Laser array micro-pore forming device and method

A molding device, micro-hole technology, used in laser welding equipment, welding equipment, metal processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

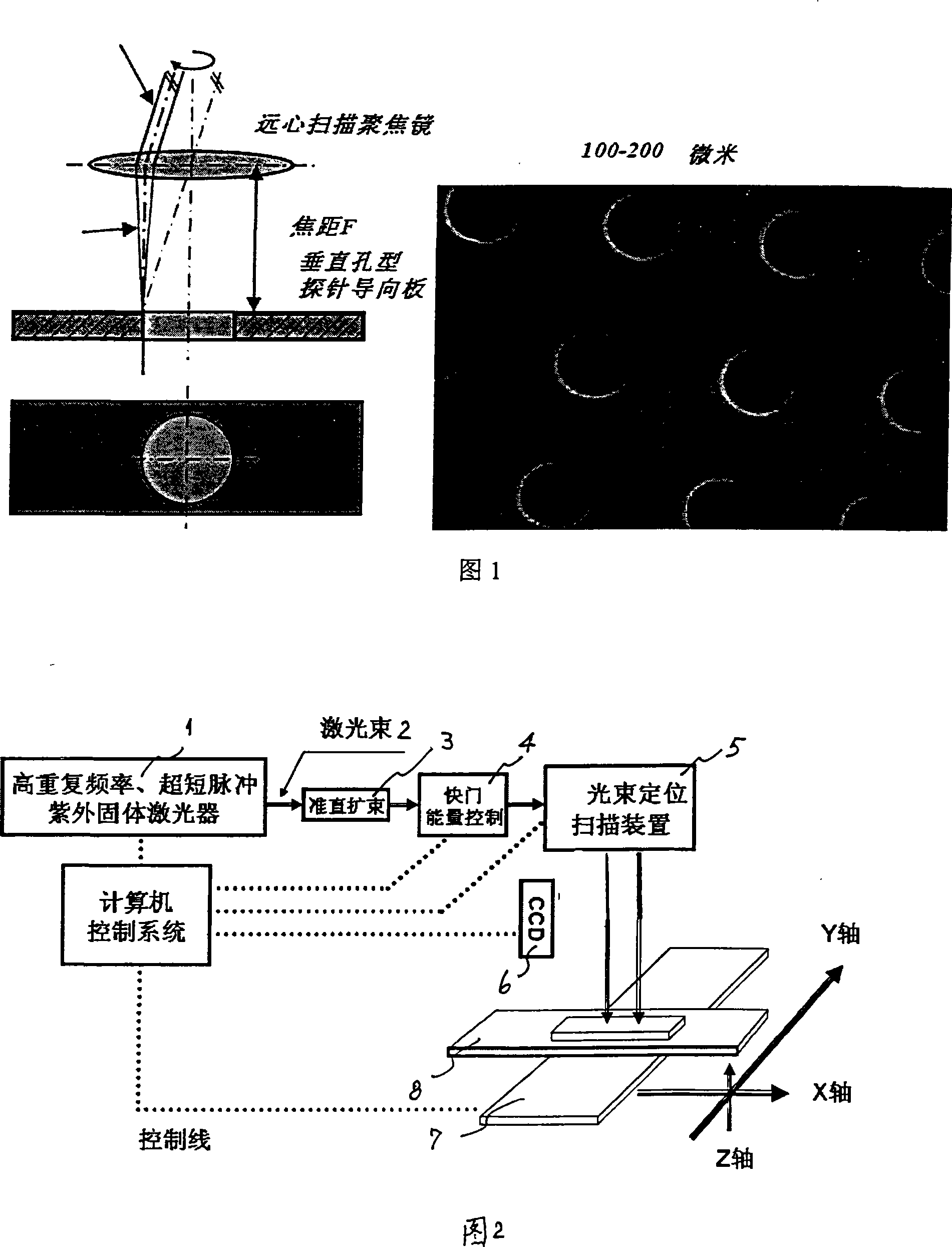

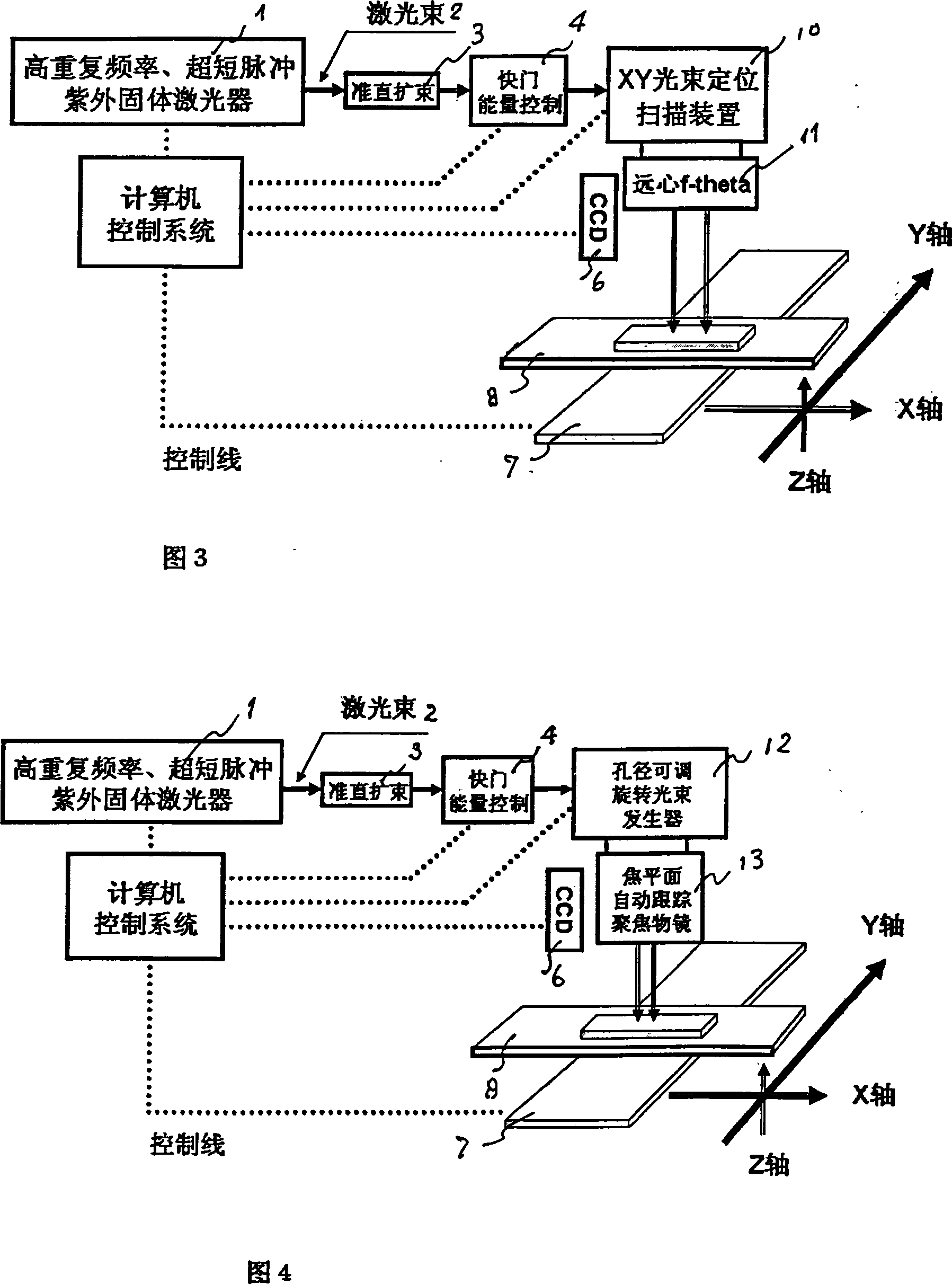

[0021] As shown in Figure 3, a laser array microhole forming device includes: high repetition rate, ultrashort pulse ultraviolet solid-state laser 1, laser beam generator 2, collimating beam expander 3, shutter 4 (laser energy controller ), the beam positioning and scanning device 5 is composed of an XY beam positioning scanner 10, a telecentric f-theta scanning focusing objective lens 11, a CCD vision alignment system 6, an XYZ (liftable) precision displacement work platform 7, a vacuum negative pressure Adsorption film rack 8, array of microporous workpieces 9.

Embodiment 2

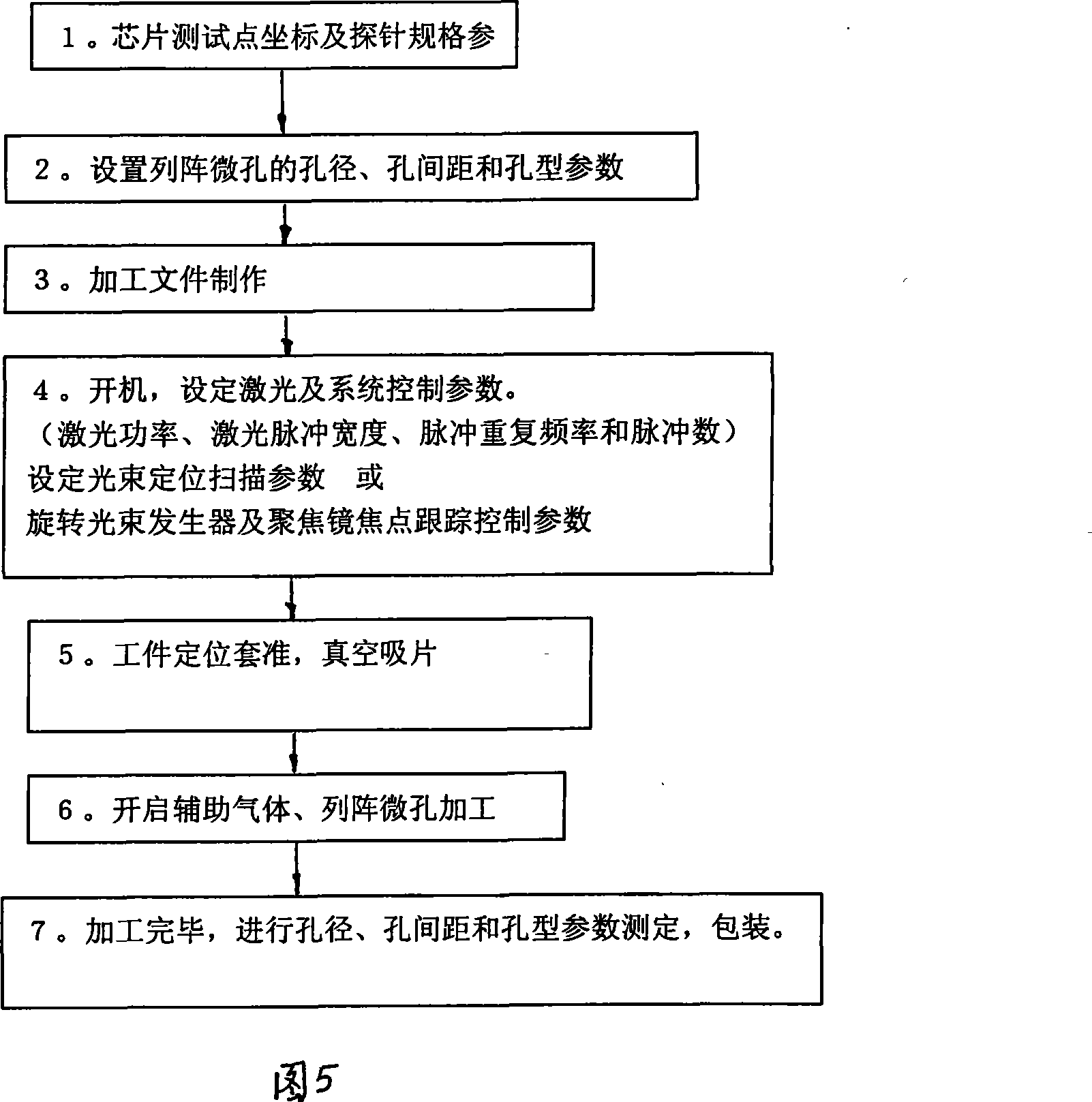

[0023] As shown in Figure 4, the laser array micro-hole forming device includes: a high repetition rate, ultra-short pulse ultraviolet solid-state laser 1, laser beam generator 2, collimating beam expander 3, shutter 4 (laser energy controller ), the beam positioning and scanning device 5 is composed of an adjustable aperture rotating beam generator 12, a focal plane automatic tracking and focusing objective lens 13, a CCD vision alignment system 6, an XYZ (liftable) precision displacement work platform 7, a vacuum negative pressure Adsorption film rack 8, array of microporous workpieces 9.

[0024] 1. Using telecentric f-theta focus scanning objective lens:

[0025] Set the required hole diameter, hole spacing and hole type parameters of the probe card array microplate, and make computer-controlled processing files: According to the required hole diameter, hole spacing, coordinate position and hole type parameters of the probe card array microplate , To form the control data file...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com