Method for producing porcelain granule light weight aggregate with sewage sludge

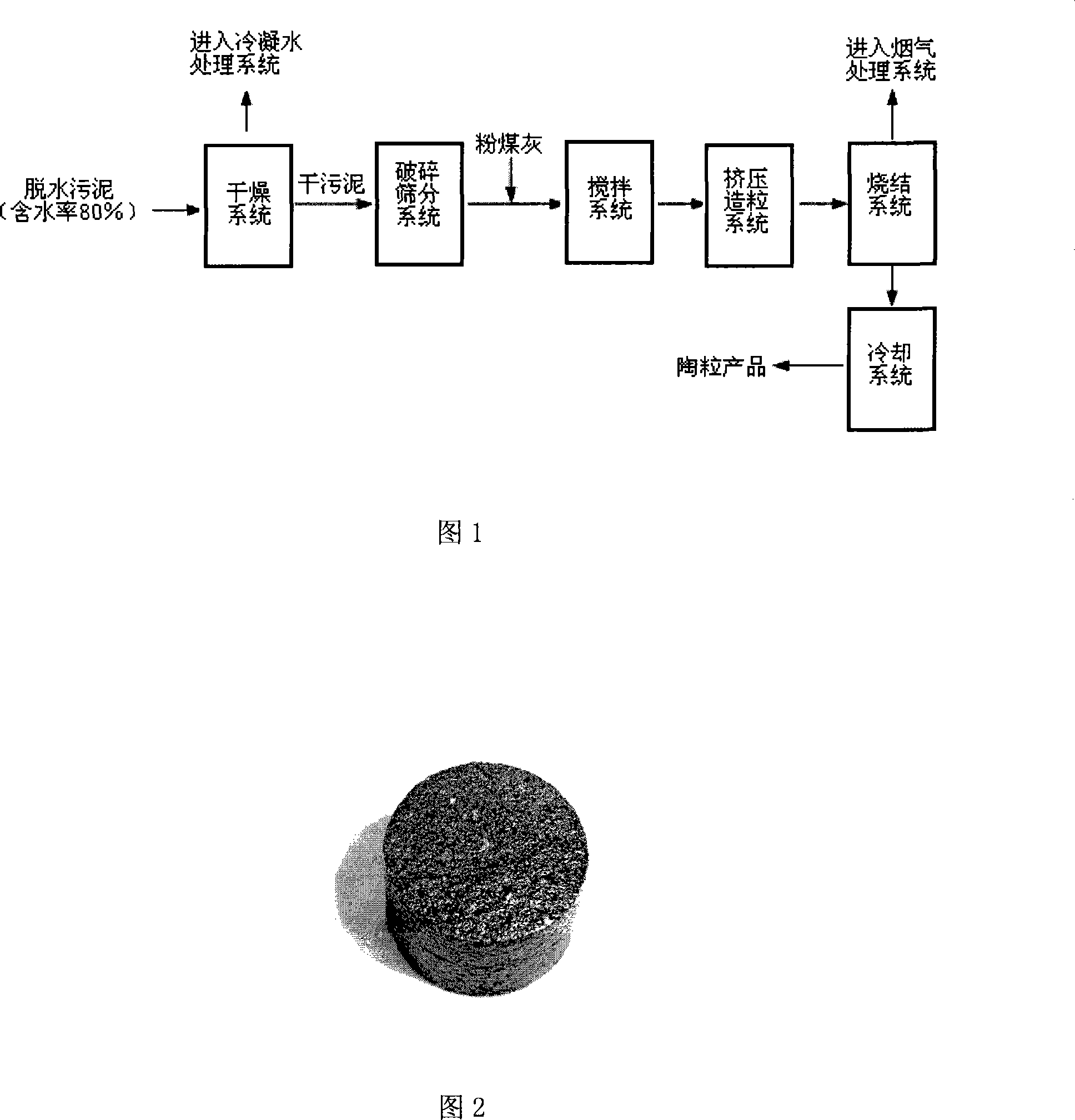

A lightweight aggregate and ceramsite technology, applied in the production of ceramic materials, dehydration/drying/concentrated sludge treatment, application, etc., can solve the problems of high sintering temperature and low sludge mixing ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In this embodiment, the amount of fly ash added accounts for 18% of the dry sludge mass, and the sintering temperature is 1080°C. The preparation method steps are as follows:

[0028] a. Firstly, heat-dry the dewatered sludge, and use a paddle dryer to dry at 180°C for 2 hours to obtain dry sludge with a moisture content of <10%;

[0029] b. The universal pulverizer crushes and sieves through a 45mm sieve;

[0030] c. Add fly ash with 18% dry sludge mass according to the raw material ratio of the process, and stir with a cement slurry mixer for 5 minutes, and mix evenly;

[0031] d, 8 MPa powder extrusion molding machine to obtain lightweight aggregate ceramsite blank;

[0032] e. Preheat at 350°C for 20 minutes. The purpose of preheating is mainly to reduce the content of organic matter in the billet and avoid cracking of the billet during sintering; sinter at 1080°C for 30 minutes;

[0033] f, the product is obtained after natural cooling.

Embodiment 2

[0035] In this embodiment, the amount of fly ash added accounts for 25% of the dry sludge mass, and the sintering temperature is 1100°C. The preparation method steps are as follows:

[0036] a. Firstly, heat-dry the dewatered sludge, and use a paddle dryer to dry at 180°C for 2 hours to obtain dry sludge with a moisture content of <10%;

[0037] b. The universal pulverizer crushes and sieves through a 45mm sieve;

[0038] c. Add fly ash with 25% dry sludge mass according to the raw material ratio of the process, and stir with a cement slurry mixer for 5 minutes to mix evenly;

[0039] d, 8 MPa powder extrusion molding machine to obtain lightweight aggregate ceramsite blank;

[0040] e. Preheat at 350°C for 20 minutes. The purpose of preheating is mainly to reduce the content of organic matter in the billet and avoid cracking of the billet during sintering; sinter at 1100°C for 30 minutes;

[0041] f, the product is obtained after natural cooling.

Embodiment 3

[0043] In this embodiment, the amount of fly ash added accounts for 20% of the dry sludge mass, and the sintering temperature is 1090°C. The preparation method steps are as follows:

[0044] a. Firstly, heat-dry the dewatered sludge, and use a paddle dryer to dry at 180°C for 2 hours to obtain dry sludge with a moisture content of <10%;

[0045] b. The universal pulverizer crushes and sieves through a 45mm sieve;

[0046] c. Add fly ash with 20% dry sludge mass according to the raw material ratio of the process, and stir with a cement slurry mixer for 5 minutes to mix evenly;

[0047] d, 8 MPa powder extrusion molding machine to obtain lightweight aggregate ceramsite blank;

[0048] e. Preheat at 350°C for 20 minutes. The purpose of preheating is mainly to reduce the content of organic matter in the blank and avoid cracking of the blank during sintering; sinter at 1090°C for 30 minutes;

[0049] f, the product is obtained after natural cooling.

[0050] Fig. 2 Schematic di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com