Organic water-proof oil-resist finishing agent for paper and cardboard and preparation thereof

A water-repellent, oil-repellent, organic fluorine technology, applied in the direction of water-repellent addition, anti-corrosion agent/anti-oxidant addition, etc., can solve the problems of lower ignition point of water-based dispersion liquid, increase of VOC value, unfavorable environment, etc., and achieve small emulsion particle size , low cost and high safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

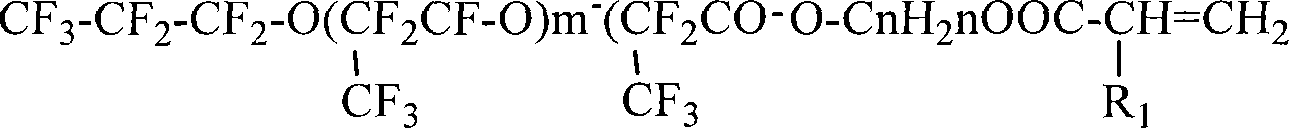

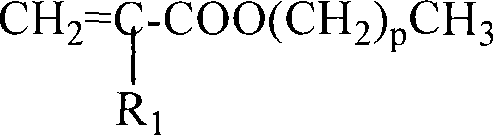

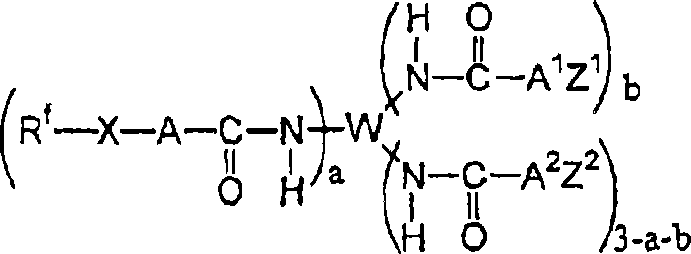

Method used

Image

Examples

Embodiment 1

[0050] 120g octadecyl methacrylate, 165g hexafluoropropylene oxide trimer hydroxypropyl methacrylate, 15g hydroxypropyl methacrylate, 24g compound emulsifier with HLB value of 12.0, 0.4 dodecyl mercaptan g was added to a 2000ml flask, heated at 50°C to melt and pre-emulsified with 550g of water dripped continuously to form an O / W emulsion, and finally the initiator (2.4g potassium persulfate) was added dropwise under the inert condition of nitrogen protection The initiator was polymerized with 50 g of aqueous solution) for 5.5 hours to obtain a water- and oil-repellent finishing agent emulsion for paper and cardboard.

[0051] Dilute the emulsion with a solid content of about 20% to 3%, then soak the paper in the diluted emulsion for 1 to 3 minutes, dry it at 120°C, cool to room temperature, and test the water repellency to reach 90 points.

Embodiment 2

[0053] 150g octadecyl methacrylate, 135g hexafluoropropylene oxide trimer hydroxypropyl methacrylate, 15g hydroxypropyl methacrylate, 24g compound emulsifier with HLB value of 12.0, 0.4 dodecyl mercaptan g is added to a 2000ml flask, heated at 50°C to melt and pre-emulsified with 550g of water dripped continuously to form an O / W emulsion, and finally the initiator (2.6g persulfur to 50g aqueous solution of ammonium initiator) polymerized for 5 hours to obtain the water and oil repellent finishing agent emulsion for paper and cardboard.

[0054] Dilute the emulsion with a solid content of about 20% to 3%, then soak the paper in the diluted emulsion for 1 to 3 minutes, dry it at 120°C, and cool it to room temperature.

Embodiment 3

[0056] With 80g octadecyl methacrylate, 80 gram cetyl acrylate, 135g hexafluoropropylene oxide trimer hydroxyethyl methacrylate, 15g hydroxypropyl methacrylate, HLB value 12.0 composite emulsifier 24g, Add 0.4g of dodecyl mercaptan to a 2000ml flask, heat it at 50°C to melt it, and add 550g of water continuously for pre-emulsification to form an O / W emulsion. agent (2.5g of potassium persulfate in 50g of aqueous solution) was polymerized for 6 hours to obtain a water- and oil-repellent finishing agent emulsion for paper and cardboard.

[0057] Dilute the emulsion with a solid content of about 20% to 3%, then soak the paper in the diluted emulsion for 1 to 3 minutes, dry it at 120°C, cool to room temperature, and test the water repellency to reach 90 points.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com