Nylon66/phyllosilicate nano composite material and preparation method thereof

A nano-composite material, layered silicate technology, applied in the field of materials, can solve the problems of increased layer spacing of layered brick silicate, poor product performance, influence, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

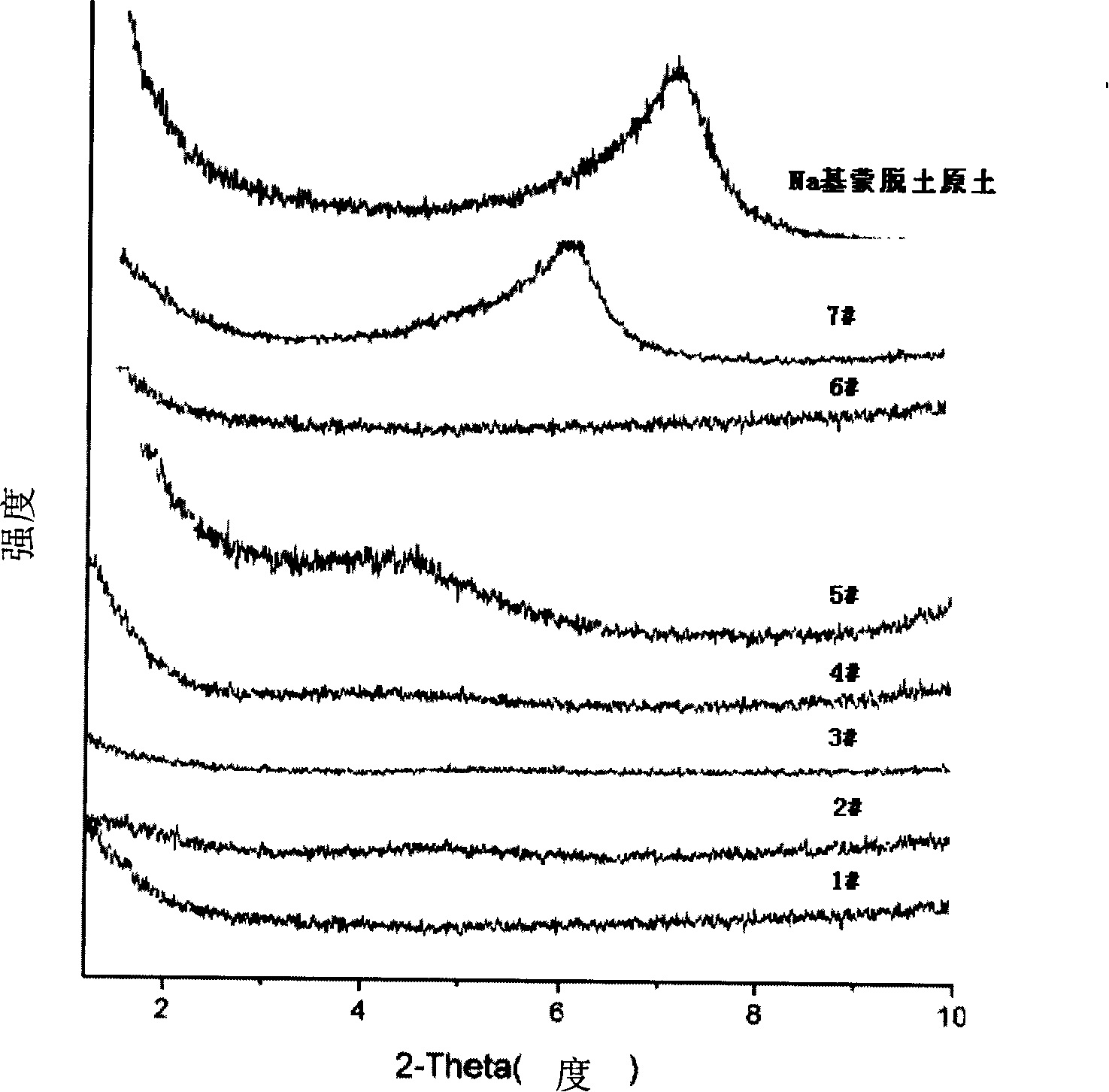

Image

Examples

preparation example Construction

[0057] The preparation method of the present invention is described as follows:

[0058] Preparation

[0059] The preparation method of the present invention comprises the following steps:

[0060] (a) providing an aqueous dispersion of layered silicate raw soil, wherein the weight ratio of layered silicate raw soil to water is 2 to 200;

[0061] (b) providing a mixture of the aqueous dispersion (containing 0.1 to 10 parts by weight of layered silicate raw soil) and 99.9 to 90 parts by weight of nylon 66 salt in step (a), the mixture undergoes polycondensation reaction to obtain the nano composite material.

[0062] In a preferred embodiment of the present invention, the object of the present invention can be achieved through the following technical solutions:

[0063] Dispersion of phyllosilicate: First, disperse a certain amount of phyllosilicate in 2-200 times the aqueous solution, stir in a water bath at 80°C for 2 hours, add a certain amount of nylon 66 salt to dispers...

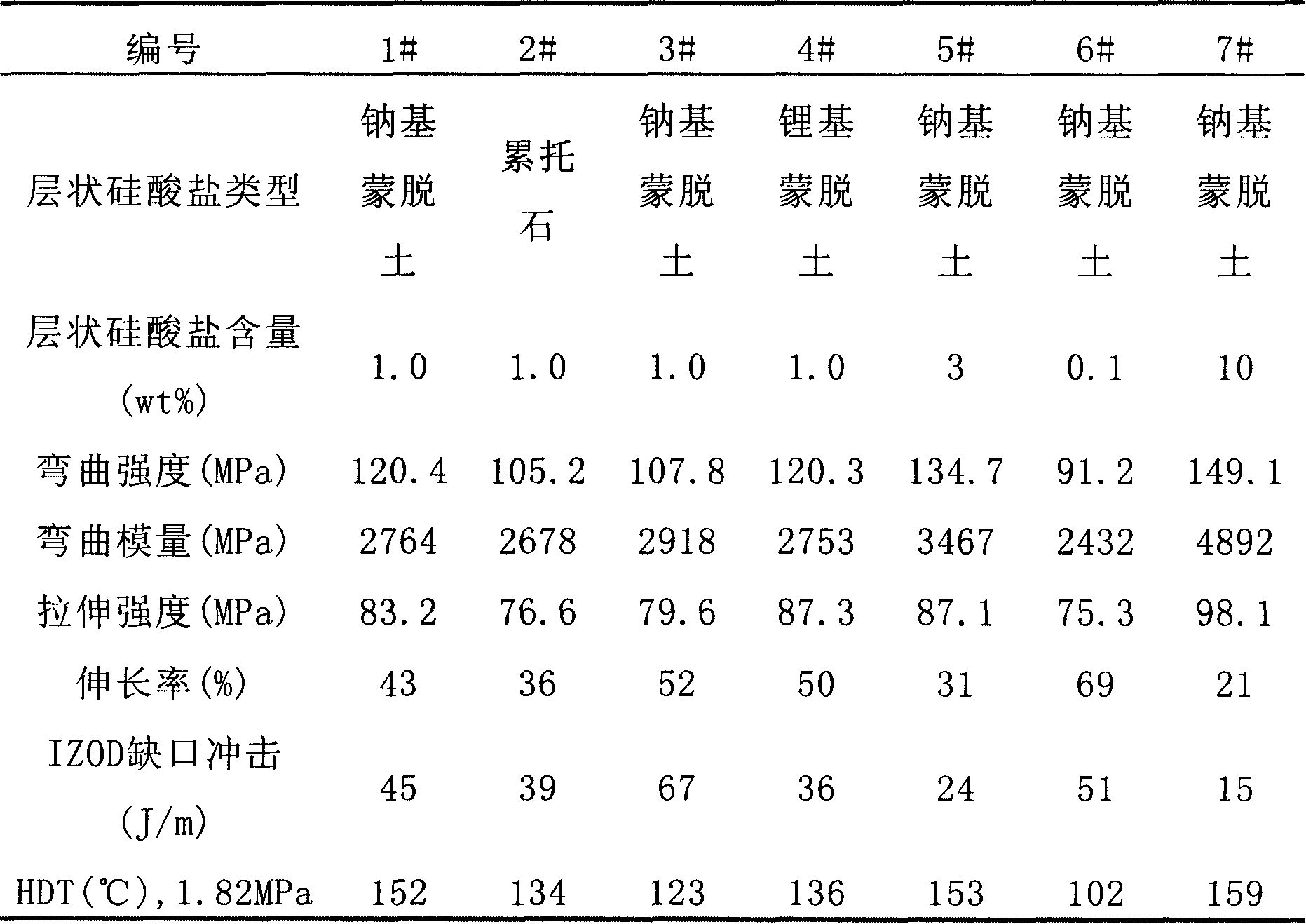

Embodiment 1

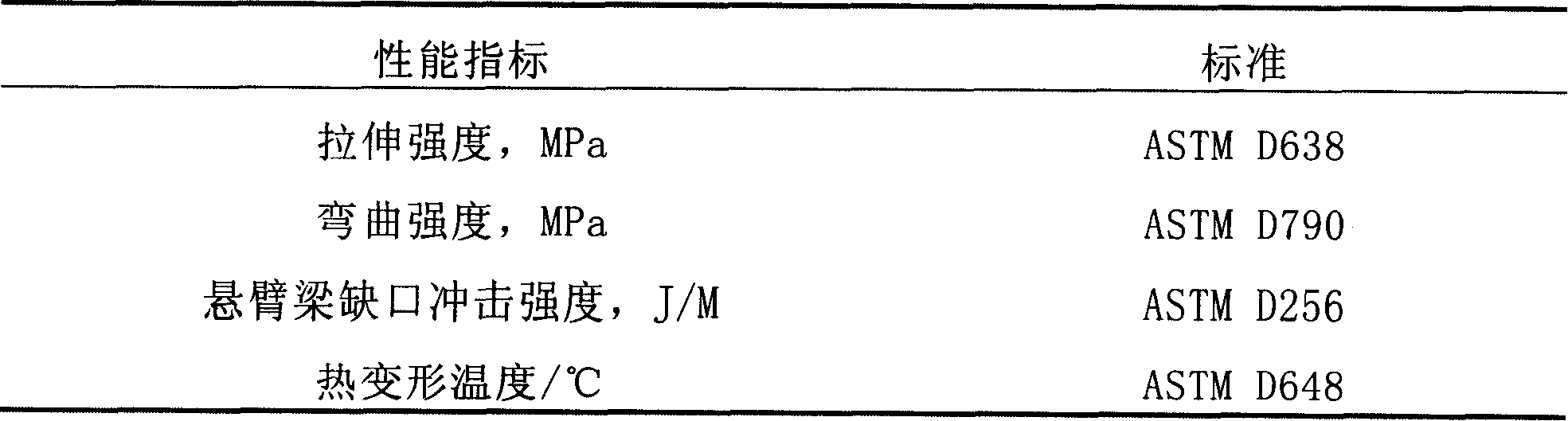

[0087] Put 10 g of nano-based montmorillonite in 1000 g of distilled water, stir in a water bath at 80° C. for 2 hours, and let stand for 10 minutes to remove impurities precipitated at the bottom. Then add 1000 g of hexamethylenediamine adipate to dissolve in it, disperse evenly, and then ultrasonically disperse for 2 hours. Part of the water is removed in a rotary evaporator so that the water content is 20-40% of the total weight of the mixture; the temperature of the water bath is controlled below 90°C. Put it into the reaction kettle and raise the temperature to 270-280°C, keep the pressure at 0.8MPa, and react for 3 hours. React under normal pressure for 1 hour, and finally keep the vacuum for 1 hour, and discharge. The properties of the prepared montmorillonite / nylon 66 nanocomposite material 1# are shown in attached table 2.

Embodiment 2

[0089] Same as in Example 1, except that the nano-based montmorillonite is changed to rectorite, and the properties of the prepared rectorite / nylon 66 nanocomposite material 2# are shown in attached table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com