Method for preparing three hetero arms asteroid polymer

A technology of star structure and polymer, which is applied in the field of preparation of three heteroarm star structure polymers, can solve problems such as difficulties and achieve good controllability and strong universal significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

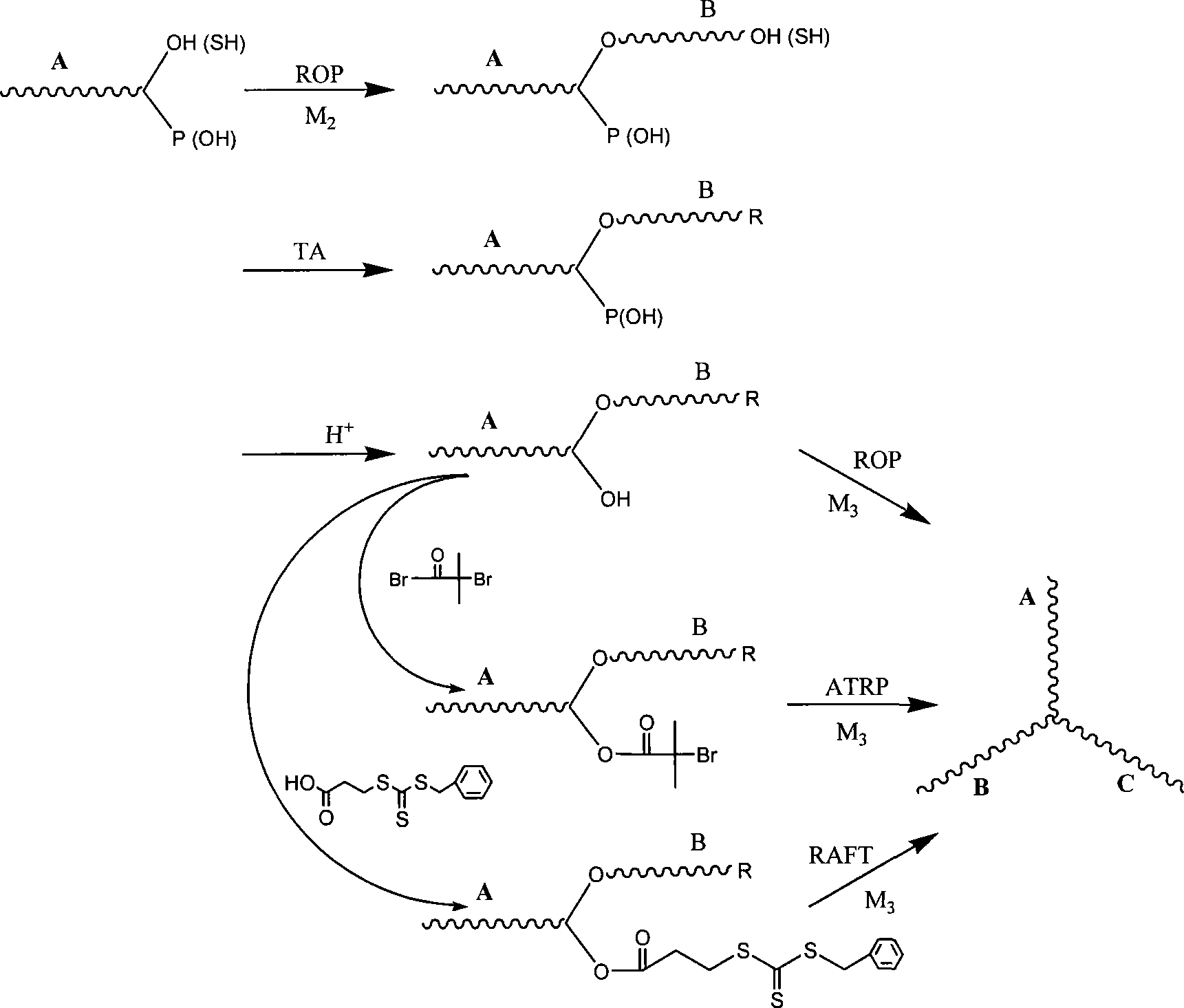

Method used

Image

Examples

Embodiment 1

[0031]

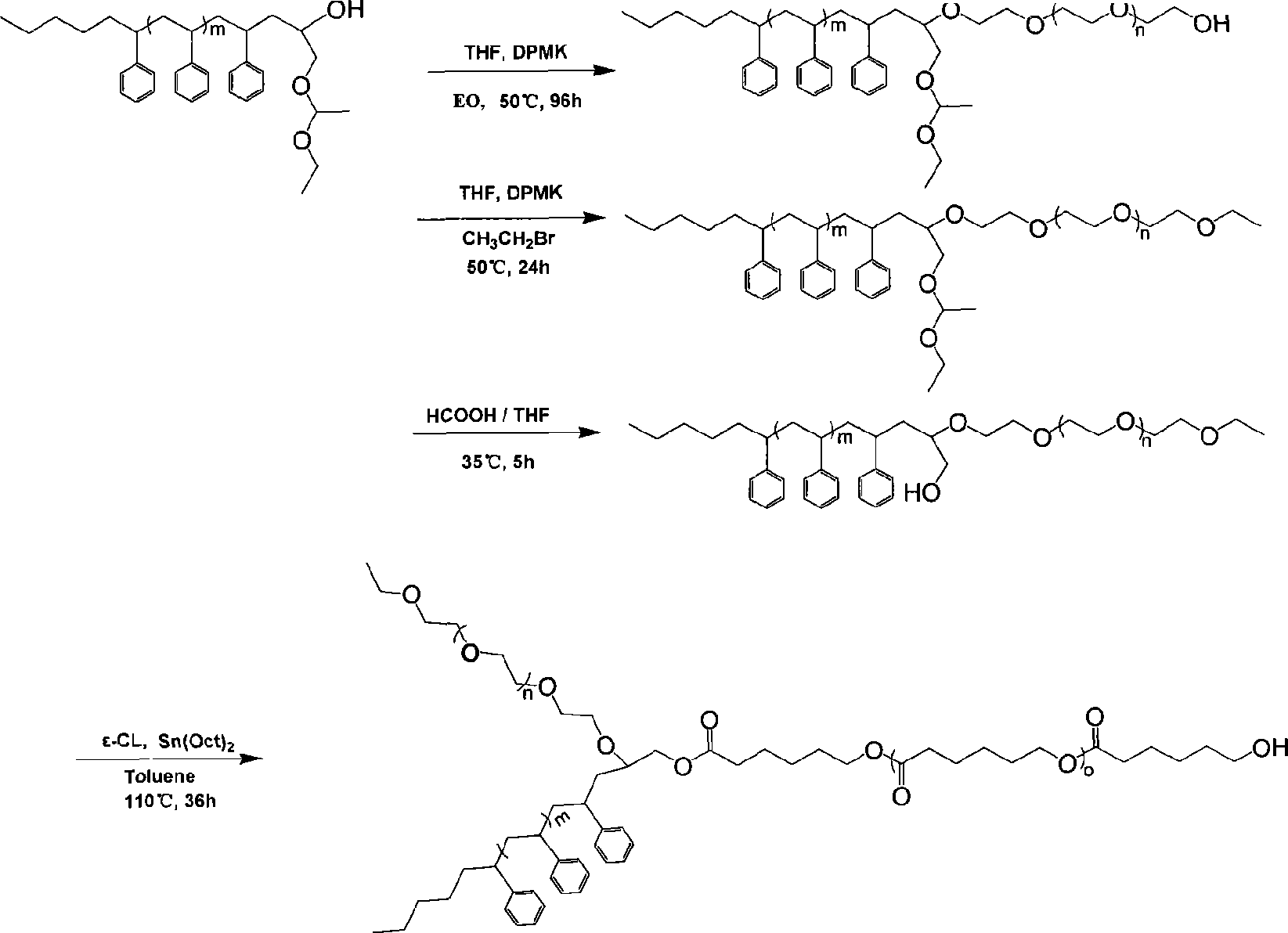

[0032] 1. Preparation of block polymer polystyrene-b-polyethylene oxide (PS-b-PEO) containing protected hydroxyl groups in the middle of the chain segment

[0033] First, 3.91g (1.40 mmol, M n(SEC)=2,800g / mol) end group functionalized polystyrene macroinitiator in toluene to remove water azeotropically. Then dissolve it in 100mLTHF and add it into a 250mL dry and clean (baked under infrared lamp for 2h) ampoule bottle, and fill it with high-purity nitrogen to make the internal and external pressure of the ampoule bottle basically equal. Slowly add a THF solution of diphenylmethyl potassium (DPMK) dropwise with a disposable syringe until the system turns dark yellow. The ampoule was then placed in an ice-water bath, and 7.2 mL (6.26 g) of ethylene oxide (EO) was injected rapidly. Slowly raise the temperature to 50°C and continue the reaction for 96 hours. After the reaction, PS-b-PEO with a protected hydroxyl group in the middle of the block polymer chain segment ...

Embodiment 2

[0040]

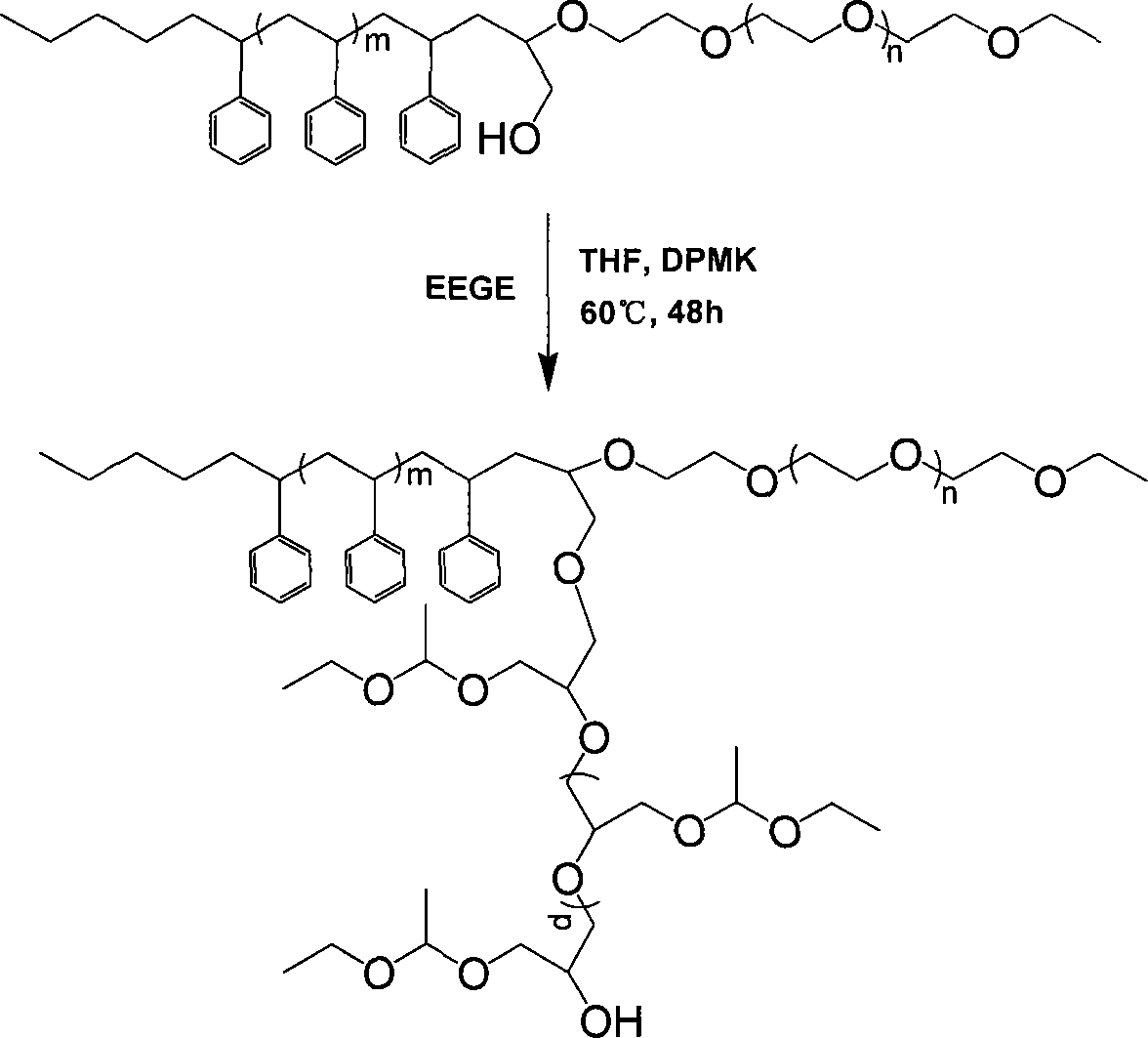

[0041] 1.20g (0.17mmol, M n(NMR) =7,100g / mol) block polymer PS-b-PEO into a 50mL ampoule, then add (45mL) toluene to remove water azeotropically, extract the solvent under vacuum, seal the cork tightly, and freeze in a vacuum system— Pump-thaw cycle three times. Then add a certain amount of THF, DPMK (5mL) and 1-ethoxyethyl glycidol (EEGE, 0.9mL, 0.90g) sequentially with a disposable syringe, seal it and place it in an oil bath at 60°C for 48h. After cooling to room temperature, the crude product was dissolved in tetrahydrofuran, precipitated in petroleum ether (30-60° C.), and filtered. The obtained product was dried in a vacuum oven at 45° C. for 12 h to constant weight to obtain a triblock star heteroarm polymer star (PS-PEO-PEEGE).

Embodiment 3

[0043]

[0044] Identical to the removal process of the protective group in Example 1, the protective group on the PEEGE segment in the triblock star heteroarm polymer star (PS-PEO-PEEGE) in Example 2 is removed, and then Precipitate in petroleum ether (30-60°C), and dry in a vacuum oven at 45°C for 12h to constant weight to obtain a triblock star heteroarm polymer star (PS-PEO-PG).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com