Phosphoric acid solution exchanging method and control program in semiconductor integrated circuit production

A technology of integrated circuits and control programs, applied in semiconductor/solid-state device manufacturing, electrical program control, circuits, etc., can solve the problems of slow silicon oxide film corrosion rate, reduced device product quality, and reduced pass rate, etc., and achieves a simple structure. , Improve the quality and pass rate, the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

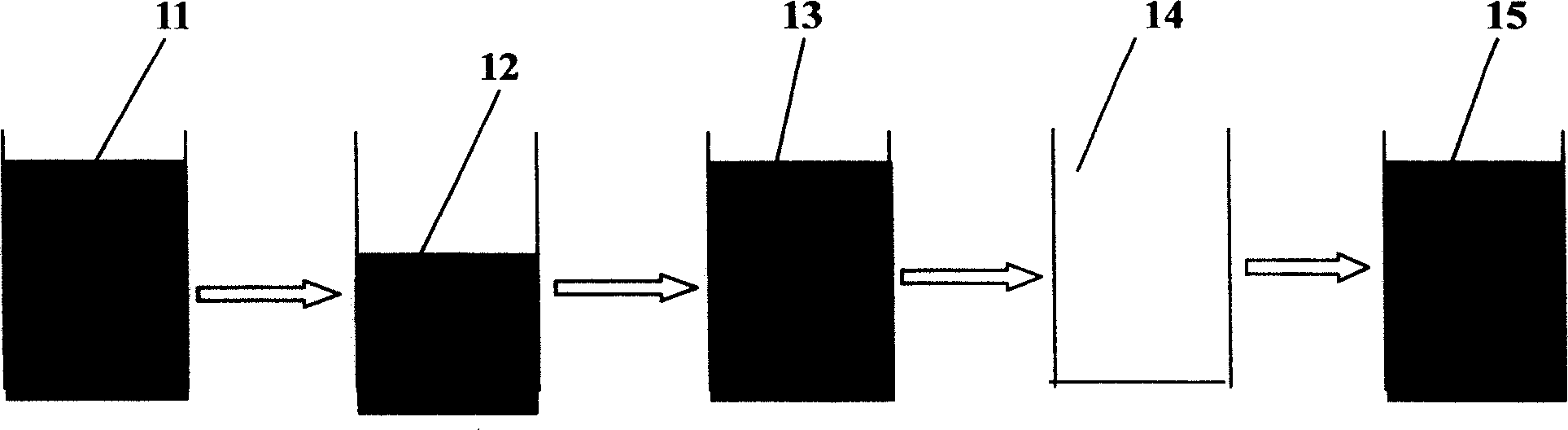

[0017] Such as figure 1 As shown, the sequential process of the liquid medicine exchange method of the present invention includes a full tank liquid 11, a partial liquid liquid exchange 12, a partial new liquid supplement 13, a full liquid liquid exchange 14, and a full tank new liquid 15 replenishment.

Embodiment approach 2

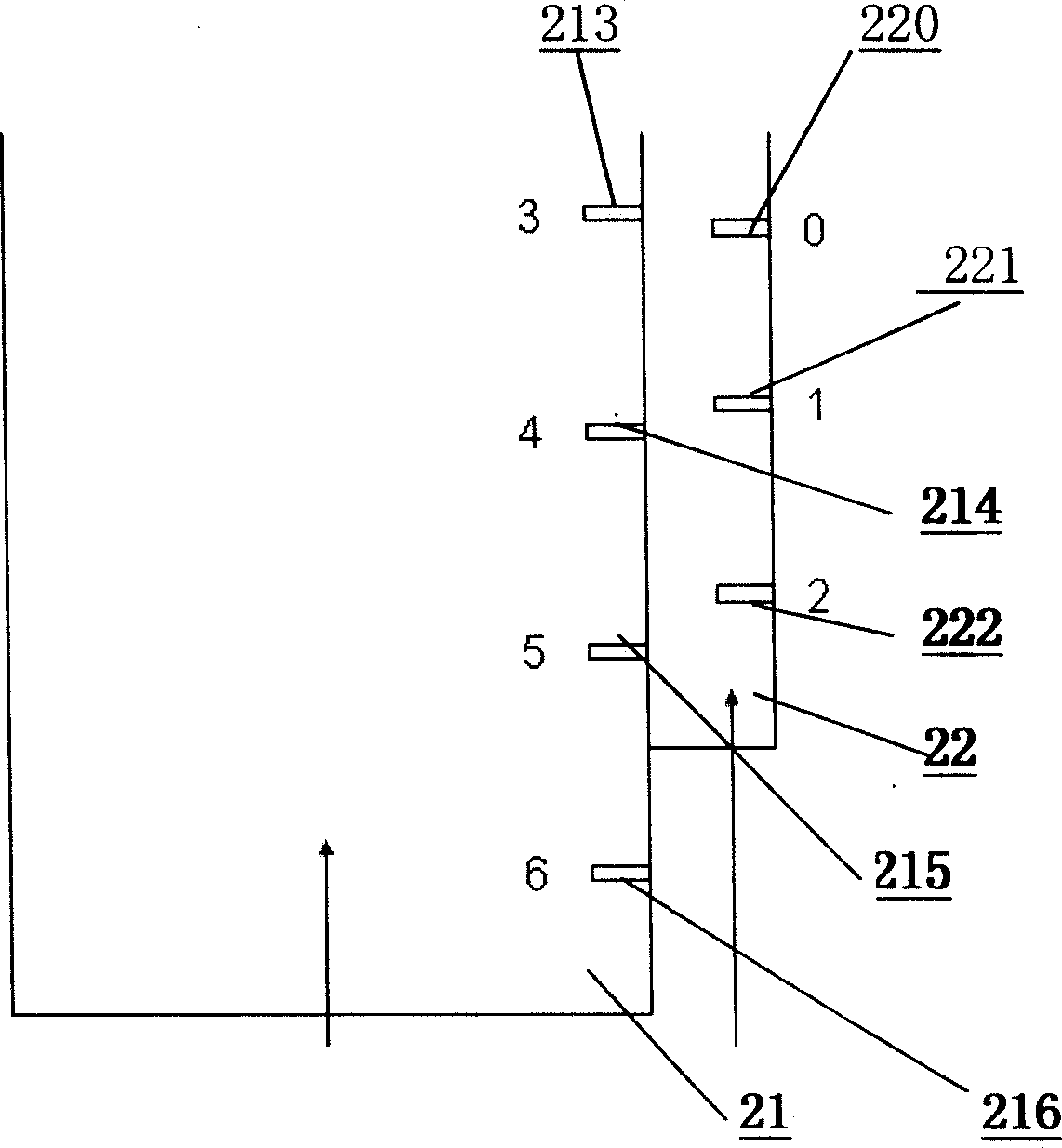

[0019] For example figure 2 The description of the main parameters of the control program in the schematic structural diagram of the liquid medicine exchange device of the present invention is shown. The main parameters include the working cycle count of the full amount of liquid medicine exchange and the exchange state of the liquid medicine to discharge the residual liquid, which are respectively explained as follows.

[0020] The working cycle count (Life count) of the full amount of liquid medicine exchange is:

[0021] The first round means that part of the liquid medicine is not exchanged, and only one full tank of liquid medicine is exchanged, that is, every time the liquid medicine is exchanged, the liquid medicine of the whole tank is exchanged;

[0022] The second time means performing a partial liquid exchange and a full tank liquid exchange. That is, after each part of the drug solution exchange frequency is N batches of products, after a part of the drug soluti...

Embodiment

[0036] In the above-mentioned embodiments, at a temperature of 160 degrees, the concentration of the phosphoric acid solution used is 85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com