Novel process for synthesizing povidone iodine by gas phase/ solid phase reaction

A solid-phase reaction, povidone-iodine technology, applied in the direction of artificially synthesized active ingredients of polymeric materials, drug combinations, skin diseases, etc., can solve the problems of high cost of iodine raw materials, high requirements for refined iodine purity and particle size uniformity, etc. , to achieve the effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

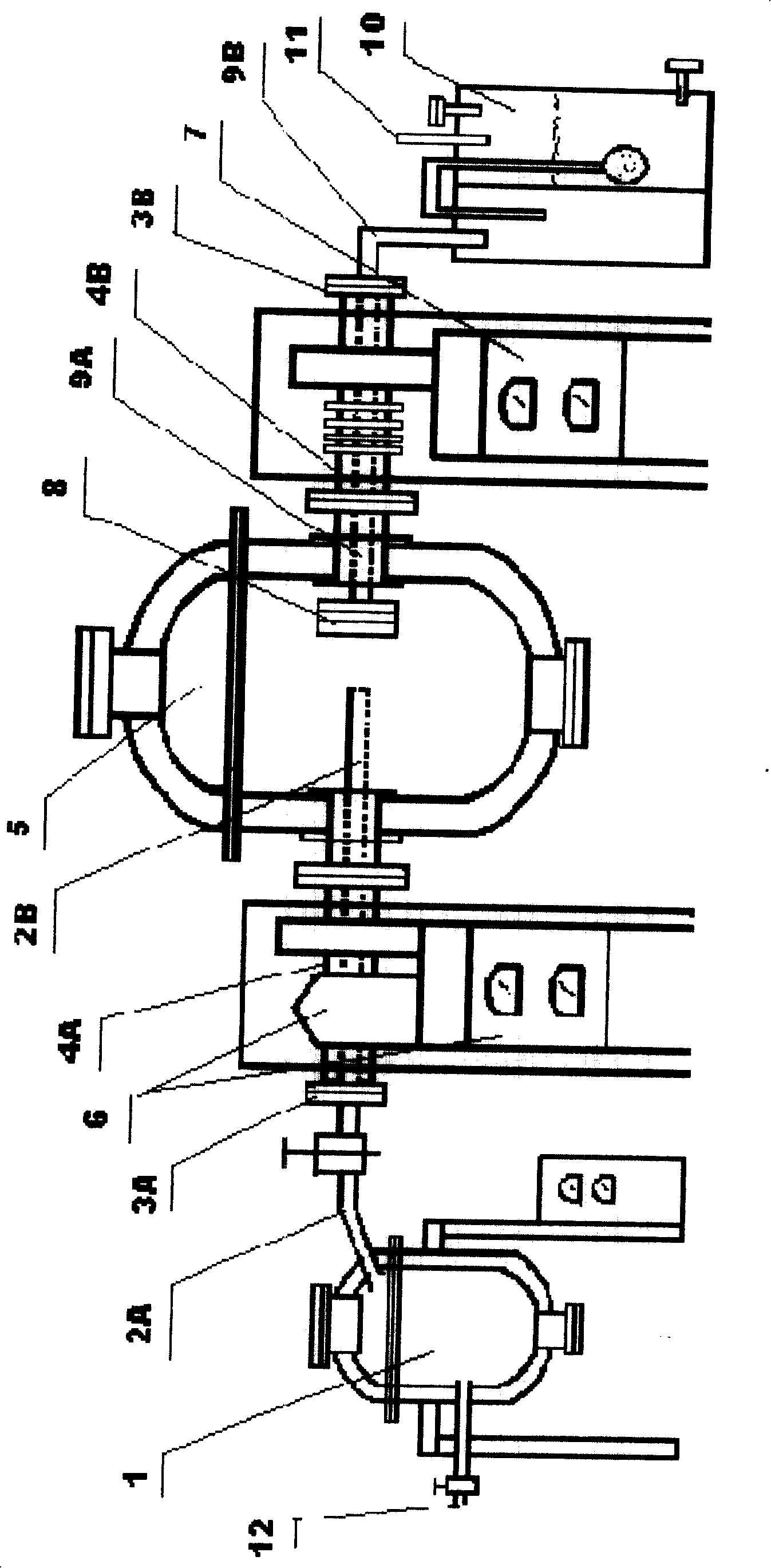

[0011] Use the gas-phase / solid-phase reactor of the synthetic povidone-iodine shown in accompanying drawing, in the iodine sublimation tank (1), pack the thick iodine 17Kg (containing iodine 15.5kg) containing iodine content 90%, seal charging port; Pack polyvinylpyrrolidone (model K30) 85kg in gas phase / solid phase reaction tank (5); In exhaust gas collection tank (10), pack 50kg of 5% sodium thiosulfate aqueous solution, and add 50ml concentration and be 1% starch The solution is used as an indicator; the iodine sublimation tank is heated to 100-120°C to sublimate the iodine, and the maintenance temperature is between 100-120°C; the iodine vapor is introduced into the rotating gas phase / solid phase reaction tank ( 5), fully mixed, adsorbed, and reacted with polyvinylpyrrolidone; through the transmission control device (6), the gas phase / solid phase reaction tank (5) was kept at a rotational speed of 10-20 revolutions per minute, and according to 20-30 minutes period, change ...

Embodiment example 2

[0013] Use the gas phase / solid phase reaction equipment shown in Fig. 1, in the iodine sublimation tank (1), pack the thick iodine 20.0Kg (containing iodine 18.0kg) containing iodine content 90%, seal charging port; In gas phase / solid phase Pack polyvinylpyrrolidone (model K30) 100kg in reaction tank (5); Pack 50kg of 5% sodium thiosulfate aqueous solution in waste gas collecting tank, and add 50ml concentration and be that 1% starch solution makes indicator; Heating iodine sublimation tank (1) Iodine is sublimated to 100-114°C, and the maintenance temperature is between 100°C and 120°C; iodine vapor is introduced into the rotating gas phase / solid phase reaction tank (5) through an insulated conduit (2A-2B), and is mixed with poly Vinylpyrrolidone is fully mixed, adsorbed, and reacted; at the same time, nitrogen is introduced into the iodine sublimation tank (1) through the conduit (12) as a carrying gas, and the nitrogen flow rate is controlled at 10-50 liters / minute to speed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com