Method for processing hexavalent chromium contained wastewater with ion exchange resin

A technology of ion exchange resin and hexavalent chromium, which is applied in the field of ion exchange resin to treat wastewater containing hexavalent chromium, which can solve the problems affecting the ion exchange performance of the resin, achieve clear product structure, realize governance and resource recovery, and be environmentally friendly in the preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

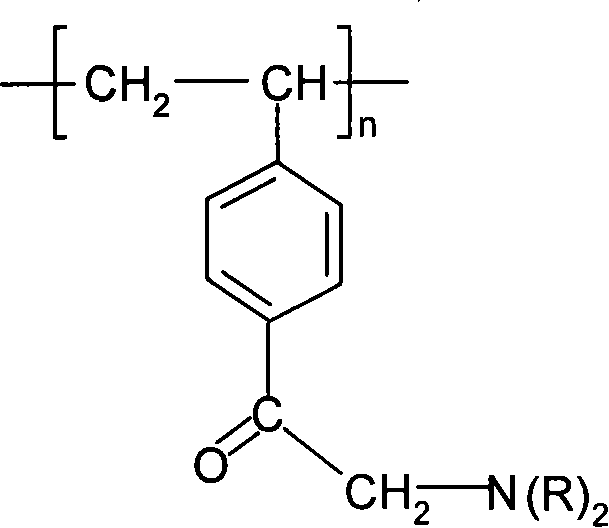

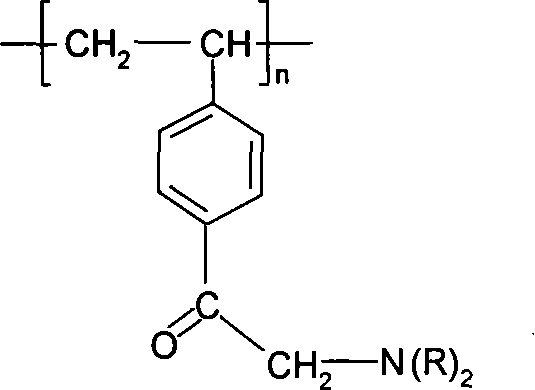

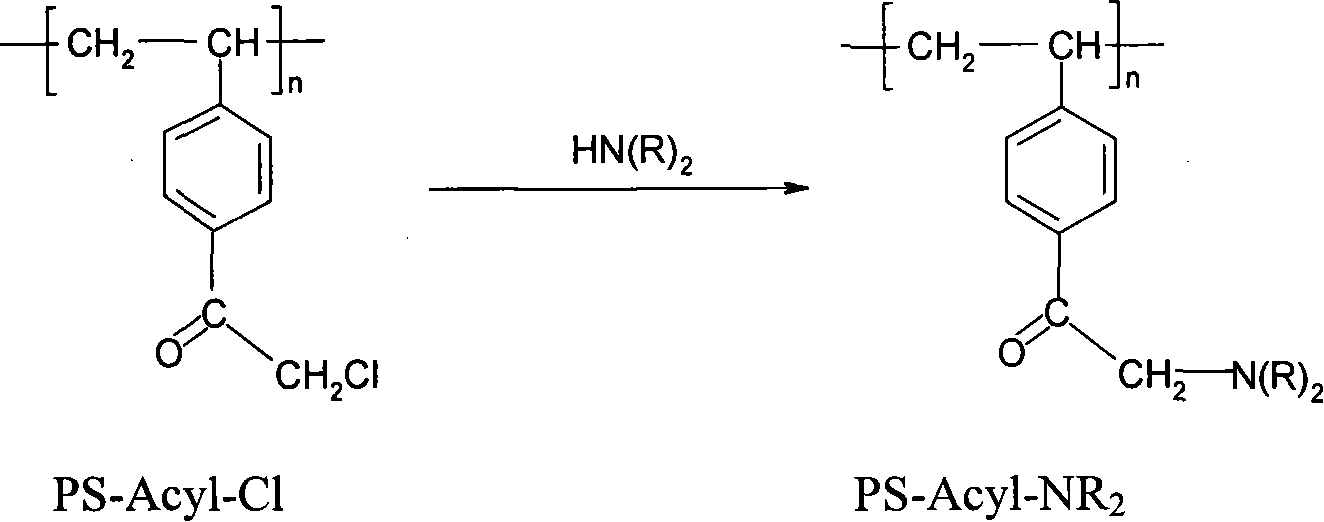

Method used

Image

Examples

Embodiment 1

[0017] 10mLPS-Acyl-NR 2 Installed in a glass column (Φ10×200mm).

[0018] Take 650mL of pretreated wastewater with a pH of 5 and a hexavalent chromium concentration of 3500mg / L, and pass through the resin bed at a flow rate of 6BV / h. Reuse, 565mL after effluent needs further treatment.

[0019] Using 500mL aqueous sodium hydroxide solution with a mass concentration of 5% as a desorbent, regenerate and recover hexavalent chromium at a flow rate of 3BV / h at 25°C, and the recovery rate reaches 96%.

Embodiment 2

[0021] 10mL PS-Acyl-NR 2 Installed in a glass column (Φ10×200mm).

[0022] Take 650mL of waste water with a pH of 5 and a hexavalent chromium concentration of 3500mg / L, and pass through the resin bed at a flow rate of 3BV / h. The last 565mL needs further processing.

[0023] Using 500mL aqueous potassium hydroxide solution with a mass concentration of 5% as a desorbent, regenerate and recover hexavalent chromium at a flow rate of 3BV / h at 25°C, and the recovery rate reaches 90%.

Embodiment 3

[0025] 10mL PS-Acyl-NR 2 Installed in a glass column (Φ10×200mm).

[0026] Take 650mL of waste water with a pH of 5 and a hexavalent chromium concentration of 3500mg / L, and pass through the resin bed at a flow rate of 3BV / h. The last 565mL needs further processing.

[0027] Using 700mL ammonia solution with a mass concentration of 10% as a desorbent, regenerate and recover hexavalent chromium at a flow rate of 12BV / h at 25°C, and the recovery rate reaches 89%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com