Advanced treatment recycling technique of urban sewage

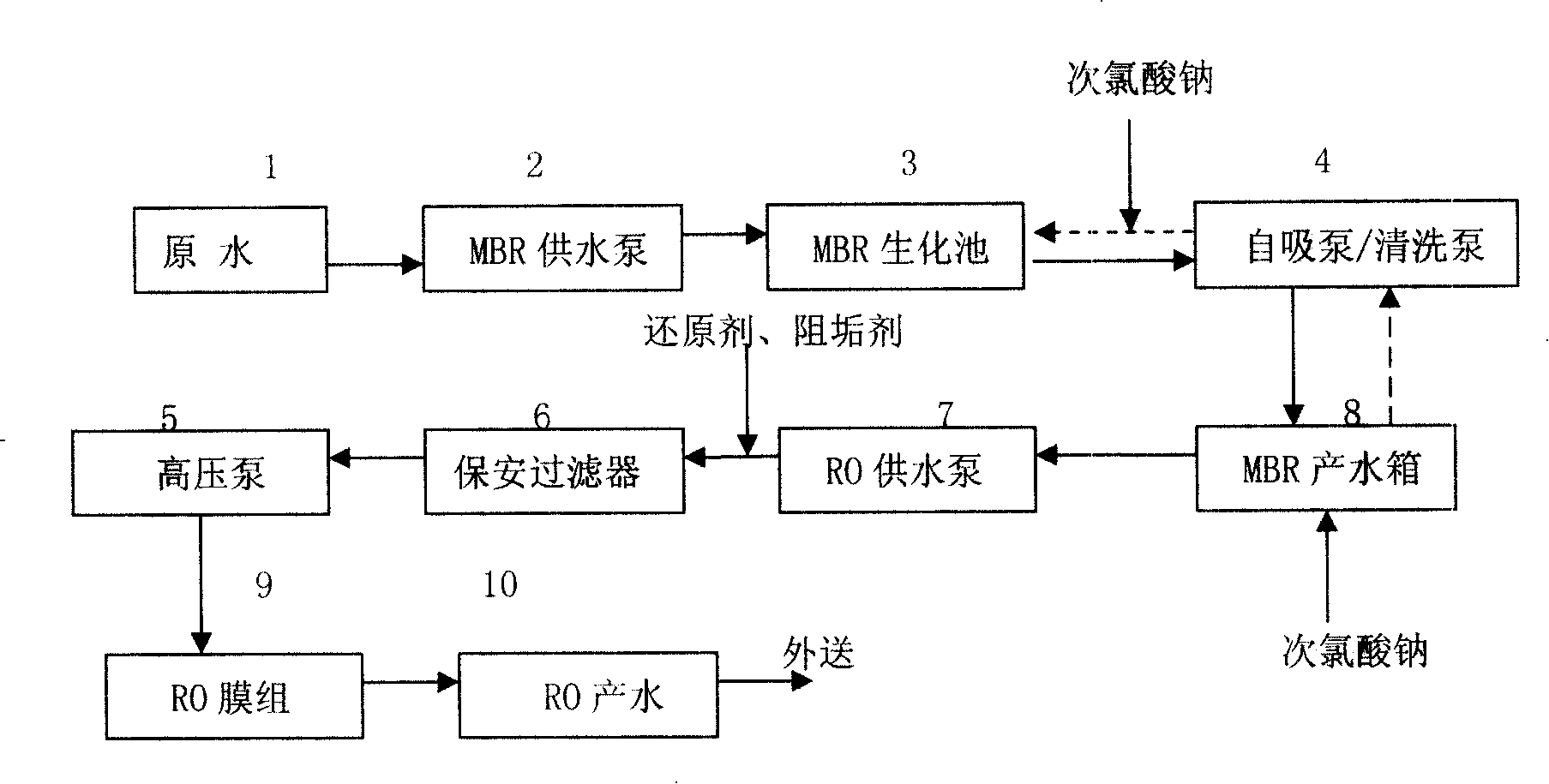

A technology for advanced treatment of urban sewage, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, osmosis/dialysis water/sewage treatment, etc. It can solve the problem of high salt concentration in effluent and insufficient water reuse Requirements and other issues to achieve the effect of reducing environmental pollution, reducing emissions, and solving water problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

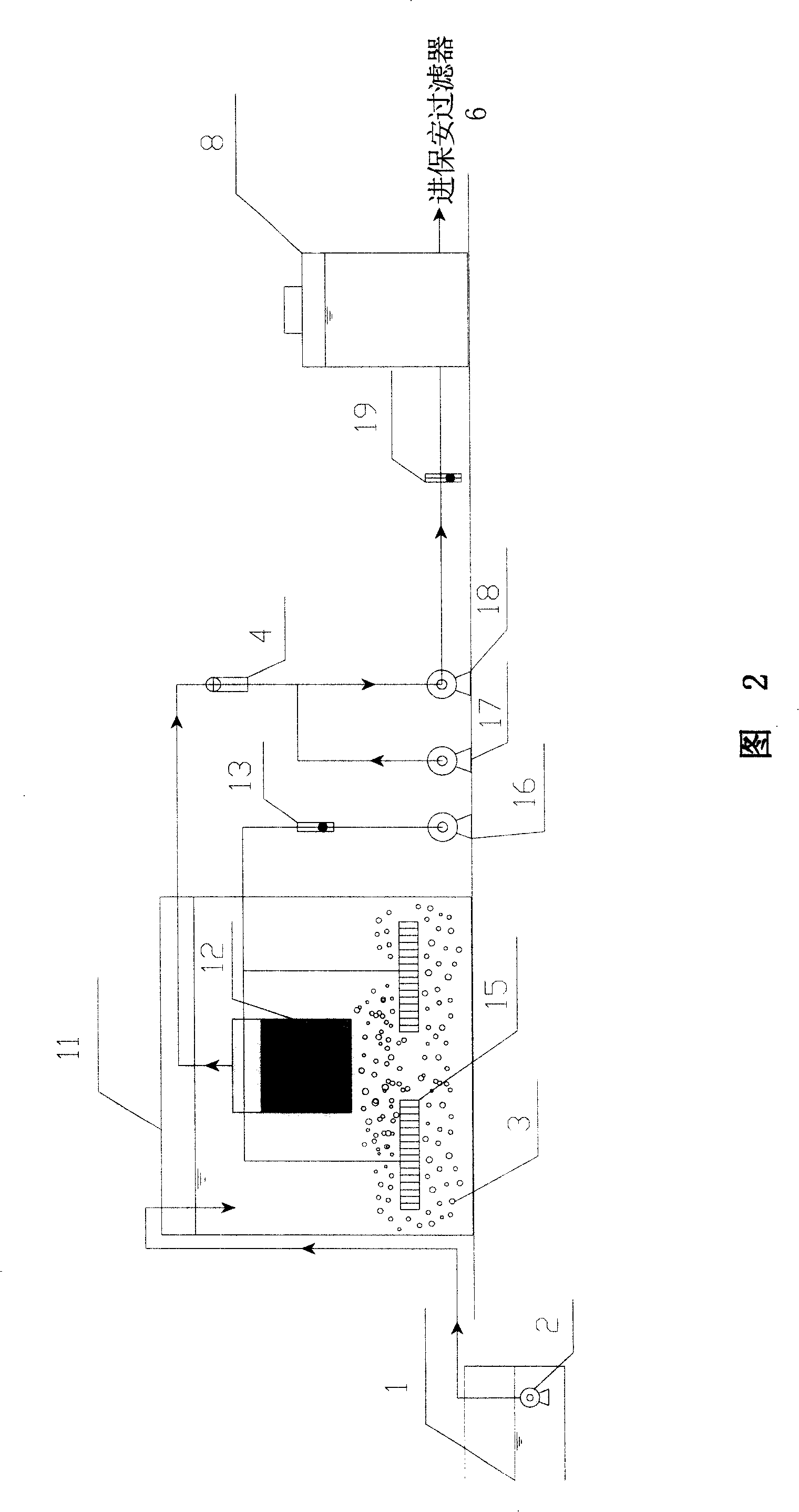

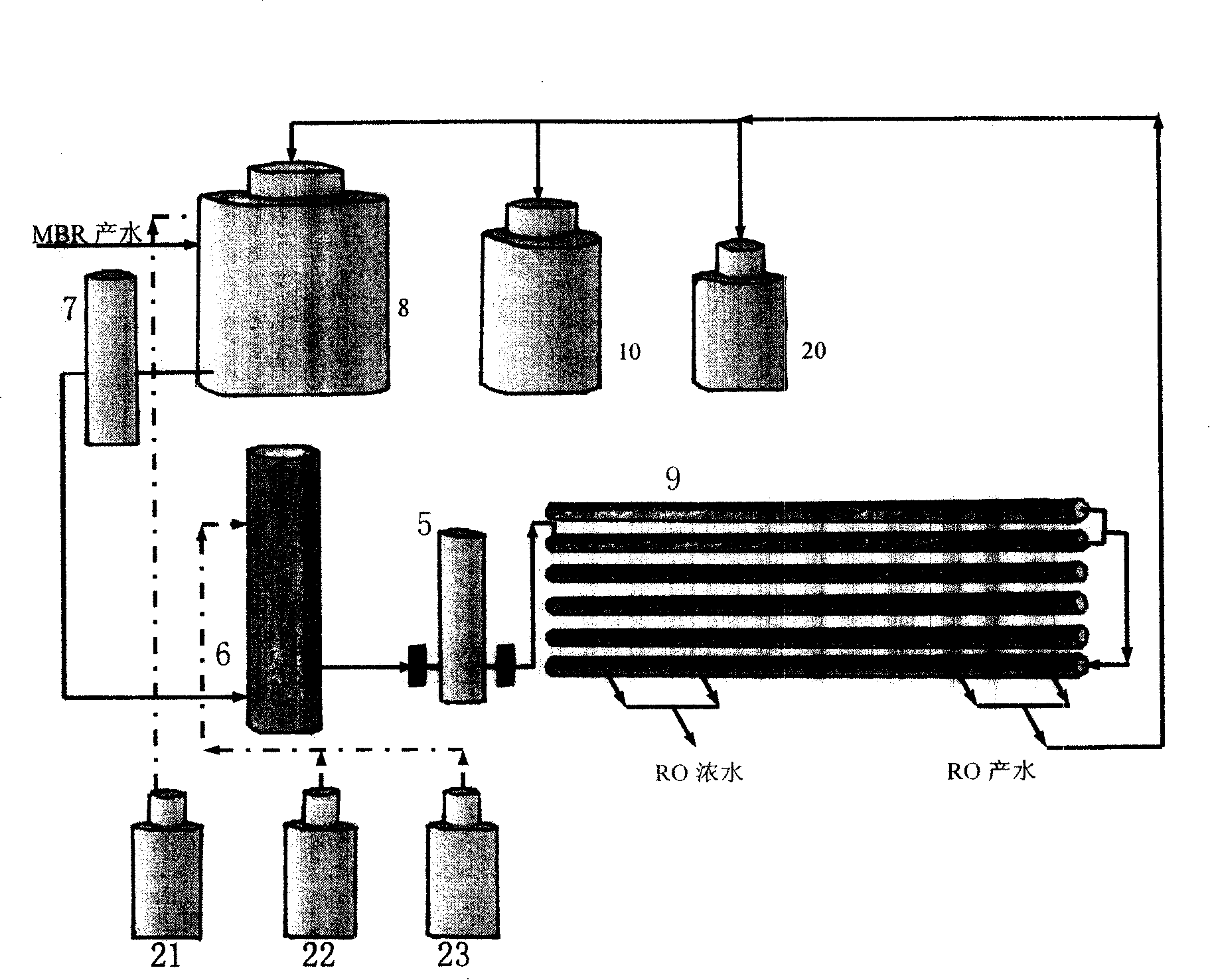

[0056] The cooling water reuse process of a cold rolling steel plant adopts the above-mentioned MBR+RO system of the present invention to treat the urban secondary discharge water, and the water after RO treatment is blended to reuse cooling water for cold rolling steel. The pretreatment water volume of this project is 10000m 3 / D, where (MBR) water production is 450m 3 / h, reverse osmosis water production 300m 3 / h.

[0057] Process parameters:

[0058] MBR membrane module: Mitsubishi Rayon: SUR-334

[0059] Effective membrane area: 3m 2 × 40 pieces = 120m 2

[0060] Component specifications: 663.5mm×1538mm×1441.5mm

[0061] Design flux: flux 15LMH=8.8GFD;

[0062] Single membrane water production: 1.8m 3 / h;

[0063] MBR system running time: 23 hours, stop aeration for 1 hour;

[0064] Design scale per unit time of MBR system: 626m 3 / h

[0065] MBR system membrane module quantity: 350 groups

[0066] MBR membrane area: 43000m 2

[0067] Reverse osmosis (RO) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com