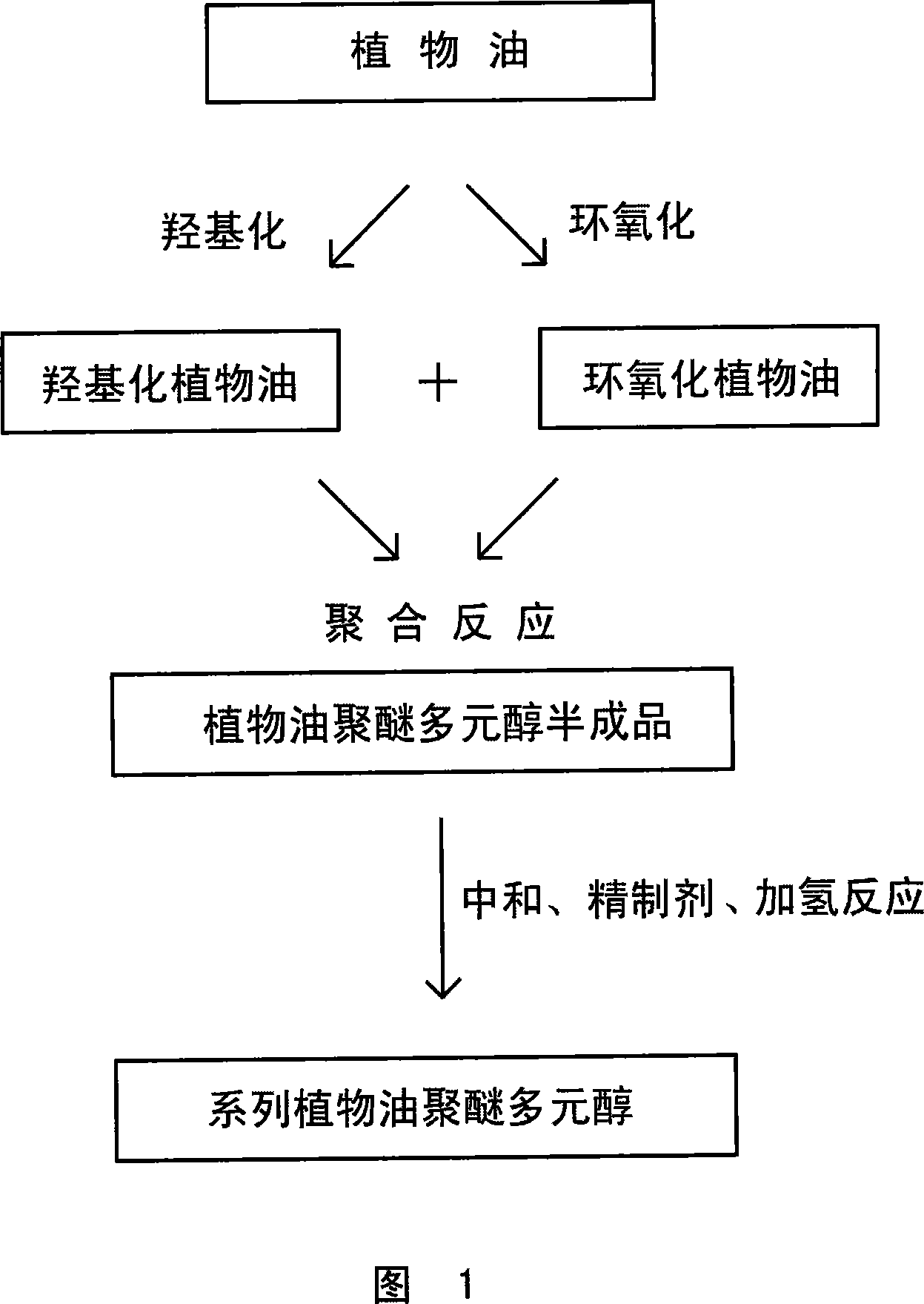

Method for preparing polyether polyol from plant oil

A polyether polyol and vegetable oil technology, applied in the field of polymer polymerization, can solve the problems that have not been found and reported, and achieve the effect of cheap and easy-to-obtain raw materials, narrow molecular weight distribution, and strong functionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

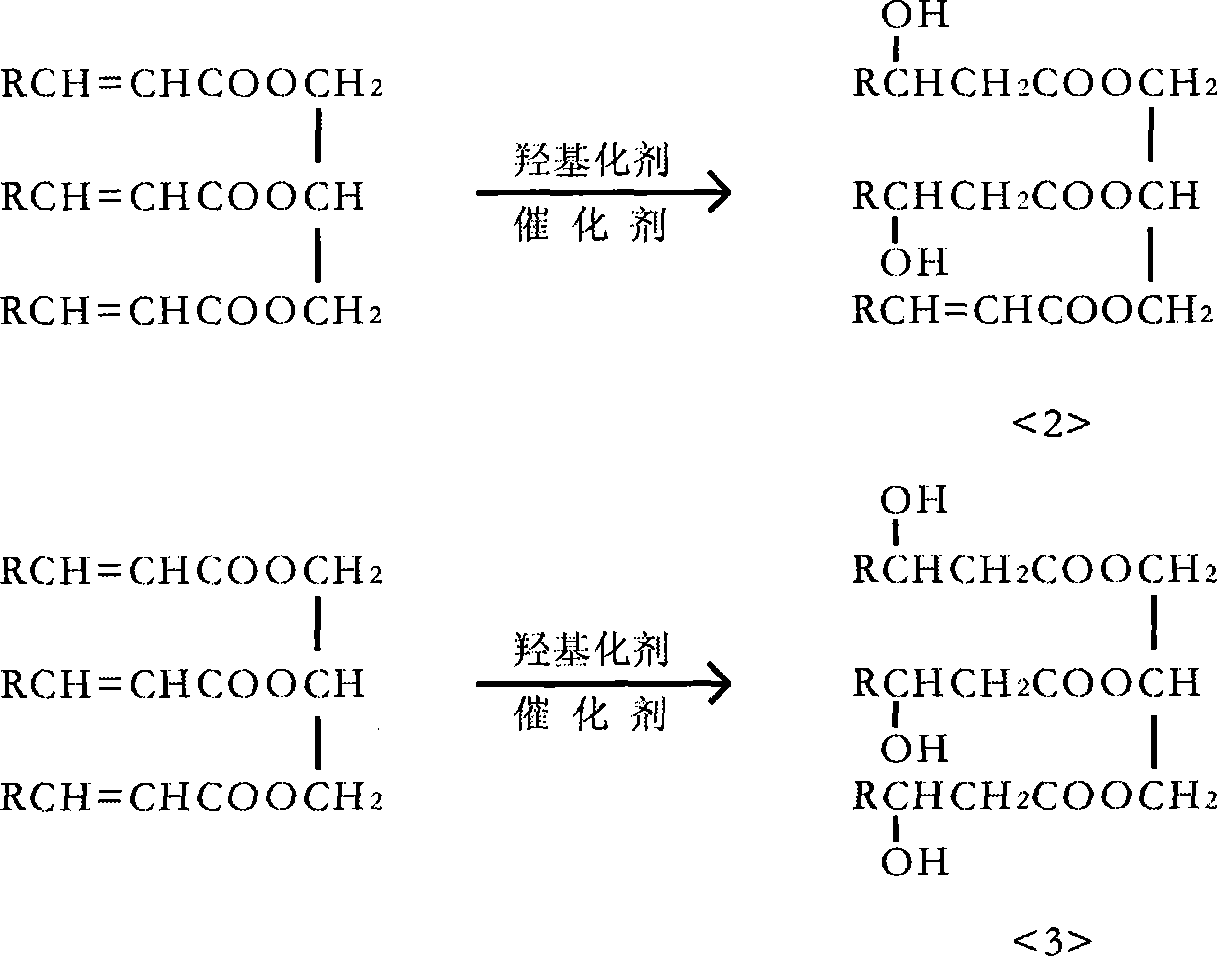

Method used

Image

Examples

Embodiment 1

[0057] Embodiment 1 (embodiment 1-4 is step A) product)

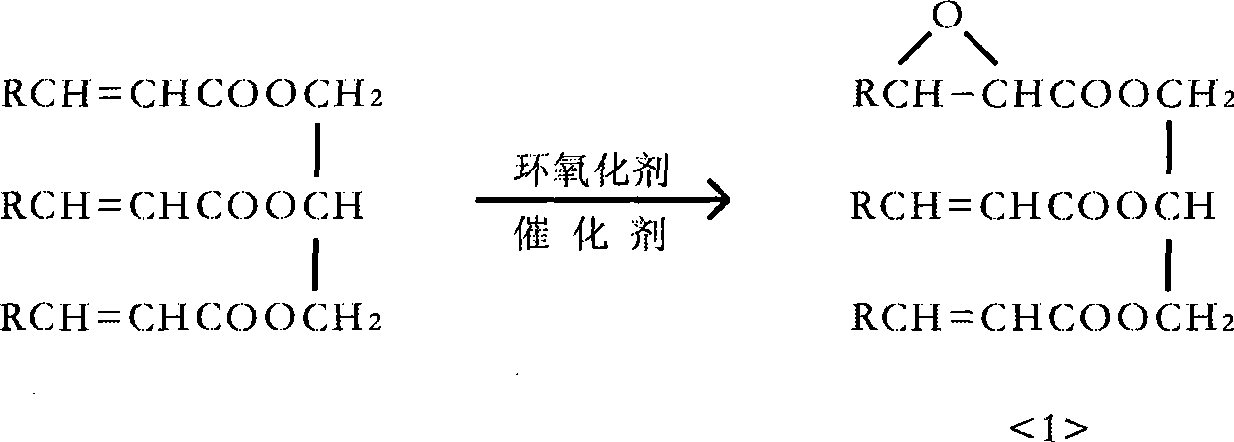

[0058] Add 500g of soybean oil and 20g of 80% formic acid into a 1L glass kettle, stir for 10 minutes, add 50g of 30% hydrogen peroxide dropwise, the molar ratio of hydrogen peroxide to soybean oil is 0.80, and the molar ratio of catalyst carboxylic acid to soybean oil It was 0.64, reacted at 40-45°C for 5 hours, allowed to stand and separated into layers to separate the acid water, washed twice, decompressed and vacuumed, and the moisture was less than 0.10%, to obtain epoxidized vegetable oil, and the epoxy value of the product was detected to be 2.7% , this product is ring A.

Embodiment 2

[0060] 500g of rapeseed oil will be added in a 1L glass kettle, with 30g of 80% formic acid and 10g of 50% sulfuric acid, stirred for 10 minutes, and 52g of 30% hydrogen peroxide is added dropwise. The molar ratio is 0.85, the molar ratio of catalyst carboxylic acid to rapeseed oil is 0.95, react at 50-60°C for 6 hours, stand and separate the acid water by layering, wash twice, decompress and vacuum, and the moisture is less than 0.10%, to obtain Epoxidized vegetable oil, obtains epoxidized vegetable oil, detects that the epoxy value of product is 3.5%, and this product is ring B.

Embodiment 3

[0062] Add 500g of corn oil to a 1L glass kettle, use 30g of 80% acetic acid, 10g of 50% sulfuric acid, stir for 10 minutes, add 45g of 30% hydrogen peroxide dropwise, the molar ratio of hydrogen peroxide to corn oil 0.72, the molar ratio of catalyst carboxylic acid to corn oil is 0.73, react at 45-55°C for 5 hours, stand and separate the acid water, wash twice, decompress and vacuum, the moisture is less than 0.10%, and the epoxidized Vegetable oil, the epoxy value of product detected is 3.1%, and this product is ring C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com