro-structure devices, manufacturing micro-structure devices, etc., can solve the problems of difficulty in making small-scale graphics and complicated processes, and achieve simple continuous surface structure forming technology Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with specific embodiments, but the scope of protection of the present invention is not limited to the following examples, and should include all content in the claims.

[0029] The mask pattern in the present invention is a periodic pattern, or is a non-periodic pattern, and the base material selection infrared material and visible light material also all have the same process steps, etc., so the present invention only provides an embodiment, and other implementation modes are the same as this implementation The examples are completely similar.

[0030] Concrete implementation steps of the present invention are as follows:

[0031] (1) Coating photoresist S1805 on the surface of the quartz substrate.

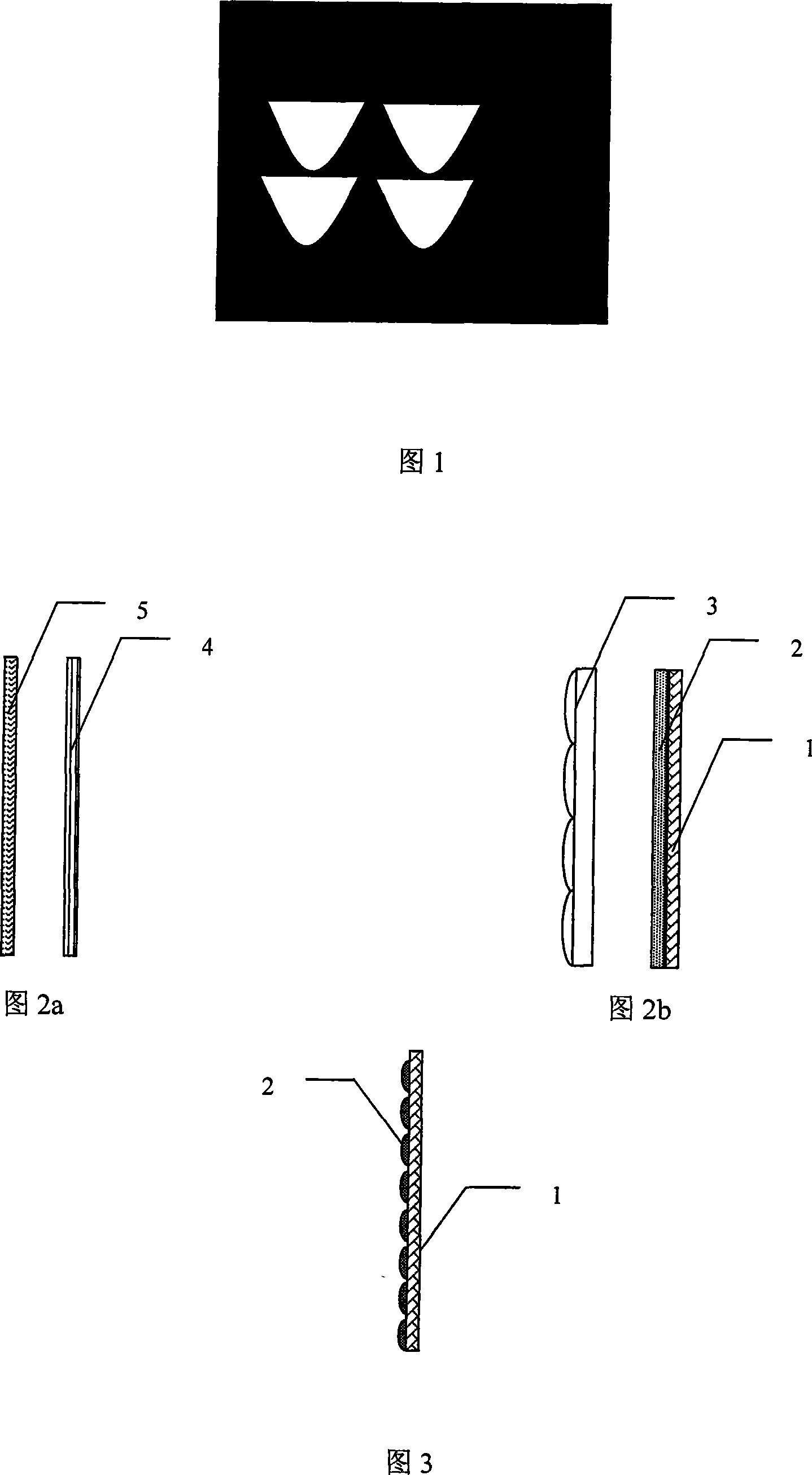

[0032] (2) Place the S1805 photoresist surface of the substrate and the mask pattern on the image plane and object plane of the microlens array respectively. The mask pattern is shown in Figure 1. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com