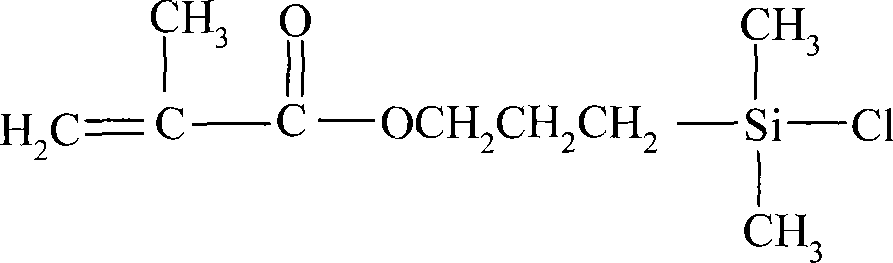

Method for preparing methyl acryloyl o-propyl dimethylchlorosilane

A technology for methacryloyloxypropyl dimethyl chlorosilane and dimethyl chlorosilane is applied in the field of preparing methacryloyloxypropyl dimethyl chlorosilane, and can solve the problem of the temperature rise of the reaction system and the large amount of by-products. , poor selectivity and other problems, to achieve the effect of mild conditions, easy recovery and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

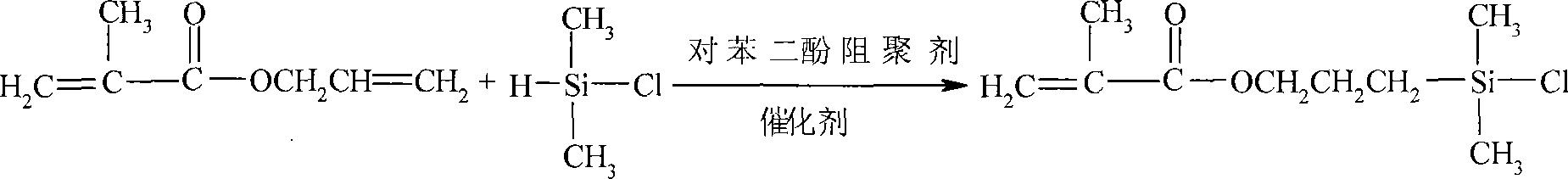

Method used

Image

Examples

Embodiment 1

[0018] (1) SiO 2 The preparation of supported type chloroplatinic acid catalyst: in the reaction vessel with stirring, add 1g hexahydrate chloroplatinic acid respectively, 120ml isopropanol aqueous solution (isopropanol and deionized water are prepared in a volume ratio of 1:5), 75.25g dried SiO 2 Stir well at room temperature, and after standing for 24 hours, evaporate the contained water at 130 ° C to obtain 73.5 g of SiO containing 1% chloroplatinic acid (mass ratio). 2 Supported chloroplatinic acid catalyst.

[0019] (2) Add 12.6g (0.10mol) allyl methacrylate, 0.1g (0.0009mol) hydroquinone and 0.17g SiO to the reactor equipped with reflux condenser, stirrer and thermometer respectively 2 Supported chloroplatinic acid catalyst, introduce nitrogen gas at the same time, under nitrogen atmosphere, heat to 50~53 ℃, slowly add dropwise the mixed solution of 44g allyl methacrylate and dimethyl chlorosilane (allyl methacrylate / Preparation of dimethylchlorosilane mixed solution...

Embodiment 2

[0021] (1) SiO 2 The preparation of the supported chloroplatinic acid catalyst is the same as in Example 1.

[0022] (2) Add 37.8g (0.30mol) allyl methacrylate, 0.1g (0.0009mol) hydroquinone, 0.17g SiO to the reactor equipped with reflux condenser, stirrer and thermometer respectively 2 Supported chloroplatinic acid catalyst, introduce nitrogen at the same time, under nitrogen atmosphere, heat to 50~55 ℃, slowly add dropwise the mixed solution of 44g allyl methacrylate and dimethyl chlorosilane (allyl methacrylate / Preparation of dimethylchlorosilane mixed solution: 25.2g (0.2mol) allyl methacrylate and 18.8g (0.2mol) dimethylchlorosilane are mixed at room temperature in a molar ratio of 1:1 and stirred evenly), Control and maintain the reaction temperature at 60-70°C. Continue to drop 28.4g (0.3mol) dimethyl chlorosilane to react for 2 hours, distill the obtained reaction solution under reduced pressure, collect 116~120°C / 10mm Hg fraction, and obtain 94.8g methacryloxypropy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com