Natural gas adjusting cardboard box method for apples fresh-keeping

A fresh-keeping method and natural gas technology, which is applied in the fields of fruit and vegetable fresh-keeping, food preservation, and protection of fruits/vegetables with a coating protective layer, which can solve the problems that fresh-keeping storage methods are difficult to guarantee the original quality, and achieve low cost and prolong the fresh-keeping period , good gloss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

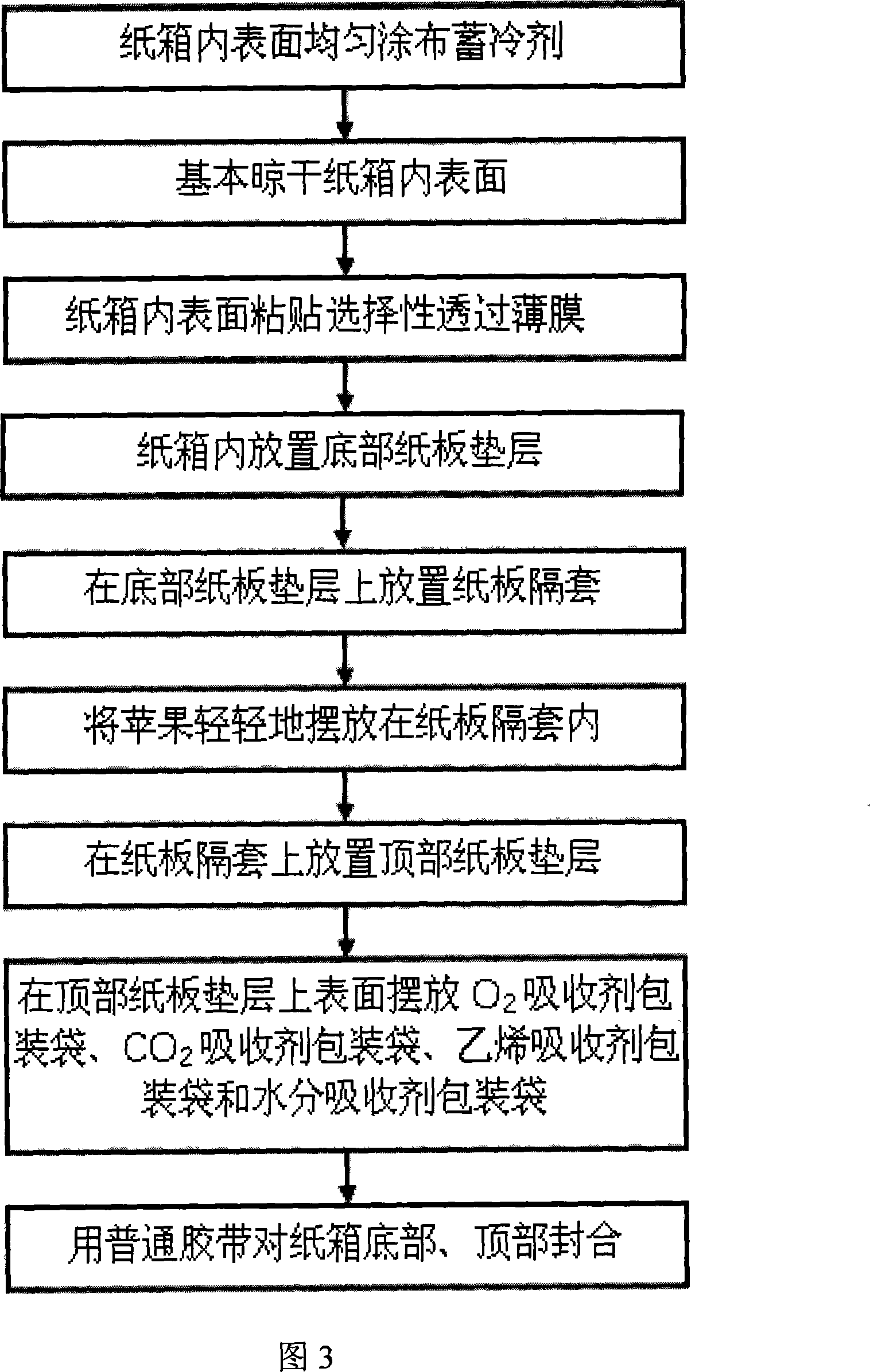

[0039] Use a carton with a length, width, and height of 380mm×240mm×180mm, with 24 apples (about 5kg) inside, and follow the steps below,

[0040] A, the inner surface of ordinary carton 1 is uniformly coated with ultra-high molecular weight sodium polyacrylate: the coating layer 2 whose proportioning ratio of water is 1: 40, and basically dries;

[0041] B, sticking polyvinylidene chloride film thickness on the inner surface of the carton of step A gained is 50 microns;

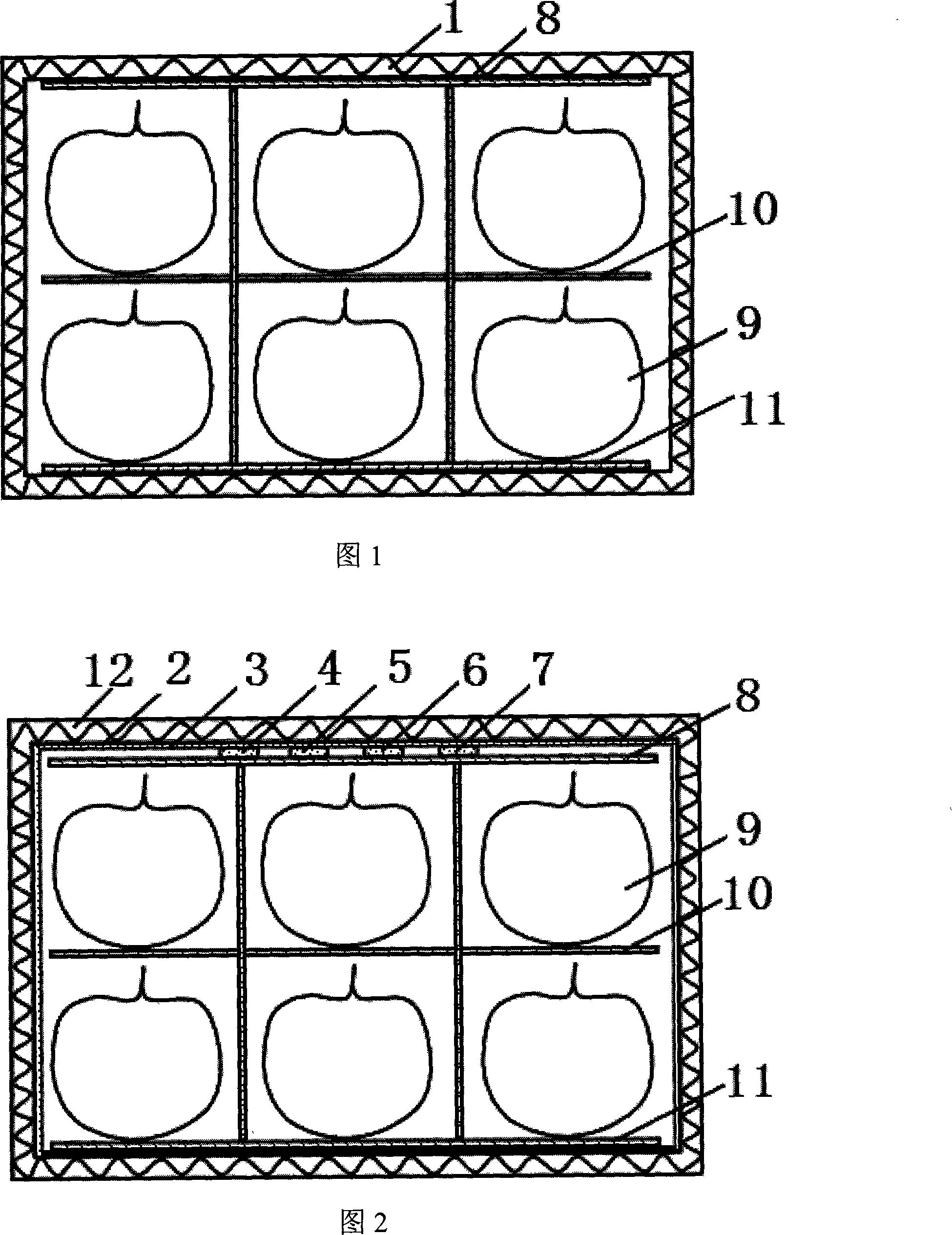

[0042] C. Place the bottom cardboard cushion 11 at the bottom of the carton obtained in step B; place the cardboard spacer 10 on the upper surface of the bottom cardboard cushion 11; gently place the apples in the cardboard spacer 10, pay attention to placing the apples Should avoid scratching the apple epidermis in the process; Place the top cardboard cushion layer 8 on the cardboard spacer 10;

[0043] D, the top cardboard cushion layer 8 upper surface of the carton gained in step C lays the oxygen absorb...

Embodiment 2

[0050] According to the step of Example 1, the amount of dry ice used is controlled to be 3.6 grams per kilogram of apples; the thickness of the polyvinylidene chloride film is 30 microns; the oxygen absorber is selected as an iron-based deoxidizer, and its consumption is 1.6 grams per kilogram of apples; The carbon dioxide absorber selects silica, and its usage rate is 4.5 grams per kilogram of apple; the ethylene absorber selects artificial zeolite fine powder, and its usage rate is 4.6 grams per kilogram of apple; the moisture absorber selects silica gel, and its usage rate is 2.5 grams per per kilogram of apples. Red Fuji apples were stored fresh for three months, and then tested for fresh storage for 1 to 3 months. The data and results are as follows:

[0051] The results of one-month fresh-keeping storage experiment were

[0052] Hardness (average): 10.35 (10 5 Pa); sugar content (average value): 12.39 (%)

[0053] The results of the 2-month fresh-keeping storage expe...

Embodiment 3

[0059] According to the step of embodiment 1, control ultrahigh molecular weight sodium polyacrylate: the ratio of water is 1: 35; The thickness of polyvinylidene chloride film is 80 microns; 2.1 grams per kilogram of apples; carbon dioxide absorber is selected from soda lime, and its dosage is 3.8 grams per kilogram of apples; ethylene absorbent can be selected from tuff fine powder, and its usage is 4.2 grams per kilogram of apples; moisture absorbent Select silica gel for use, and its consumption is 1.8 grams per kilogram of apples. Red Fuji apples were stored fresh for three months, and then tested for fresh storage for 1 to 3 months. The data and results are as follows:

[0060] The results of one-month fresh-keeping storage experiment were

[0061] Hardness (average): 10.38 (10 5 Pa); sugar content (average): 12.33 (%)

[0062] The results of the 2-month fresh-keeping storage experiment were

[0063] Hardness (average): 10.46 (10 5 Pa); sugar content (average): 14.9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com