Method for producing natural antiseptic agent midbody with blueberry leaf and uses thereof

A technology of natural preservatives and black rice leaves, which is applied in the fields of application, edible seed preservation, meat/fish preservation with chemicals, etc., can solve the problems of high production cost of natural preservatives, restrictions on wide application, and few varieties, etc. Low cost, simple production process, easy to obtain materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

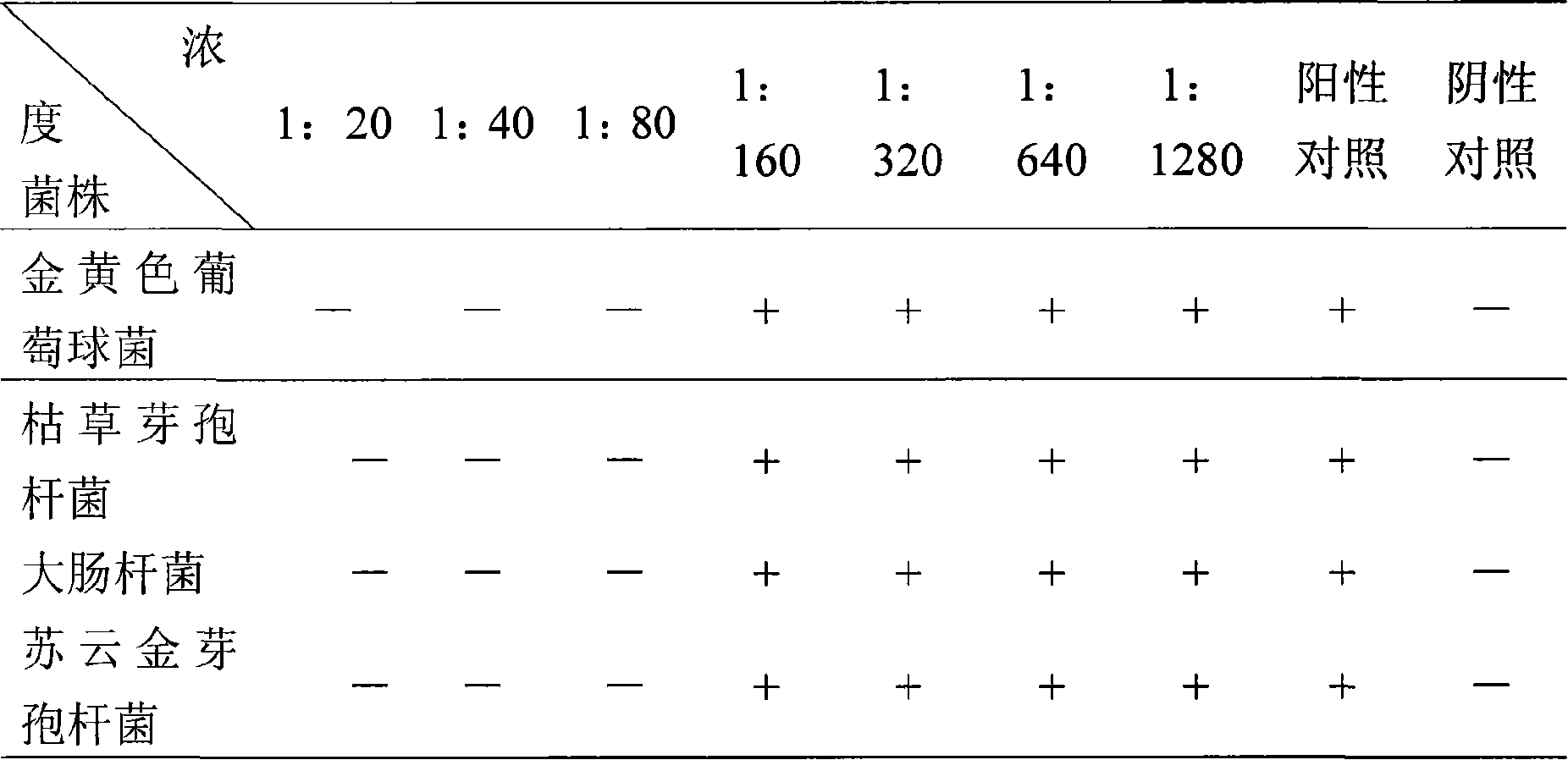

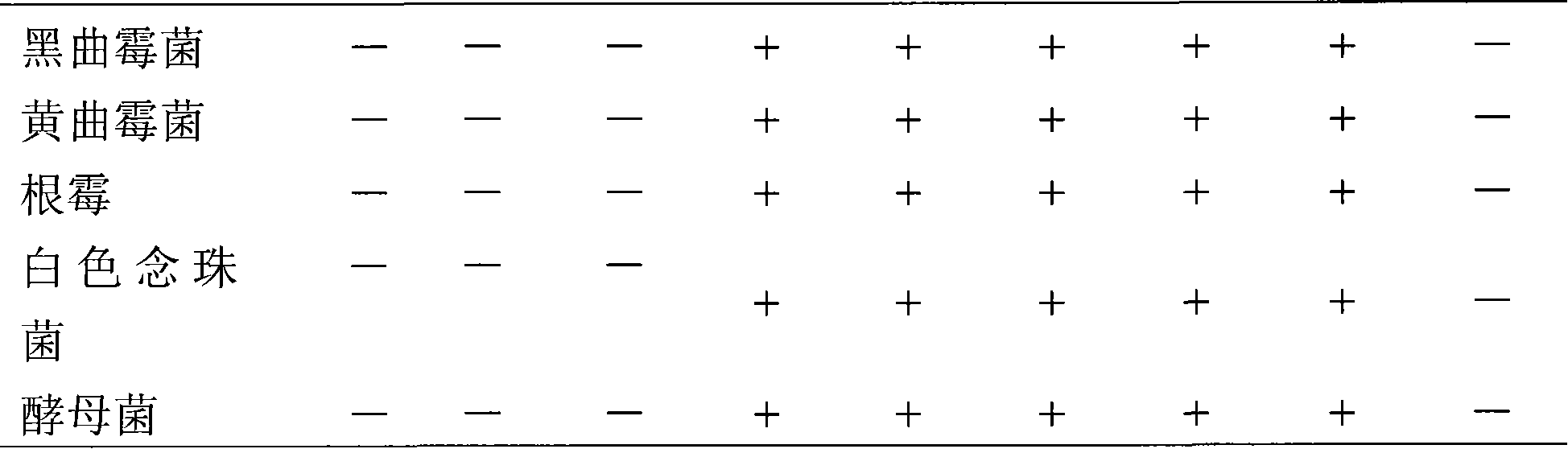

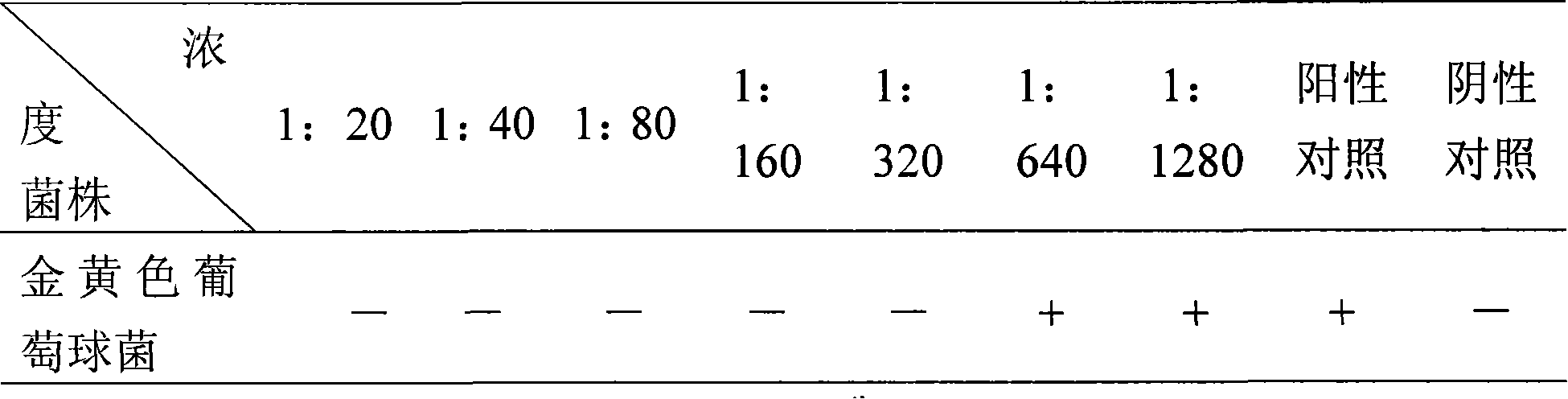

Method used

Image

Examples

Embodiment 1

[0012] Add 6 times of 30% ethanol to the leaves of the black rice tree, heat and reflux for extraction once, 0.5 hours each time, filter the extract, combine, concentrate to 0.25g crude drug / mL, pass through the AB-8 macroporous resin column after filtration, the leaves of the black rice tree and The weight ratio of AB-8 macroporous resin is 1:1, the upper column flow rate is 1BV / h, and the diameter-to-height ratio of the resin column is 1:3; the resin is washed with water for 3BV, the elution flow rate is 2BV / h, and the water eluent is discarded ; elute with 30% ethanol, the flow rate is 2BV / h, collect the ethanol eluate; concentrate the ethanol solution under reduced pressure, and dry under reduced pressure to obtain the leaf extract of Aurantia japonica, which is pulverized to obtain a natural preservative intermediate. The total flavonoid content of the intermediate is 20% (UV method, in terms of orientin or isoorientin, weight percent); orientin content is 1% (HPLC method,...

Embodiment 2

[0014] Add 12 times of 95% ethanol to the leaves of black rice tree, cold soak 4 times, 12 hours each time, filter the extract, combine, concentrate to 1.0g crude drug / mL, pass through D after centrifugation 101 Macroporous resin columns, black rice leaves and D 101 The weight ratio of the macroporous resin is 1:5, the upper column flow rate is 4BV / h, and the diameter-to-height ratio of the resin column is 1:9; the resin is washed with water for 8BV, and the elution flow rate is 4BV / h, and the water eluent is discarded; % ethanol elution, the flow rate is 4BV / h, collect the ethanol eluent; the ethanol solution is concentrated under reduced pressure, reduced pressure or spray drying, to obtain the leaf extract of Aegina japonica, and the extract is pulverized to obtain a natural preservative intermediate. The total flavonoid content of the intermediate is 90% (UV method, based on orientin or isoorientin, weight percent); orientin content is 12% (HPLC method, weight percent); is...

Embodiment 3

[0016] Add 8 times 70% ethanol to the leaves of black rice tree, cold soak 3 times, 8 hours each time, filter the extract, combine, concentrate to 0.5g crude drug / mL, pass through D after centrifugation 101 Macroporous resin columns, black rice leaves and D 101 The weight ratio of the macroporous resin is 1:3, the upper column flow rate is 2BV / h, and the diameter-to-height ratio of the resin column is 1:5; the resin is washed with water for 5BV, and the elution flow rate is 3BV / h, and the water eluent is discarded; % ethanol elution, the flow rate is 3BV / h, collect the ethanol eluent; the ethanol solution is concentrated under reduced pressure, reduced pressure or spray drying, to obtain the leaf extract of Aurantia japonica. The extract is pulverized to obtain the intermediate of natural preservatives. The total flavonoid content of the intermediate is 50% (UV method, based on orientin or isoorientin, weight percent); orientin content is 8% (HPLC method, weight percent); isor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com