Method for purifying cultivation sewage by 'marine sponge-microalgae' integration system

An integrated system and aquaculture wastewater technology, applied in the field of bioremediation, can solve problems such as polluting the environment and wasting resources, and achieve the effects of good effect, increased biomass and simple procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

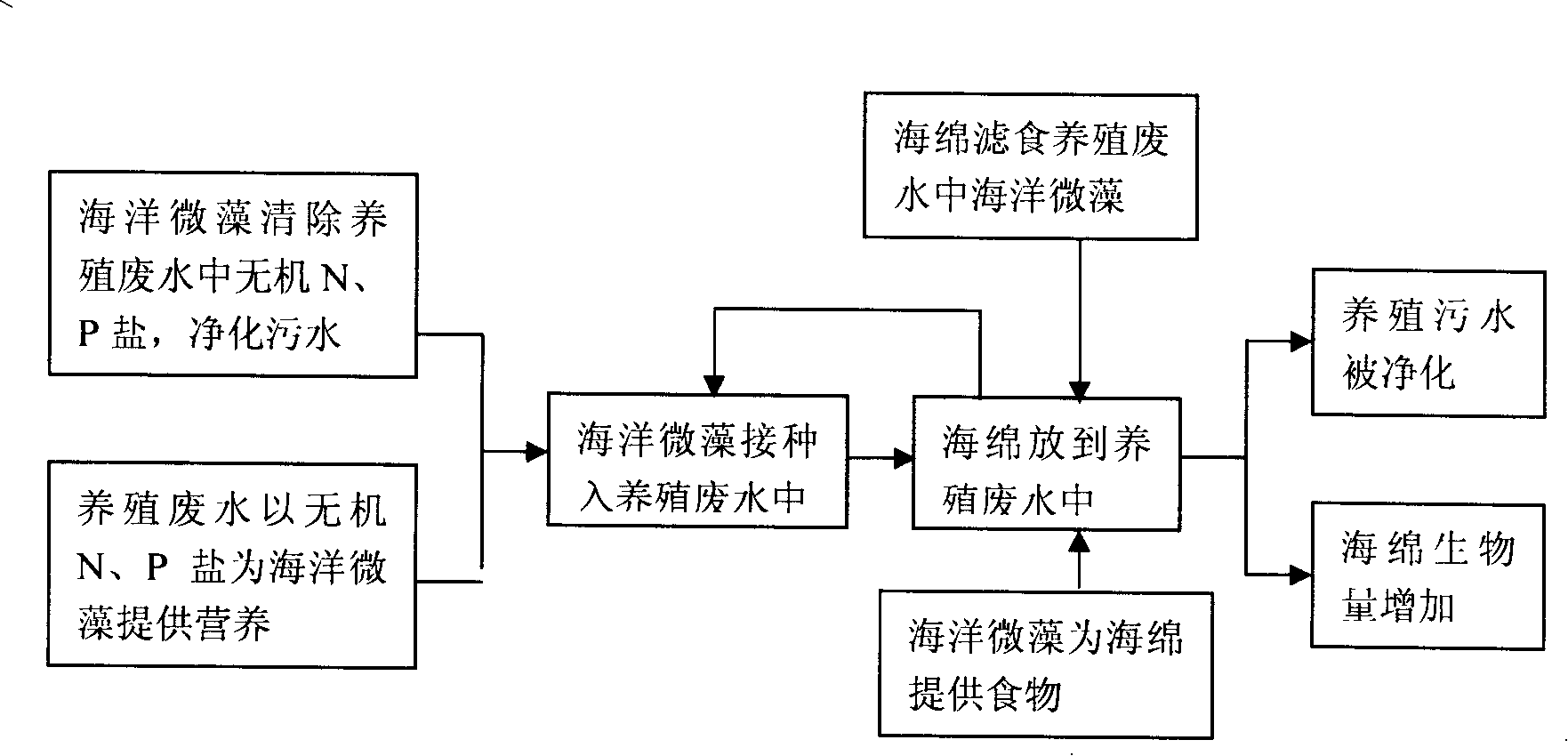

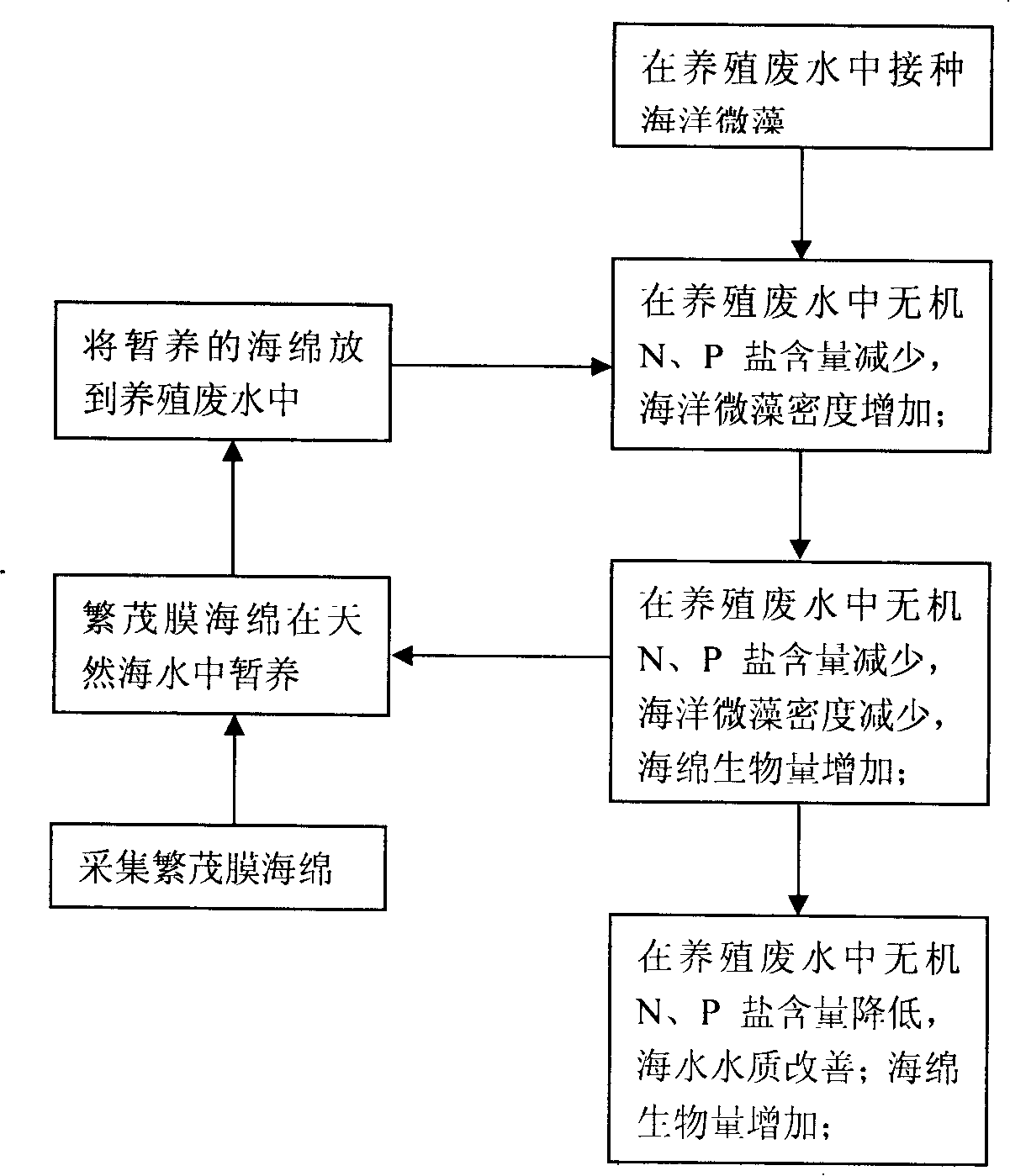

[0024] The following is attached figure 1 with 2 The implementation process of the technology of the present invention is described in detail.

[0025] 1. Collect sponges in the intertidal sea area, wash them with natural sea water, put them in an incubator with refrigeration facilities, and quickly transport them to the temporary breeding place.

[0026] 2. In the temporary breeding place, rinse the sponge with sand filter seawater three times, put the sponge block into a 200L aquarium filled with flowing natural seawater and inflate it, and raise it temporarily at 10-23°C for 2-3 days. Temporary breeding density is not more than 0.5-3‰ (sponge biomass-g / seawater volume-L), daily water change: 1-4 times the volume of the temporary cultivation pool.

[0027] 3. Marine bait microalgae (such as Nitzschia crescentus) are cultivated at high density in algae pools (add Conway nutrient salts, 3000lx light intensity, light-to-dark ratio of 14:10 per day, and a culture temperature o...

Embodiment 2

[0040] The role of inorganic N and P salts in the "sponge-microalgae" integrated system for sterilization of aquaculture wastewater:

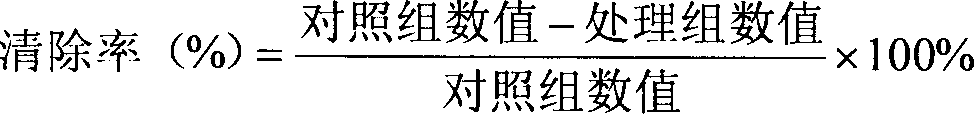

[0041] In order to explore the feasibility of the "microalgae-sponge" integrated system to remove inorganic N and P salts in seawater, about 70×10 4 Cells / mL marine microalgae (Nitzeria lunata) were used for experiments, and the temperature was controlled at 10-23°C. In the experiment, 10L of sand-filtered seawater was added to four 14L aquariums, which were boiled and sterilized, and allowed to cool to room temperature. Add a certain density of marine microalgae (Nitzeria crescentus) respectively in 3 aquariums, wherein 2 aquariums put into sponge as treatment group 1 and 2 (T-1 and T-2), 1 aquarium does not A sponge was put in as control 2 (C-2). The fourth aquarium was kept without algae or sponge as control 1 (C-1). When the algae growth just reached the exponential growth phase, nutrient salts (the nutrient salts of simulated aquacultur...

Embodiment 3

[0046] The role of the "sponge-microalgae" integrated system in removing inorganic N and P salts in actual aquaculture wastewater:

[0047] The experimental conditions for the "microalgae-sponge" integrated system to remove inorganic N and P salts in sea cucumber aquaculture wastewater are the same as those in "Example 1", except for the following points: (1) replace "Example 1" with actual sea cucumber aquaculture wastewater 1” Sterilized sand-filtered seawater boiled and cooled to room temperature in the experiment; (2) Marine microalgae (Nitztophthora lunata) with an initial inoculation density of about 50×104cells / mL were used. The removal rate results of the "sponge-microalgae" integrated system for removing inorganic N and P salts in actual aquaculture wastewater are shown in Table 2.

[0048] Table 2: The removal rate of inorganic N and P salts in actual aquaculture wastewater by the "sponge-microalgae" integrated system

[0049]

[0050]

[0051] In the experime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com