Gel polymer electrolytes and preparation method thereof

A technology of gel polymers and electrolytes, applied in circuits, electrical components, secondary batteries, etc., can solve the problems of reduced mechanical properties, poor mechanical properties, poor interface stability, etc., and achieve improved electrical conductivity, mechanical properties and dimensional stability good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

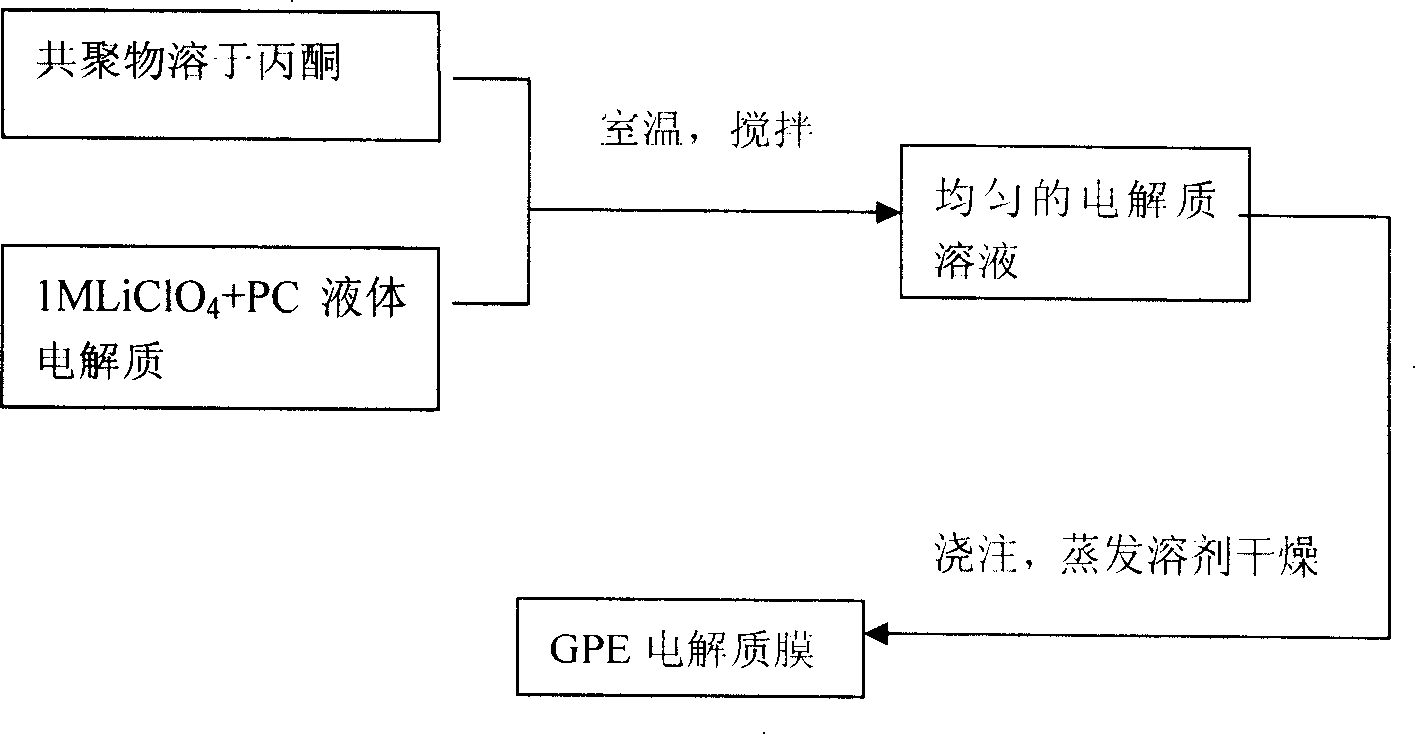

[0029] Example 1: Under stirring at room temperature, dissolve 50% copolymer in 15 mL of acetone solvent. After it is completely dissolved, add 50% liquid electrolyte solution, stir until uniform, pour it on a glass plate to form a film along the flow, Place in a desiccator. After the acetone solvent was completely volatilized, a GPE-50 film was obtained.

Embodiment 2

[0030] Example 2: Under stirring at room temperature, dissolve 55% copolymer in 15 mL of acetone solvent. After completely dissolving, add 45% liquid electrolyte solution, stir until uniform, and pour it onto a glass plate to form a film along the flow. Place in a desiccator. After the acetone solvent was completely volatilized, a GPE-55 film was obtained.

Embodiment 3

[0031] Example 3: Under stirring at room temperature, dissolve 60% copolymer in 15mL of acetone solvent. After completely dissolving, add 40% liquid electrolyte solution, stir until uniform, pour it on a glass plate to form a film along the flow, Place in a desiccator. After the acetone solvent was completely volatilized, a GPE-60 film was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com