Device and method for cooking food without fire, electricity, vapor, oil and natural hot working

A thermal processing and food technology, applied in the field of food processing, can solve problems such as low thermal efficiency, human hazards, and environmental pollution, and achieve the effects of improving thermal efficiency, ensuring smooth exhaust, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

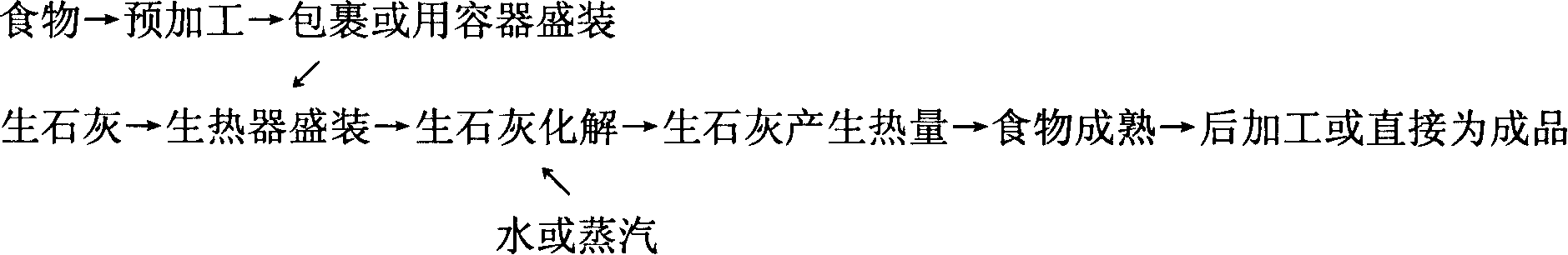

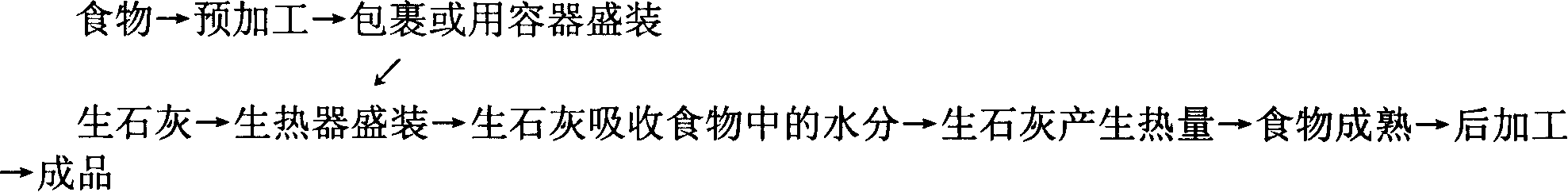

[0071] Utilize the heat source generated in the process of converting quicklime into slaked lime to process food, that is, put the food that needs to be cooked in quicklime, and then pour an appropriate amount of water or steam on the quicklime, and use the time when the quicklime meets water to turn into slaked lime. The heat produced cooks the food. It is also possible to wrap the food to be cooked with non-toxic materials, place it in quicklime, and use the characteristics of quicklime to absorb moisture and generate heat to dry and mature the food.

[0072] The quicklime is packed in a heat generator, which can be wrapped with an insulating layer outside the heat generator. Bury the food container in the quicklime of the heat generator. The heat generator and the food container should be heat-resistant containers, and can also be a pressure container.

[0073] More than two heat generators can be arranged, and each container is filled with insulating material to form a c...

Embodiment 2

[0084] First use a container smaller than a food container, such as a ceramic or casserole container to hold the food and its ingredients, then place it in the food container, then place the food container in quicklime or chaff, and water or pass through the quicklime Appropriate amount of steam, or ignite the rice bran, after a certain period of time, the food can be cooked. If the food container is a pressure type, the thermal efficiency is higher. The biggest advantage of this is that the food container served at the table will not be stained with lime or chaff ash.

Embodiment 3

[0086]Slaughter the chicken or fish, take out the viscera, add various ingredients to the belly of the chicken or fish, then wrap it with lard oil, lotus leaf or grass paper, take a certain amount of yellow mud or gypsum slurry, or both of them The mixed paste is wrapped in lotus leaf or grass paper, placed in quicklime, and then a small amount of water is poured into the quicklime or an appropriate amount of steam is introduced to process the common beggar chicken or beggar fish. The advantages of using gypsum instead of yellow mud to burn, bake, and smoke food are: gypsum contains calcium, which can transfer calcium beneficial to the human body into food, while yellow mud has no such effect; However, using gypsum can overcome this shortcoming; using yellow mud as a wrapping material will easily cause the plaster to wave when eating, but gypsum wrapping does not have this shortcoming; the food wrapped with mud is gray because of its appearance. It is difficult to enter the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com