Method for improving Y-shaped molecular sieve water heat stability by employing cage heteroatom

A technology of hydrothermal stability and thermal stability, applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of low crystallinity and hydrothermal stability, and the reaction process that cannot be applied to catalytic cracking, etc. problems, to achieve the effect of improving skeleton stability, improving thermal stability and hydrothermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

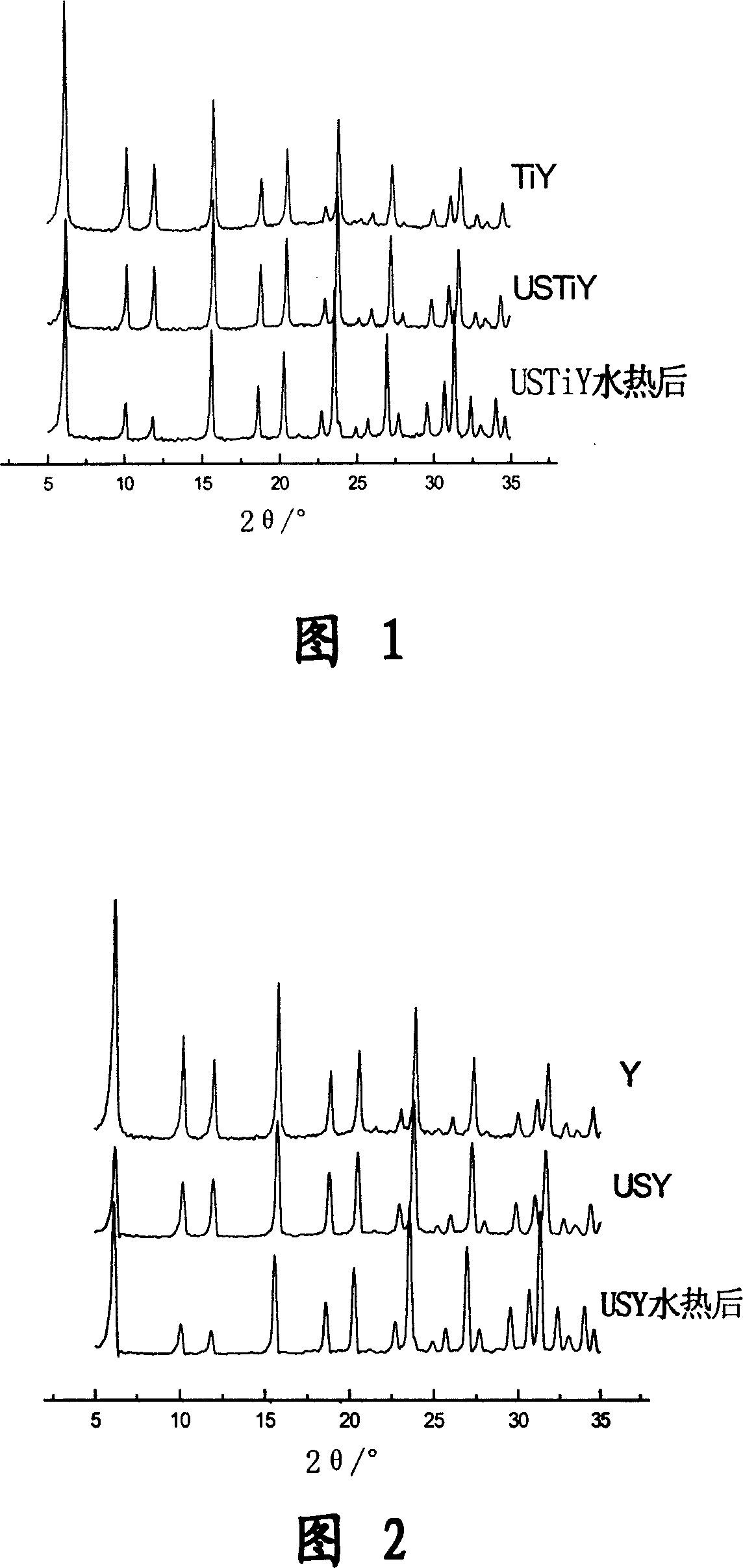

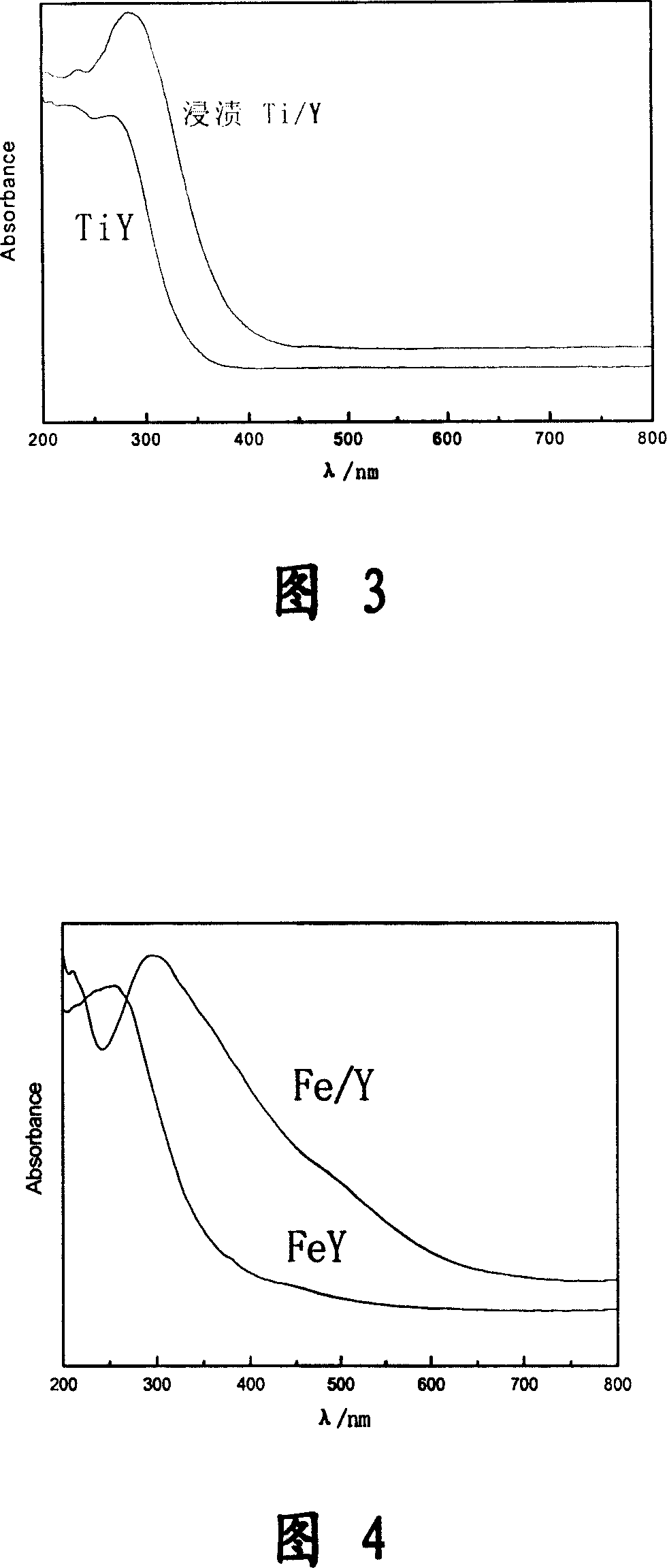

[0030] Example 1: Preparation and ultra-stable treatment of TiY molecular sieve

[0031] Step 1: Preparation of crystallization directing agent

[0032] According to 15Na 2 O: Al 2 o 3 : 2Ti(SO 4 ) 2: 15SiO 2 : 230H 2 The ratio of O is water glass (Beijing Red Star Soda Soda Factory, modulus: 3.1~3.4), NaOH (Beijing Chemical Plant, chemically pure, effective content ≮82%), NaAlO 2 (Beijing Chemical Plant, chemically pure), Ti(SO 4 ) 2 (Beijing Chemical Plant, chemically pure) and H 2 After mixing O evenly, age at 30°C for 3 days to obtain the liquid phase directing agent.

[0033] Step 2: Synthesis of TiY molecular sieve

[0034] According to 3.5Na 2 O: Al 2 o 3 : Ti(SO 4 ) 2 : 9SiO 2 : 320H 2 The raw material ratio of O is water glass (same as above), NaOH (same as above), aluminum sulfate (Beijing chemical plant, chemically pure), Ti (SO 4 ) 2 (Beijing chemical plant, chemically pure), directing agent (the amount of directing agent added is Al in the reac...

Embodiment 2

[0041] Example 2: Preparation and ultra-stable treatment of the comparative sample Y molecular sieve

[0042] Step 1: Preparation of crystallization directing agent

[0043] According to 15Na 2 O: Al 2 o 3 : 15SiO 2 : 230H 2 The ratio of O is water glass (Beijing Red Star Soda Soda Factory, modulus: 3.1~3.4), NaOH (Beijing Chemical Plant, chemically pure, effective content ≮82%), NaAlO 2 (Beijing Chemical Plant, chemically pure) and H 2 After mixing O evenly, age at 30°C for 3 days to obtain the liquid phase directing agent.

[0044] Step 2: Synthesis of Y molecular sieve

[0045] According to 3.5Na 2 O: Al 2 o 3 : 9SiO 2 : 320H 2 The raw material proportioning of O, with water glass (same as above), NaOH (same as above), aluminum sulfate (Beijing chemical plant, chemically pure), directing agent (directing agent add-on is Al in the reaction system 2 o 3 10% of the total substance mass) and H 2 O mixed evenly to obtain an opaque milky white gel. The obtained gel...

Embodiment 3

[0052] Embodiment 3: Preparation and ultra-stable treatment of FeY molecular sieve

[0053] Step 1: Preparation of crystallization directing agent

[0054] With embodiment 1 step one, the heteroatom source Ti(SO 4 ) 2 Replaced by Fe(NO 3 ) 3 .

[0055] Step 2: Synthesis of FeY molecular sieve

[0056] With embodiment 1 step 2, the heteroatom source Ti(SO 4 ) 2 Replaced by Fe(NO 3 ) 3 , the content of Fe atoms in the crystallized product is 4.2wt%, and the Na in the crystallized product is analyzed by X-ray fluorescence detection. 2 O content is 15.2wt%, Al 2 o 3 Content is 22.9wt%, SiO 2 The content is 57.6wt%, Fe 2 o 3 The content is 4.3wt%, and the crystallinity of the FeY molecular sieve is 80% as detected by XRD.

[0057] Step 3: Ultra-stable treatment of FeY molecular sieve

[0058] With step 3 of embodiment 1, the heteroatom Y molecular sieve USFeY1 and USFeY2 of ultra-stable treatment are obtained through bis-cross-baking, wherein USFeY1 adds a small amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com