Preparation method of tin oxide electrode for glass electric melting furnace

A technology of tin dioxide and glass electricity, applied in the directions of tin oxide, electric furnace, furnace, etc., can solve the problems of poor electrical conductivity of electrodes, difference in service life of electrodes, etc., to achieve improved service life, simple method and operation, and improved electrical performance and physical and chemical properties. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

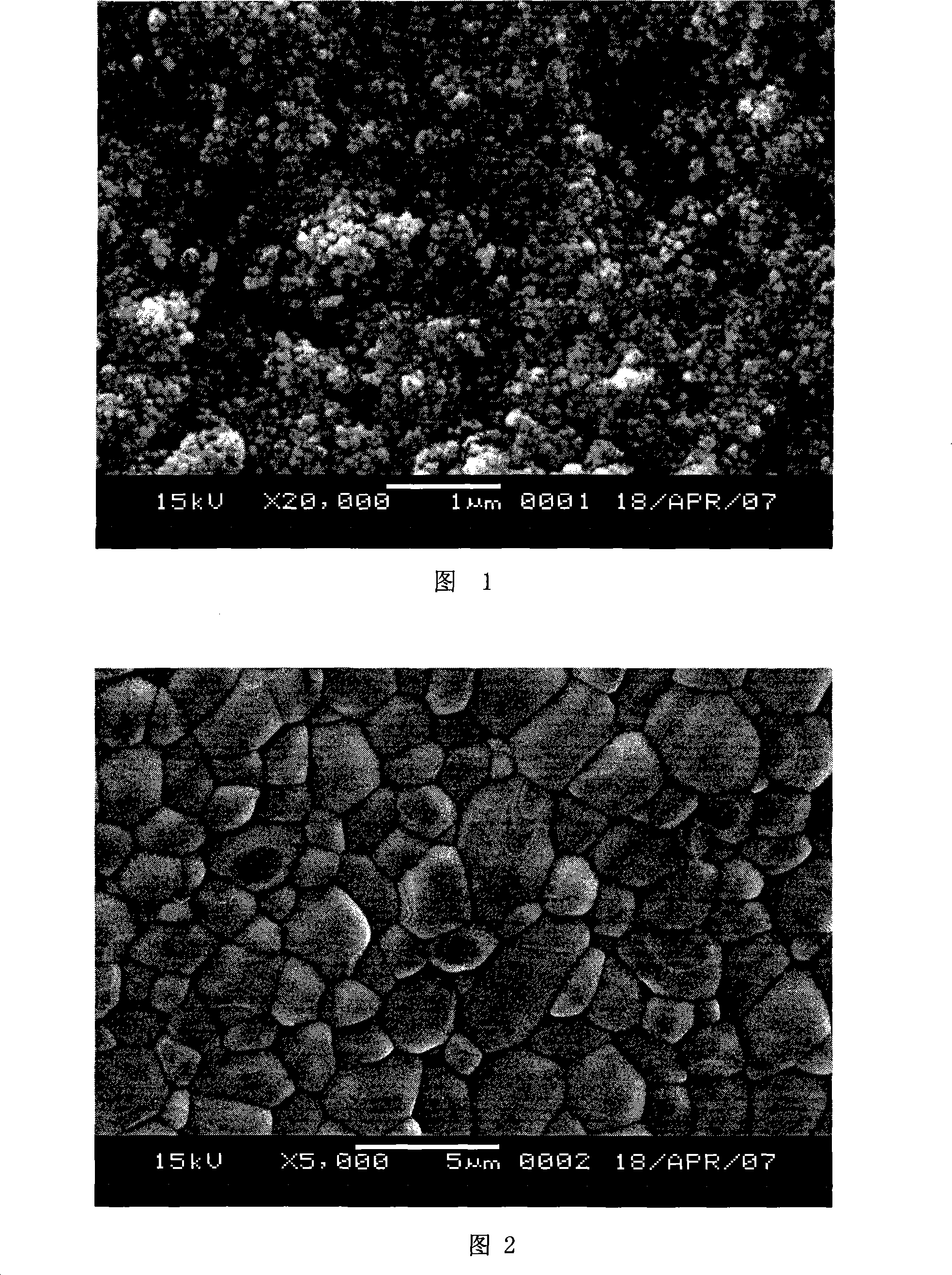

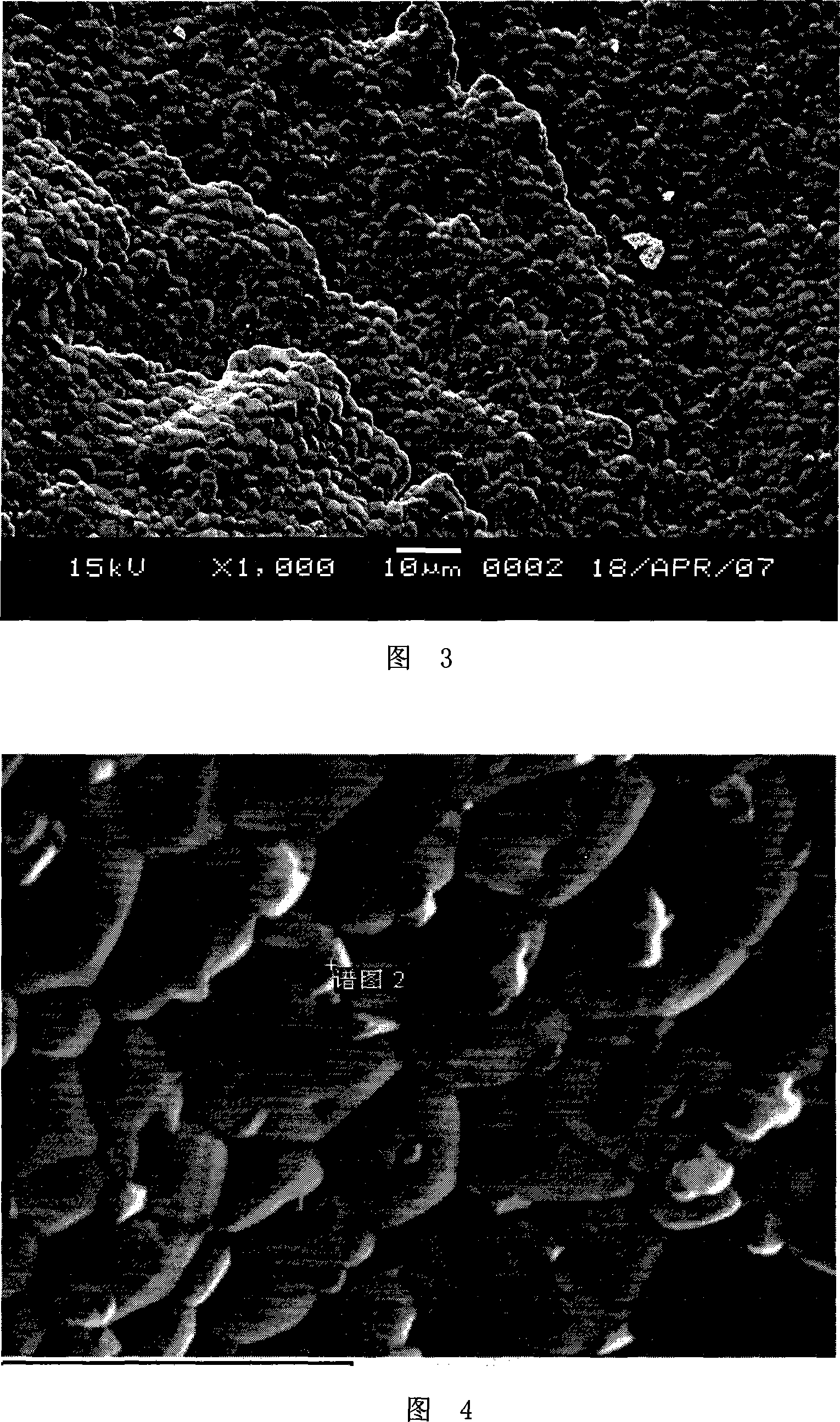

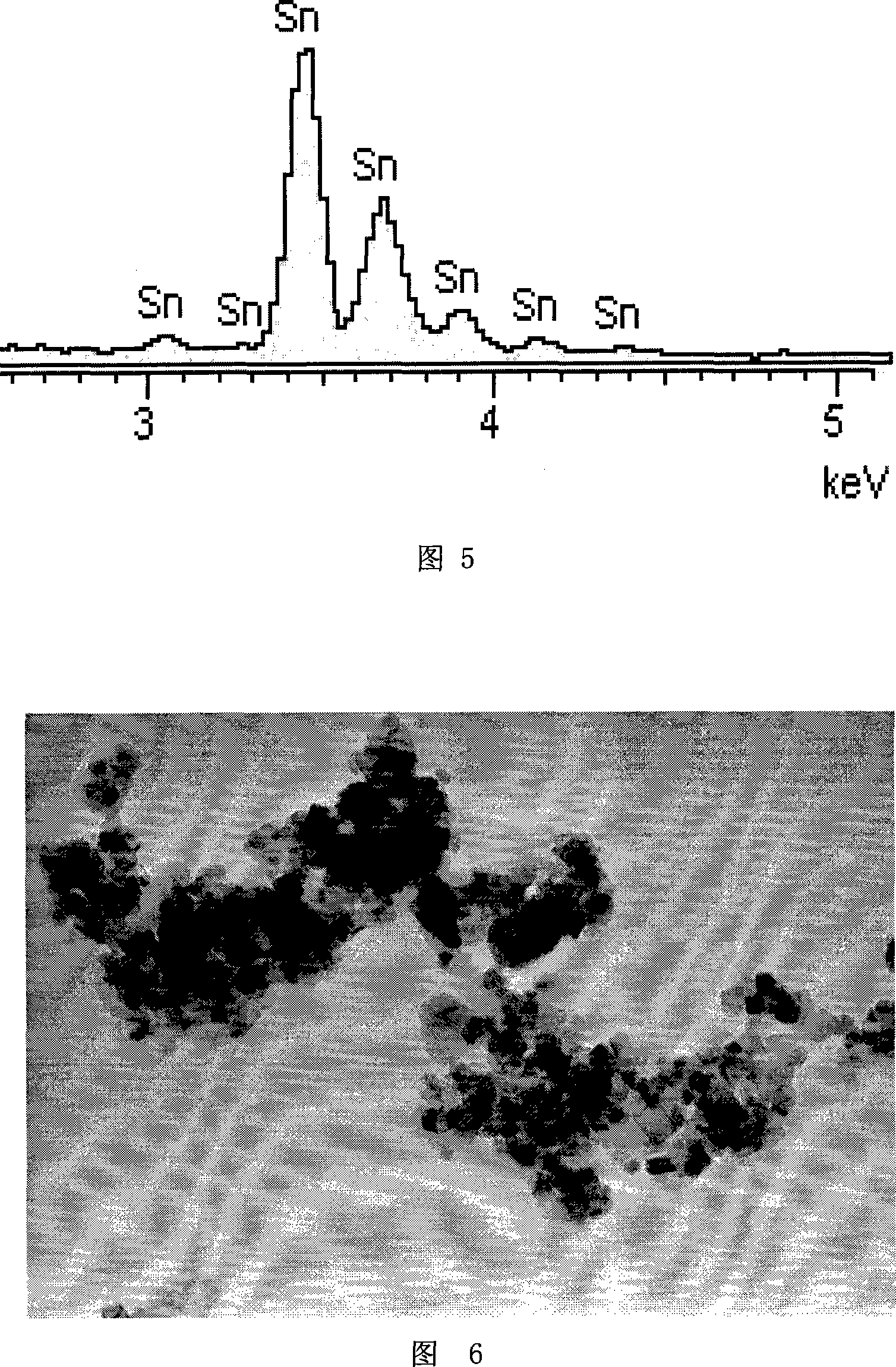

[0018] Analytical pure antimony trichloride (SbCl 3 ) and tin tetrachloride (SnCl 4 ) as raw material, according to Sb 2 o 3 with SnO 2 Weigh and dissolve with a mass ratio of 1:99, add deionized water to a certain volume, and slowly add a certain concentration of ammonia water to the mixed solution under magnetic stirring to carry out coprecipitation reaction, wash the precipitate with deionized water until it is washed with 0.1 mol / L AgNO 3 Check for Cl - exists, and then washed three times with absolute ethanol to obtain the precursor, dried, ground, and calcined at 650°C for 2 hours to obtain Sb 2 o 3 doped ultrafine SnO 2 powder; the prepared Sb 2 o 3 doped ultrafine SnO 2 The powder is initially pressed, dried, and sintered at 1350° C. to obtain the tin dioxide electrode for glass electric melting furnace of the present invention.

Embodiment 2

[0020] Analytical pure antimony trichloride (SbCl 3 ) and tin tetrachloride (SnCl 4 ) as raw material, according to Sb 2 o 3 with SnO 2 The mass ratio is 1.5:98.5, weigh and dissolve, add deionized water to a certain volume, under magnetic stirring, slowly add a certain concentration of ammonia water to the mixed solution for co-precipitation reaction, wash the precipitate with deionized water until it is washed with 0.1 mol / L AgNO 3 Check for Cl - exists, and then washed three times with absolute ethanol to obtain the precursor, dried, ground, and calcined at 560°C for 2 hours to obtain Sb 2 o 3 doped ultrafine SnO 2 powder; the prepared Sb 2 o 3 doped ultrafine SnO 2 The powder is initially pressed, dried, and sintered at 1400° C. to obtain the tin dioxide electrode for glass electric melting furnace of the present invention.

Embodiment 3

[0022] To analyze pure copper chloride (CuCl 2 ) and tin tetrachloride (SnCl 4 ) as raw material, according to CuO and SnO 2 Weigh and dissolve with a mass ratio of 1:99, add deionized water to a certain volume, and slowly add a certain concentration of ammonia water to the mixed solution under magnetic stirring to carry out coprecipitation reaction, wash the precipitate with deionized water until it is washed with 0.1 mol / L AgNO 3 Check for Cl - exist, and then washed three times with absolute ethanol to obtain the precursor, dried, ground, and calcined at 580 ° C for 2 h to obtain CuO-doped ultrafine SnO 2 Powder; CuO-doped ultrafine SnO 2 The powder is initially pressed, dried, and sintered at 1300° C. to obtain the tin dioxide electrode for glass electric melting furnace of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com