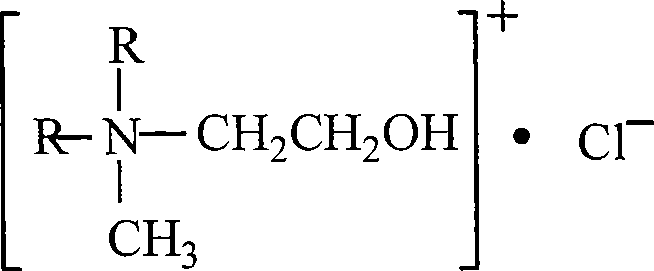

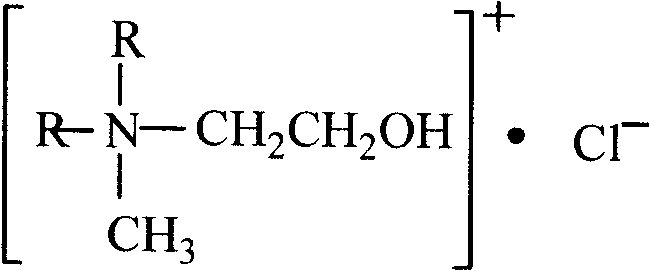

Bialkyl methyl ethoxyl quaternary ammonium salt and synthesis method thereof

A technology of alkyl methyl hydroxyethyl and synthesis method is applied in the field of dialkyl methyl hydroxyethyl quaternary ammonium salt and its synthesis, and achieves the effects of excellent biodegradability, short reaction time and good environmental compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Weigh double C 10 Put 63g of alkylmethyl tertiary amine, 30g of water, and 60g of absolute ethanol into a four-neck flask; weigh 45g of hydrochloric acid with a mass concentration of 20%, and put it into a constant pressure dropping funnel. Under the condition of stirring and keeping the temperature at 30°C, hydrochloric acid was slowly added dropwise into the four-necked flask for 30 minutes. When the hydrochloric acid was added dropwise, the stirring was continued for 10 min. The resulting product was put into the autoclave, and the 2 Replace 3 times. Under the condition of constant stirring, the temperature was raised to 60° C., and then 10 g of ethylene oxide was introduced, reacted for 1.5 h under a pressure of 0.15 MPa, and aged for 2 h. Finally, the content of the quaternary ammonium salt active substance in the product was measured to be 36.3%.

Embodiment 2

[0020] Weigh double C 12 Put 100 g of alkylmethyl tertiary amine, 70 g of water, and 80 g of methanol into a four-neck flask; weigh 50 g of hydrochloric acid with a mass concentration of 20%, and put it into a constant pressure dropping funnel. Under the condition of stirring, the reaction temperature was kept at 40° C., and hydrochloric acid was slowly added dropwise into the four-neck flask for 20 minutes. When the hydrochloric acid is added dropwise, continue to stir for 10 min, then put the resulting product into the autoclave, and use N 2 Replace 3 times. Under the condition of constant stirring, the temperature was raised to 50° C., 15 g of ethylene oxide was passed through, the reaction was carried out under the pressure of 0.05 MPa for 1 h, and the aging was continued for 2 h. Finally, the content of the quaternary ammonium salt active substance in the product was measured to be 37.5%.

Embodiment 3

[0022] Weigh double C 12~14 Put 73g of alkylmethyl tertiary amine, 40g of water, and 60g of isopropanol into a four-neck flask; weigh 25g of hydrochloric acid with a mass concentration of 35%, and put it into a constant pressure dropping funnel. Under the condition of stirring and keeping the temperature at 35°C, hydrochloric acid was slowly added dropwise into the four-necked flask for 60 minutes. When the hydrochloric acid is added dropwise, continue to stir for 10 min. The resulting product is put into the autoclave, and 2 Replace 3 times. Under the condition of constant stirring, the temperature was raised to 70° C., and then 9 g of ethylene oxide was introduced, reacted for 0.5 h under a pressure of 0.15 MPa, and aged for 2 h. Finally, the content of the quaternary ammonium salt active substance measured in the product is 38.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com