A ferrite material and method for preparing same

A ferrite material and ferrite technology, applied in the field of materials, can solve the problems of not disclosing the composition range of magnetic composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

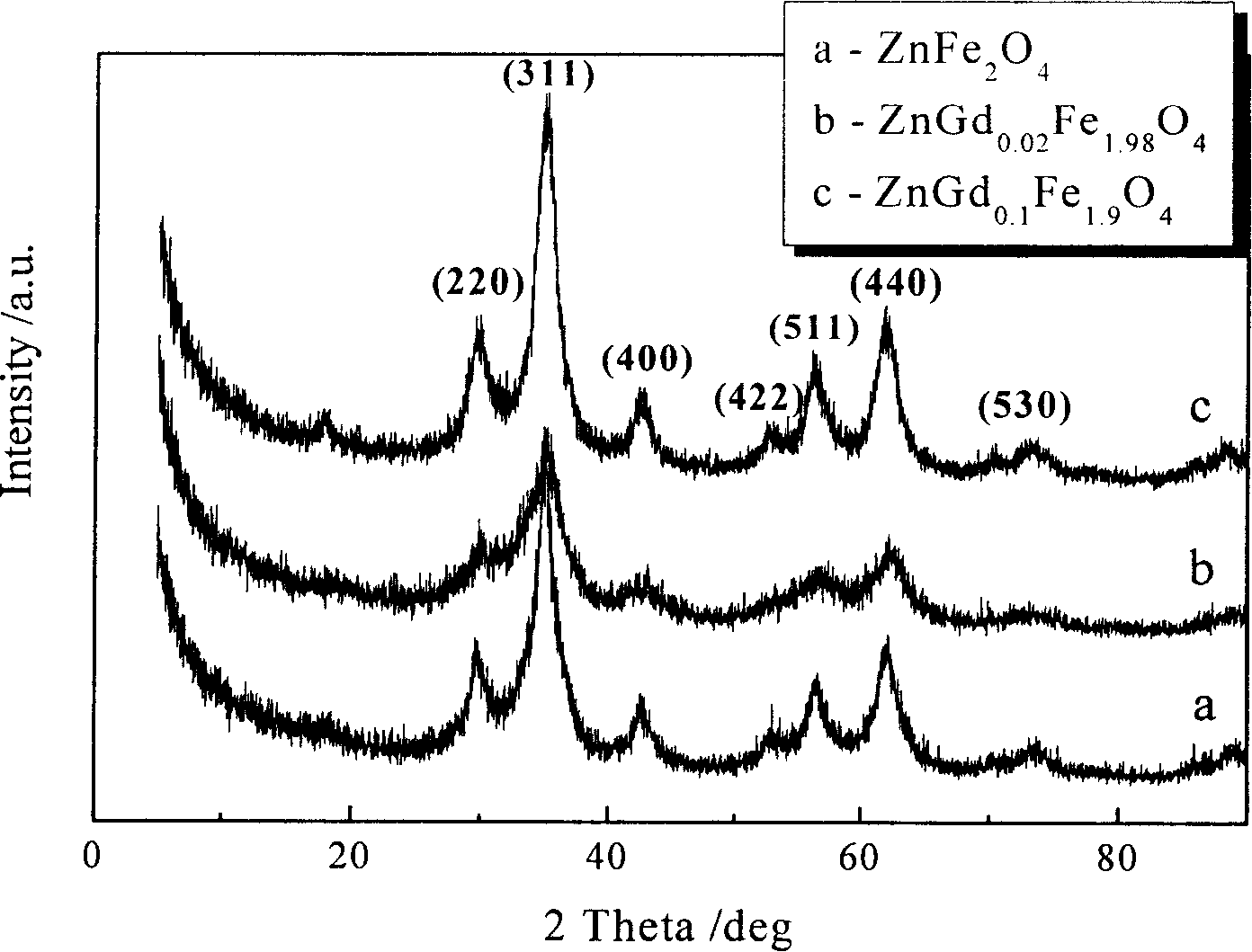

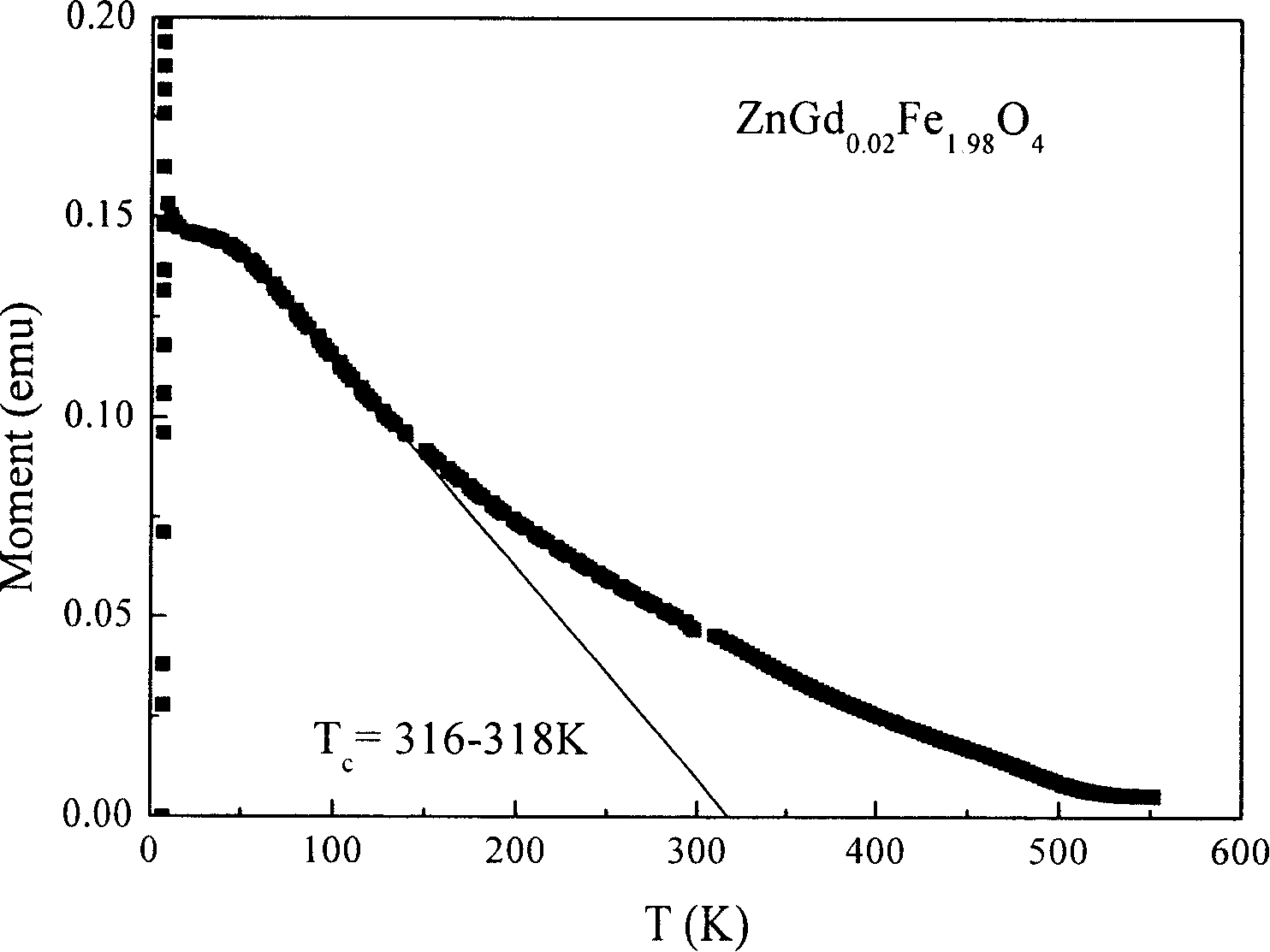

[0023] Example 1. ZnGd with a Curie temperature of 43-45°C 0.02 Fe 1.98 o 4 Preparation of ferrite

[0024]Measure 50mL of zinc chloride aqueous solution with a concentration of 0.1mol / L, 99mL of an aqueous solution of ferric chloride with a concentration of 0.1mol / L, and 1mL of an aqueous solution of gadolinium chloride with a concentration of 0.1mol / L to make a uniform mixed solution, and quickly add it to In 50 mL of sodium hydroxide solution with a concentration of 5 mol / L, under stirring at a speed of 180 rpm, the reaction temperature was kept at 90°C. After 1 hour of reaction, the gel-like precipitated product was placed in ice water to be quenched, and then The precipitated product was repeatedly washed with deionized water until neutral (pH=7), filtered through filter paper, and freeze-dried at -48°C for 5 hours to make gadolinium-containing ferrite powder. The zinc oxide content in its chemical composition was 20wt %, the content of iron oxide is 78wt%, and the con...

Embodiment 2

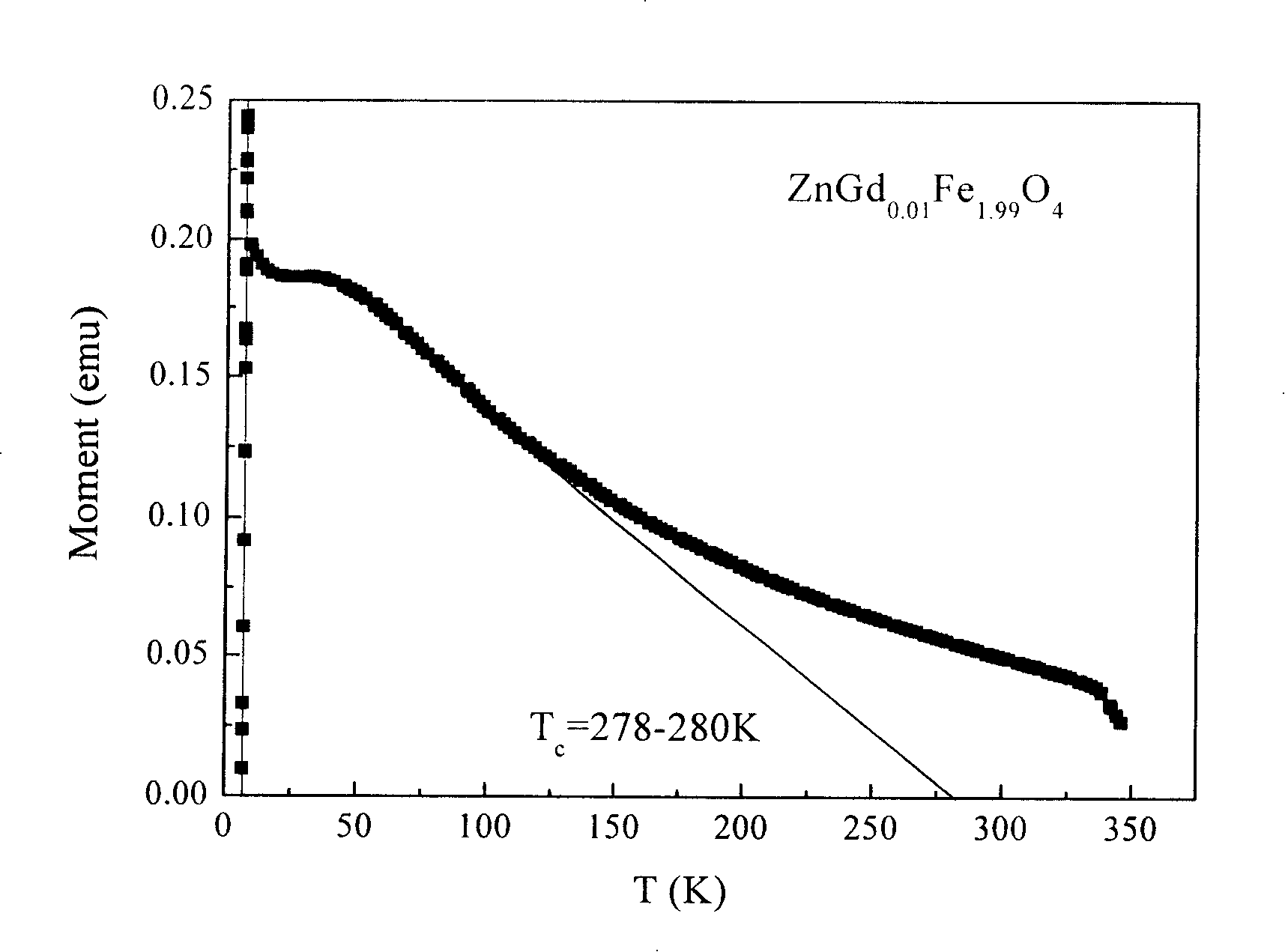

[0025] Embodiment 2. Curie temperature is ZnGd of 5~7 ℃ 0.01 Fe 1.99 o 4 Preparation of ferrite

[0026] Measure 50mL of zinc sulfate aqueous solution with concentration of 0.1mol / L, 99.5mL of ferric sulfate aqueous solution of 0.1mol / L, and 0.5mL of gadolinium nitrate aqueous solution of 0.1mol / L to make a uniform mixed solution, and quickly add it to a concentration of 5mol / L of 50mL potassium hydroxide solution, under the stirring speed of 180 rpm, keep the reaction temperature at 90°C, after 1h of reaction, place the gel-like precipitated product in ice water to quench, centrifuge to obtain the precipitated product, Then the precipitated product was repeatedly washed with deionized water to neutrality (pH=7), filtered, and freeze-dried at -48°C for 5 hours to make zinc-gadolinium ferrite powder with a Curie temperature of 5-7°C. The chemical composition The zinc oxide content in the medium is 20wt%, the iron oxide content is 79wt%, and the gadolinium oxide content is 1...

Embodiment 3

[0027] Example 3. ZnGd with a Curie temperature of 120°C 0.1 Fe 1.9 o 4 Preparation of ferrite

[0028] Measure 50mL of zinc nitrate aqueous solution with a concentration of 0.1mol / L, 90mL of an aqueous solution of ferric nitrate with a concentration of 0.1mol / L, and 10mL of an aqueous solution of gadolinium nitrate with a concentration of 0.1mol / L to make a uniform mixed solution, and quickly add to the concentration of In 50mL potassium hydroxide solution of 5mol / L, keep the reaction temperature at 90°C under stirring at a rotation speed of 180 rpm. After 1 hour of reaction, place the gel-like precipitated product in ice water to quench and centrifuge to obtain the precipitate product, and then the precipitated product was repeatedly washed with deionized water to neutrality, filtered, and freeze-dried at -48°C for 5 hours to make zinc-gadolinium ferrite micropowder with a Curie temperature of 120°C for tumor magnetic hyperthermia, particle size 10-30nm (for powder morpho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com