Hydroxyapatite micrometre tube and method of producing the same

A technology of hydroxyapatite and microtubes, applied in chemical instruments and methods, phosphorus compounds, medical science, etc., to achieve the effects of convenient operation, cost reduction, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

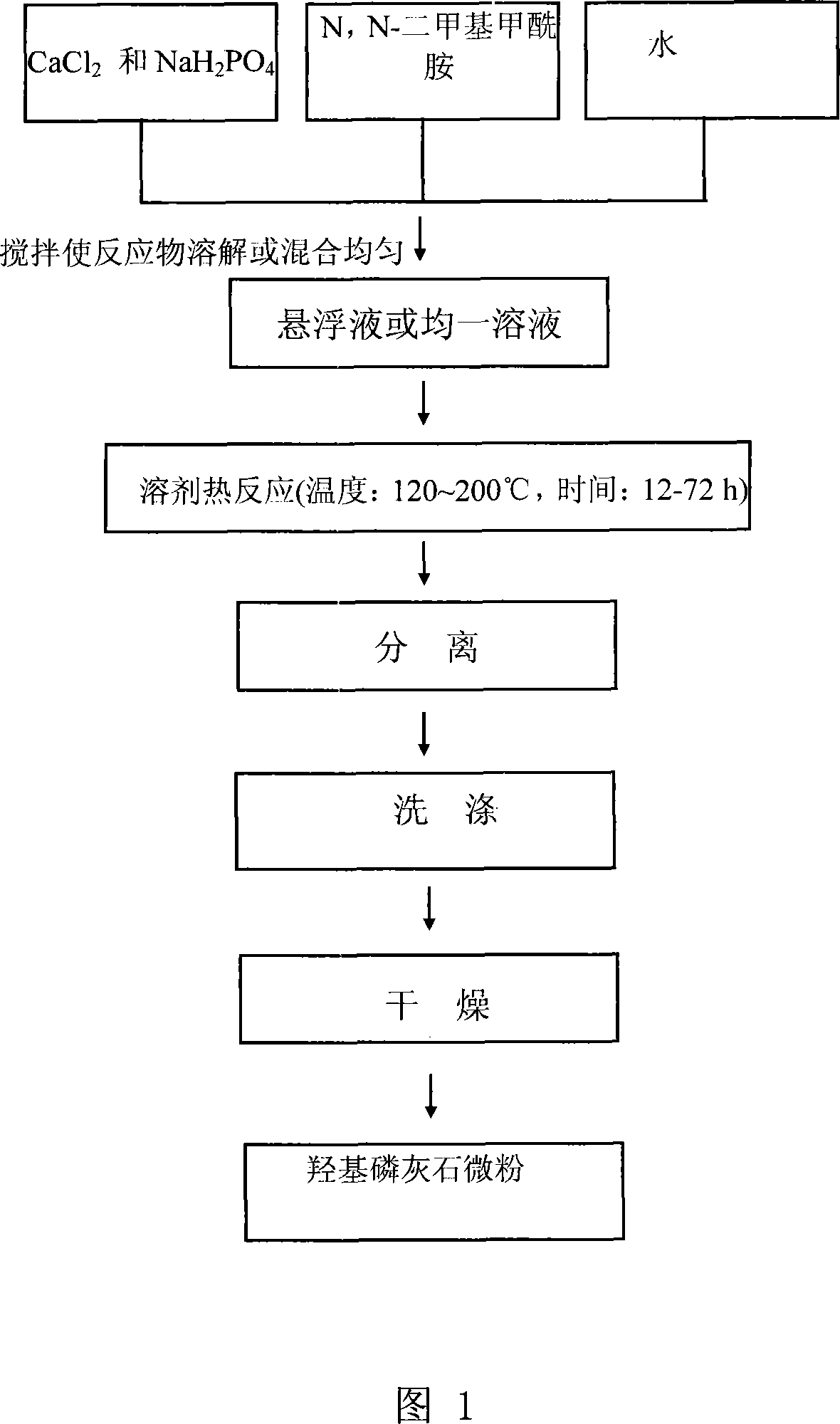

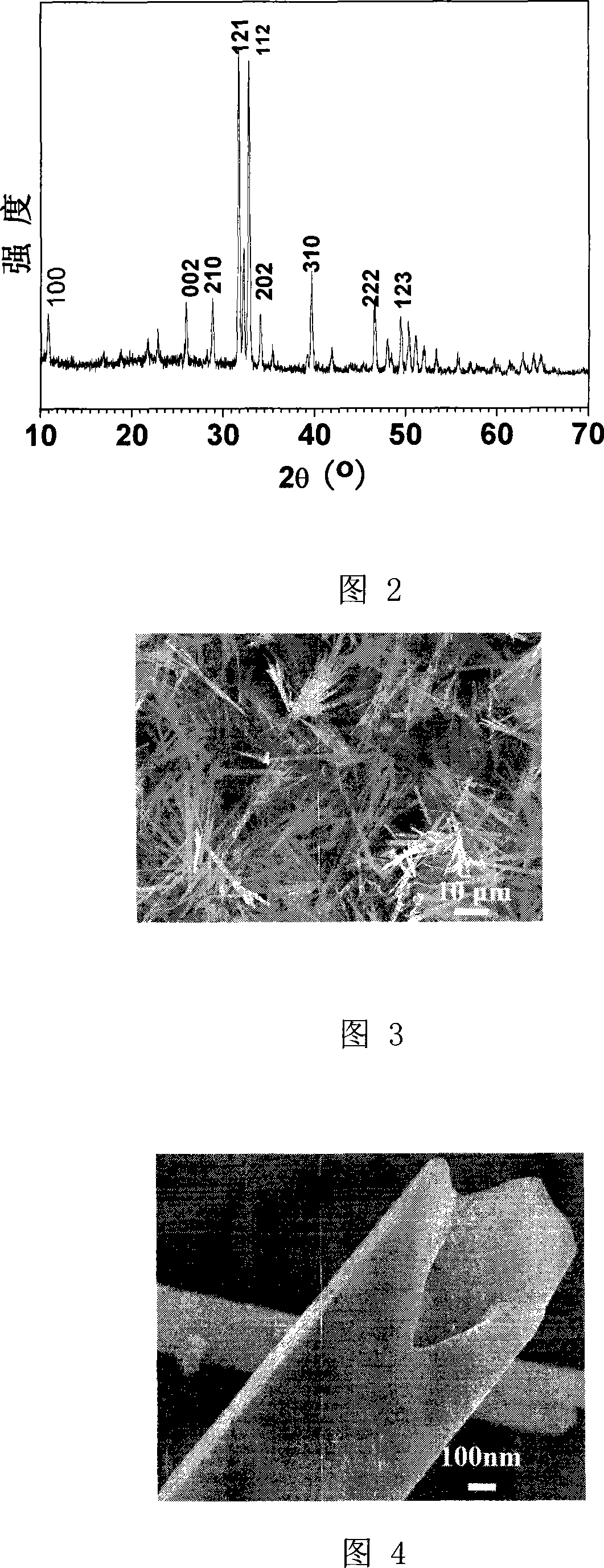

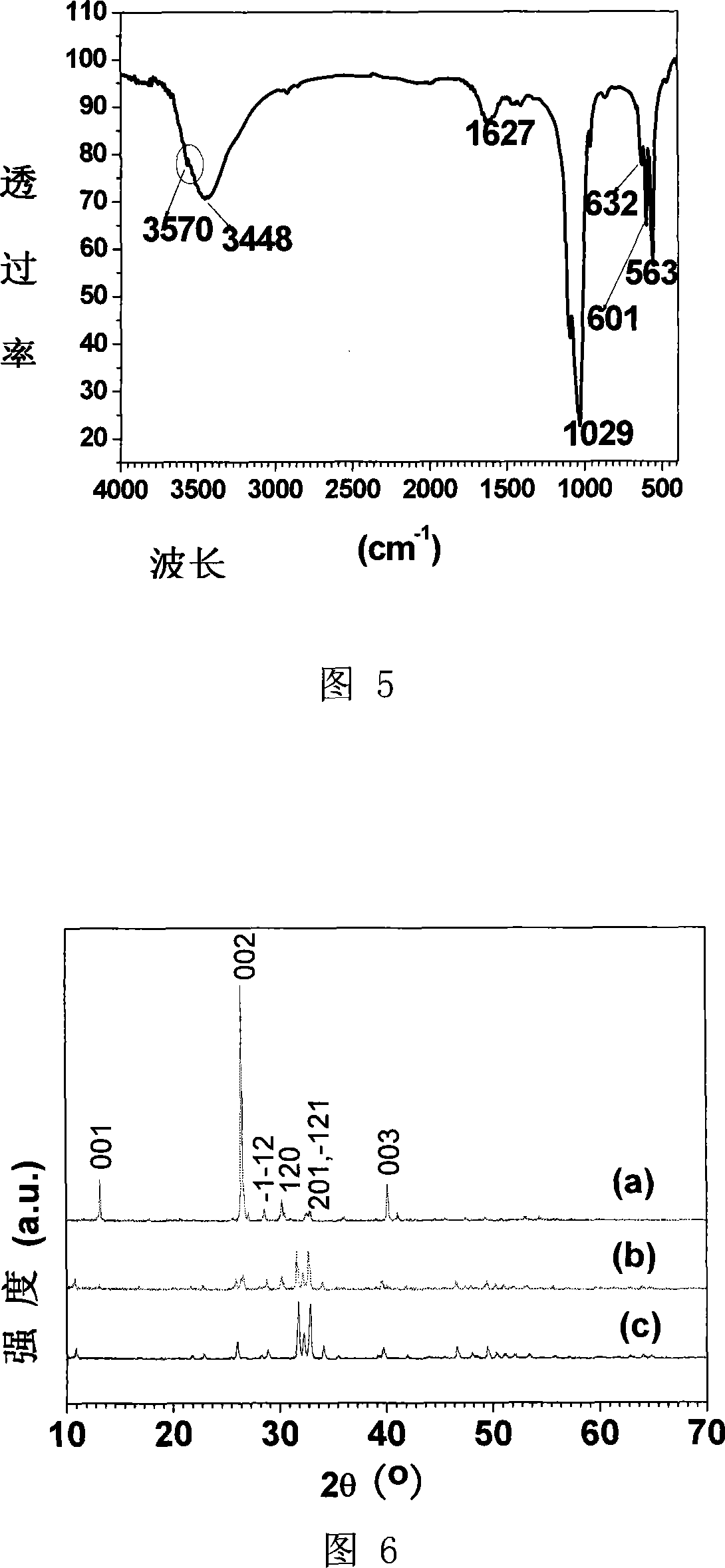

[0029] At room temperature, 0.110g CaCl 2 and 0.094g NaH 2 PO 4 Added to 5 mL of distilled water, followed by 10 mL of N,N-dimethylformamide to obtain a homogeneously dispersed suspension. The suspension was transferred to a 20mL reaction kettle and sealed. The reaction kettle was put into an oven and kept at 160° C. for 24 hours. After the reaction kettle was naturally cooled to room temperature, the product was taken out, and the product was separated by centrifugation. The separated product was washed twice with absolute ethanol and distilled water respectively, and dried under vacuum at 60°C. Fig. 2 is the X-ray diffraction spectrum of the hydroxyapatite microtube prepared in this example, no diffraction peaks of any impurities are found in the spectrum, indicating that the product is a single-phase hydroxyapatite microtube. Figures 3 and 4 are scanning electron micrographs of which the tubular structure can be clearly seen. Figure 5 is its infrared spectrum, 3570cm ...

Embodiment 2

[0031] At room temperature, 0.110g CaCl 2 and 0.094g NaH 2 PO 4 Added to 5 mL of distilled water, followed by 10 mL of N,N-dimethylformamide to obtain a homogeneously dispersed suspension. The suspension was transferred to a 20mL reaction kettle and sealed. The reaction kettle was put into an oven and kept at 160° C. for 12 hours. After the reaction kettle was naturally cooled to room temperature, the product was taken out, and the product was separated by centrifugation. The separated product was washed twice with absolute ethanol and distilled water respectively, and dried in vacuum at 60°C to obtain hydroxyapatite microtubes. Fig. 6c is the X-ray diffraction spectrum of the hydroxyapatite microtube prepared in this example, no diffraction peaks of any impurities are found in the spectrum, indicating that the obtained product is a single-phase hydroxyapatite microtube. The hydroxyapatite prepared in this example has a microtube structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com