Reforming catalyst and application in high selectivity production of para-xylene of the same

A reforming catalyst and catalyst technology, applied in molecular sieve catalysts, physical/chemical process catalysts, organic chemistry, etc., can solve the problems of molecular sieve crystallization destruction, molecular sieve modification, reduction, etc., to reduce investment and operating costs, strong resistance to sulfur and nitrogen Poisoning ability, the effect of improving operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The preparation method of catalyst (E-1) of the present invention is as follows:

[0038] (1) Preparation of phosphorus-containing molecular sieves

[0039] a. Ammonium dihydrogen phosphate and water are used to prepare 1000 grams of phosphorus pentoxide concentration into a solution of 5 wt%, and the above solution is added to 950 grams of HZSM-5 (the molar ratio of silicon to aluminum is 65, and the specific surface area is 187m 2 / g, pore volume 0.18ml / g, provided by Nankai University), the mixture was dried for 8 hours, then in the air atmosphere at 550 ° C, roasted for 6 hours to obtain the ZSM-5 molecular sieve with a phosphorus pentoxide content of 5wt%, which is denoted as ZSM-5a.

[0040] B. same as step a, its difference is that the phosphorus-containing compound used is phosphoric acid, and the concentration of preparing phosphorus pentoxide is 9.5wt%, obtains the ZSM-5 molecular sieve that phosphorus pentoxide content is 9.5wt%, is denoted as ZSM here -5b....

Embodiment 2

[0047] The preparation method of catalyst (E-2) of the present invention is as follows:

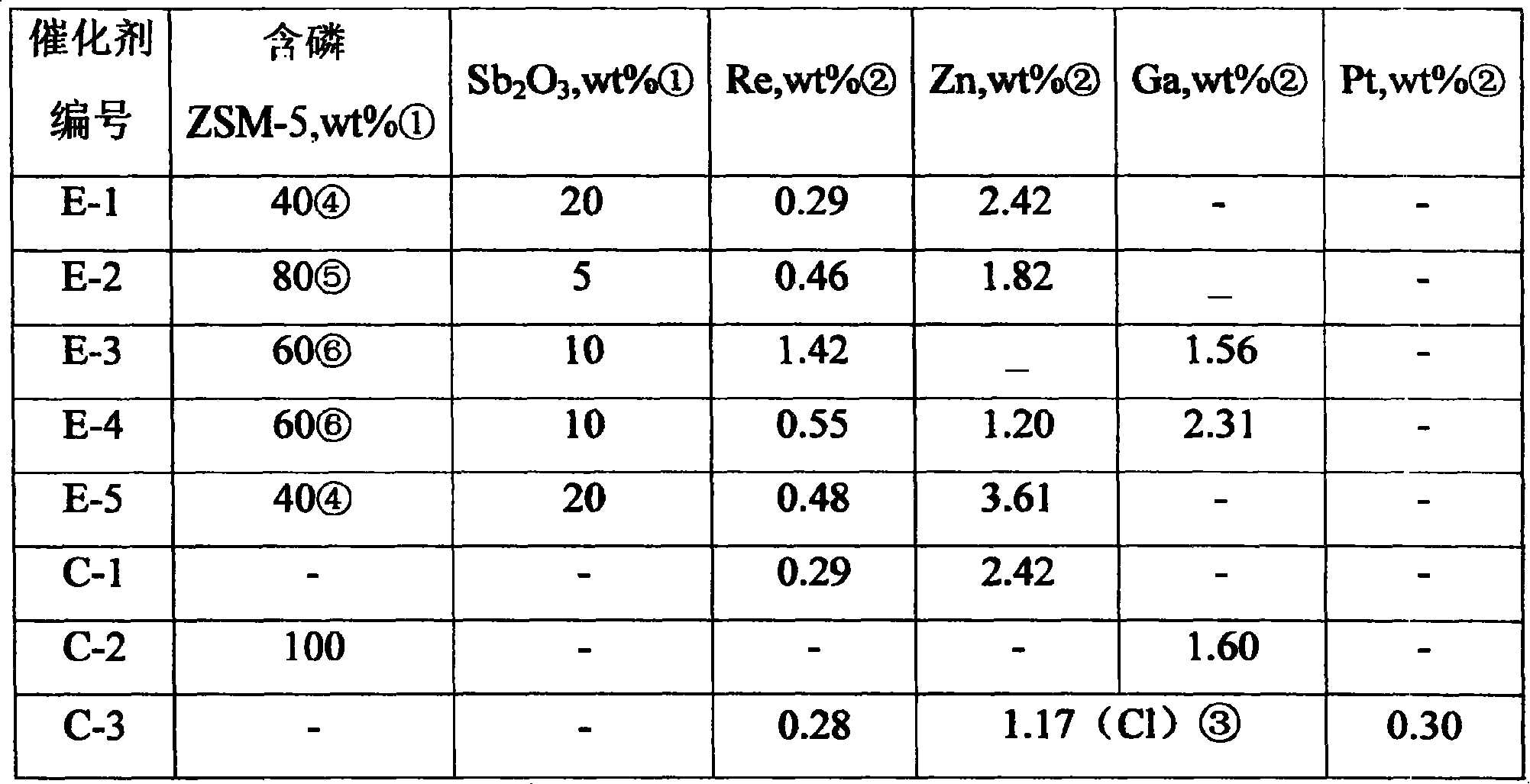

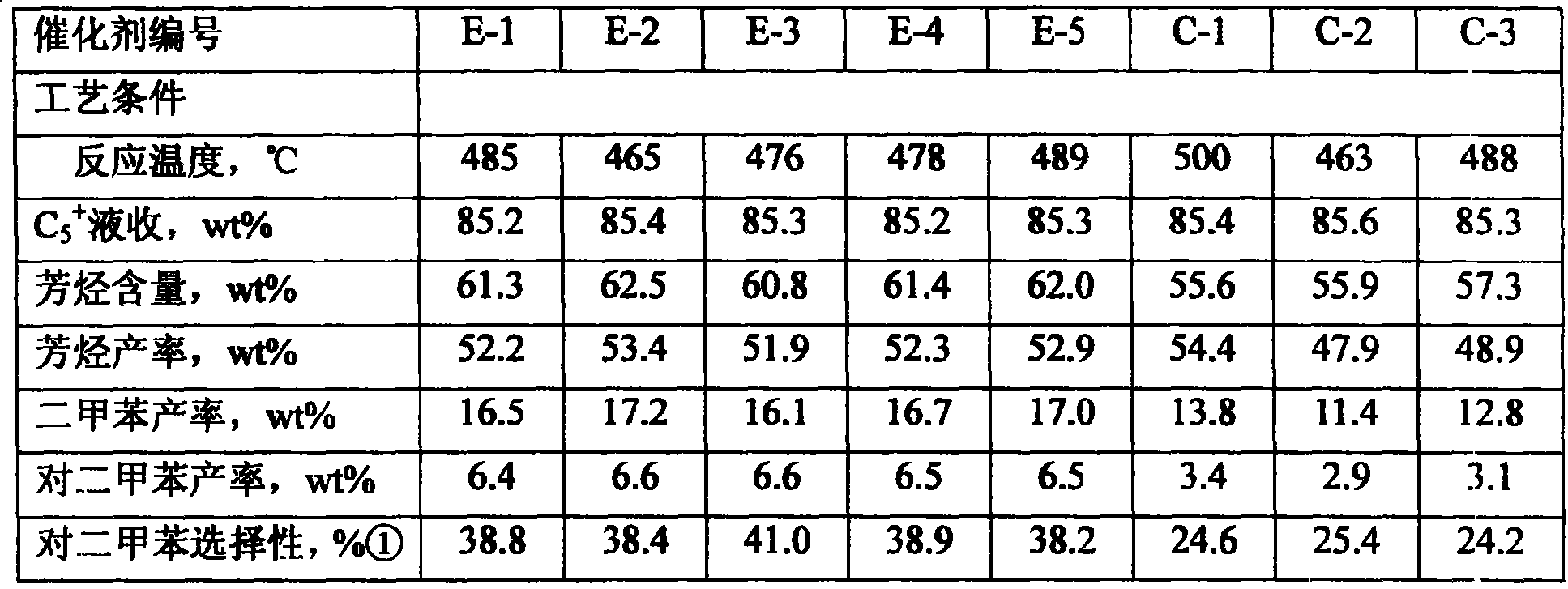

[0048] Catalyst preparation method is the same as embodiment 1, and difference is that molecular sieve used is ZSM-5b, and its content in catalyst carrier is 80wt%, Sb 2 o 3 The content of rhenium is 5wt%; the content of rhenium and zinc in the catalyst is different, and the catalyst number is E-2, its composition is shown in Table 1, and the evaluation results are shown in Table 2.

Embodiment 3

[0050] The preparation method of catalyst (E-3) of the present invention is as follows:

[0051] Catalyst preparation method is the same as embodiment 1, and difference is that molecular sieve used is ZSM-5c, and its content in catalyst carrier is 60wt%, Sb 2 o 3 The content of the catalyst is 10wt%; the active metals are rhenium and gallium, the compounds used are perrhenic acid and gallium nitrate respectively, and the obtained catalyst number is E-3, its composition is shown in Table 1, and the evaluation results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com