Heat treatment-dehydration-fertilizer making method for town sewage and sludge

A technology for urban sewage and dewatered sludge, which is used in sewage/sludge fertilizer, dewatering/drying/concentrating sludge treatment, sludge treatment through temperature control, etc. Large energy consumption and other problems, to achieve the effect of shortening waste liquid treatment time, reducing costs, and reducing heat treatment temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

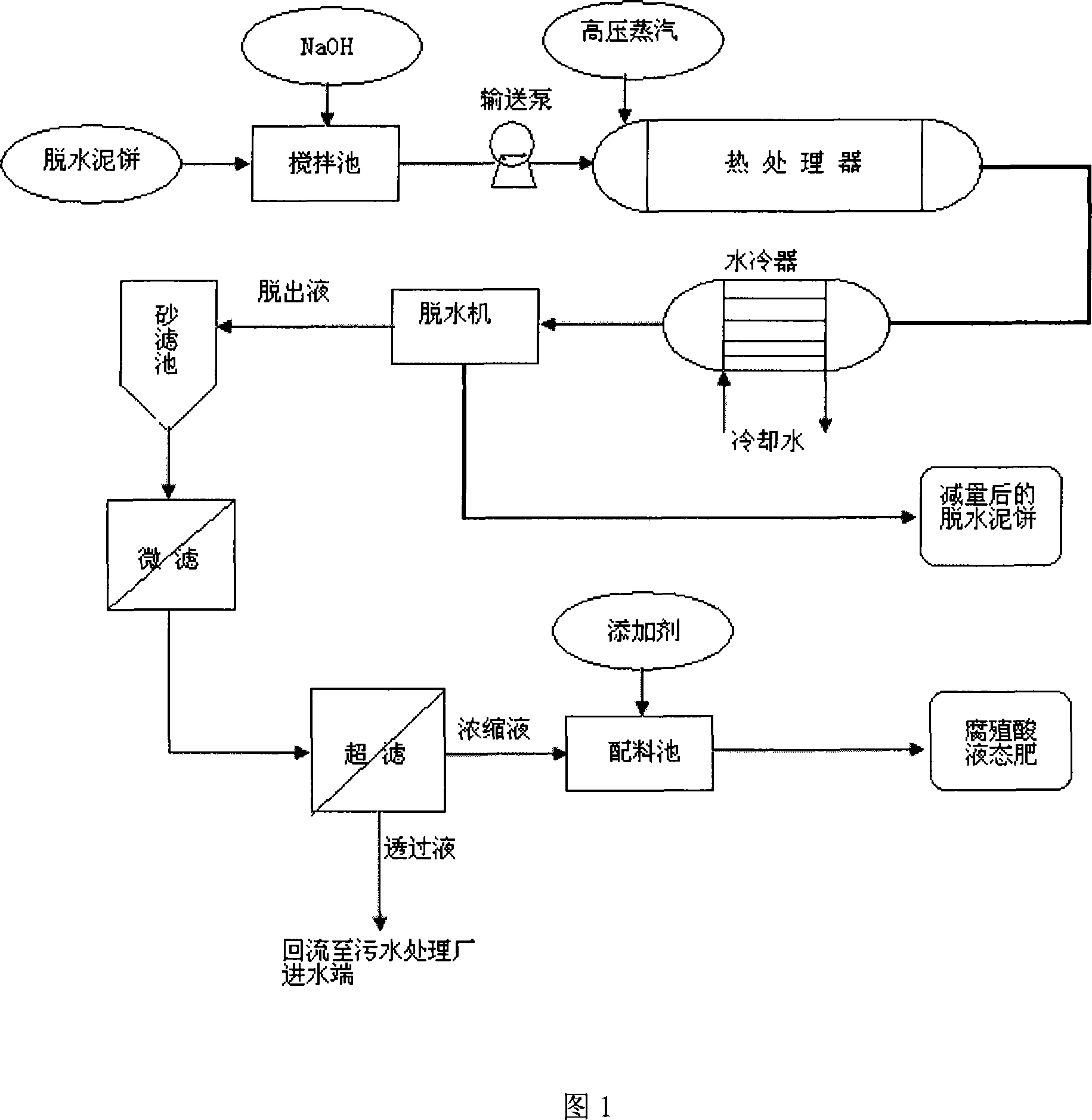

Image

Examples

Embodiment 1

[0031] The moisture content of the dehydrated cake produced by an urban sewage treatment plant is 81%, and the organic matter content in the dry solid is 74%.

[0032] Add 0.16wt% sodium hydroxide to the dewatered cake, then use the screw pump to transport it to the horizontal screw heat processor, feed it with high-pressure steam (250 ° C, 4 MPa) to heat it to 140 ° C, and the residence time is 40min; after the sludge reacts, it enters the water cooler, and after cooling, it is mechanically dehydrated. As a result of the reaction, compared with before treatment, the dry solid mass decreased by 40%, and the moisture content of the dewatered cake was 47%; the chemical oxygen demand (COD) in the waste liquid was 103.0g / L, and the humic acid content was 31.0g / L. After full filtration and purification, the content of humic acid is 3.1wt%, the content of heavy metals is Cd≤0.01wt%, As≤0.002wt%, Pb≤0.002wt%, which is in line with the "Guidelines for the Use of Fertilizers" of the Mi...

Embodiment 2

[0034] The moisture content of the dehydrated cake produced by an urban sewage treatment plant is 80%, and the organic matter content in the dry solid is 61%.

[0035] Add 0.08wt% sodium hydroxide to the dewatered cake, then use the screw pump to transport it to the horizontal screw heat processor, feed it into high-pressure steam (250 ° C, 4 MPa) to heat it to 120 ° C, and the residence time is 100min; after the sludge reacts, it enters the water cooler, and after cooling, it is mechanically dehydrated. As a result of the reaction, compared with before treatment, the dry solid mass decreased by 35%, and the moisture content of the dewatered cake was 56%; the COD in the waste liquid was 99.7g / L, and the humic acid content was 22.2g / L, which was purified and concentrated by 2 times through full filtration Humic acid content is 4.4wt%, heavy metal content Cd≤0.01wt%, As≤0.002wt%, Pb≤0.002wt%, in line with the Ministry of Agriculture's "Fertilizer Use Guidelines"; ultrafiltration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com