Method for synthesizing polycarboxylic acid series cement water reducer accelerated by microwave

A technology for synthesizing polycarboxylic acid and water reducing agent, which is applied in the field of synthesizing polycarboxylic acid cement water reducing agent, can solve problems such as unstable copolymer performance, and achieve the effects of reducing energy consumption, reducing pollution, and shortening reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

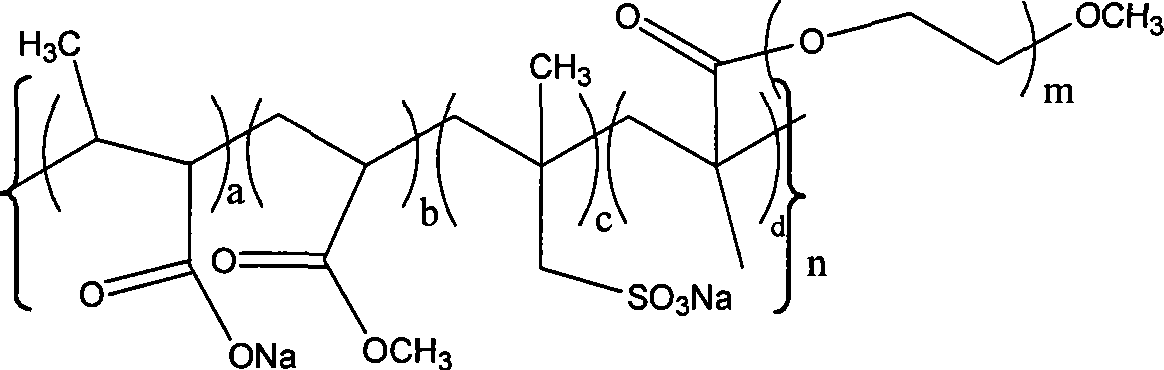

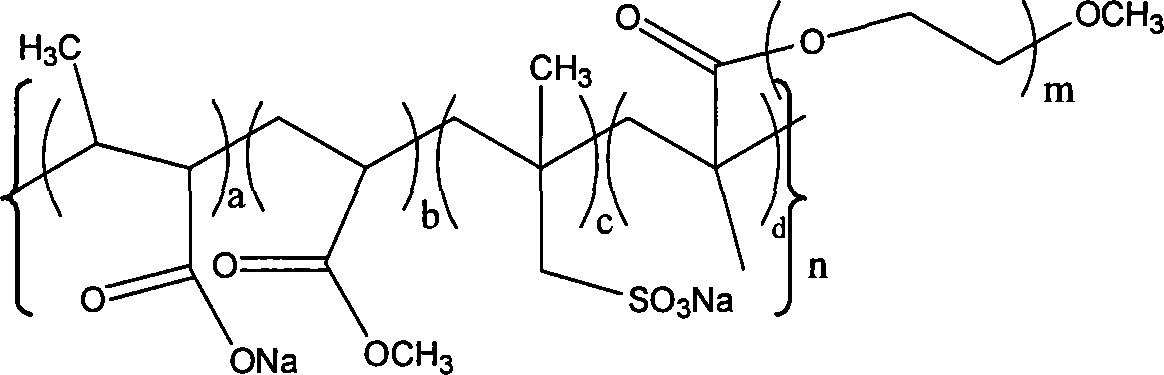

[0018] Example 1: Microwave-promoted synthesis of polycarboxylate water reducer

[0019] With comparative example conditions, add polyethylene glycol (20) monomethyl ether methacrylate 55.6g (0.05mol), methyl acrylate 12.9g (0.15mol), sodium methacrylate sulfonate in the reactor with stirring 15.9g (0.1mol), methacrylic acid 60.2g (0.7mol) and 145g water, stir well. A solution of ammonium persulfate (0.87 g in 10 g of water) was then added thereto with stirring. The reactor was placed in a microwave reactor, and the above-mentioned reaction mixture was irradiated with 1000w microwave to rapidly raise the temperature to 90°C. Then set the microwave power to 1000w and the reaction temperature to 90°C, and react under stirring for 5 minutes to obtain a colorless, transparent and uniform solution. The existence of double bonds cannot be detected by iodometric method. Continue aging for 1 to 2 minutes under the same microwave radiation reaction conditions. The aqueous sodium hydr...

Embodiment 2

[0021] Embodiment 2: Microwave promotes the synthesis of polycarboxylate water reducer

[0022] Add polyethylene glycol (23) monomethyl ether methacrylate 111.2g (0.1mol), methyl acrylate 8.6g (0.1mol), sodium methacrylate sulfonate 23.9g (0.15mol) in the stirred reactor ), methacrylic acid 55.9g (0.65mol) and 200g water, stir well. A solution of ammonium persulfate (1.4 g in 10 g of water) was then added thereto with stirring. The reactor was placed in a microwave reactor, and the above-mentioned reaction mixture was irradiated with 1000w microwave to rapidly raise the temperature to 80°C. Then set the microwave power to 800w and the reaction temperature to 80°C, and react under stirring for 6 minutes to obtain a colorless, transparent and uniform solution. The presence of double bonds cannot be detected by the iodometric method. The aqueous sodium hydroxide solution is adjusted to pH=7~8 to obtain the product.

[0023] Referring to the method for determining the solid con...

Embodiment 3

[0024] Embodiment 3: Microwave promotes the synthesis of polycarboxylate water reducer

[0025] In the stirred reactor, add polyethylene glycol (18) monomethyl ether methacrylate 167g (0.15mol), methyl acrylate 17g (0.2mol), sodium methacrylate sulfonate 8g (0.05mol), methyl Acrylic acid 52g (0.6mol) and 250g water, stir well. A solution of ammonium persulfate (2.2 g in 10 g of water) was then added thereto with stirring. The reactor was placed in a microwave reactor, and the above-mentioned reaction mixture was irradiated with 1000w microwave to rapidly raise the temperature to 70°C. Then set the microwave power to 600w and the reaction temperature to 70°C, and react under stirring for 7 minutes to obtain a colorless, transparent and uniform solution. The presence of double bonds cannot be detected by the iodometric method. Continue aging for 1 to 2 minutes under the same microwave radiation reaction conditions. The aqueous sodium hydroxide solution is adjusted to pH=7~8 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com