Coagulation decolourant for printing and dyeing waste water

A technology for printing and dyeing wastewater and decolorizing agent, which is applied in the textile industry wastewater treatment, flocculation/sedimentation water/sewage treatment and other directions, can solve the problems of increasing free nitrogen content, high price of dicyandiamide, difficulty in promotion and use, etc. The effect of prolonging the reaction time and good decolorization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

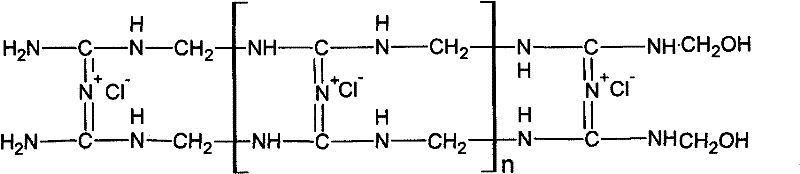

[0045] Synthesis of A polymer:

[0046] Add 1 mol of dicyandiamide, 1.15 mol of ammonium chloride, 0.01 mol of catalyst urea, and 0.95 mol of formaldehyde into a three-necked round-bottomed flask equipped with a reflux condenser, slowly raise the temperature to 45°C, and slowly add another 0.95 mol of formaldehyde, and the addition is complete. Raise the temperature to 92°C, react for 6 hours, and adjust the pH to about 4.0 with sodium hydroxide. The obtained colorless viscous liquid is dicyandiamide-formaldehyde polymer, and its solid content is 58.2%.

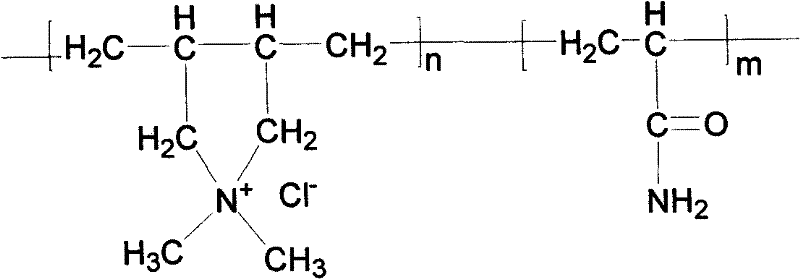

[0047] Synthesis of B polymer:

[0048] Dissolve 4 mol of DADMAC monomer in 500 ml of water, control the temperature at 20° C., fill with nitrogen to obtain oxygen for 30 minutes, and use 15 g of ammonium persulfate as an initiator. Add 1molAM under nitrogen protection. After that, add 0.2molAM every 10 minutes until the addition is finished. A total of 2 mol AM was added. React at 70°C for 4 hours to obtain an aqueous so...

Embodiment 2

[0052] Synthesis of A polymer:

[0053] Add 1 mol of dicyandiamide, 1.175 mol of ammonium chloride, 0.01 mol of catalyst urea, and 1.019 mol of formaldehyde in a three-neck round bottom flask equipped with a reflux condenser, slowly raise the temperature to 45°C, slowly add another 1.0 mol of formaldehyde, and heat up after adding to 92°C, react for 7.5 hours, adjust the pH to about 4.0 with sodium hydroxide, and obtain a colorless viscous liquid dicyandiamide-formaldehyde polymer with a solid content of 58.8%;

[0054] Synthesis of B polymer:

[0055] Dissolve 2 mol of DADMAC monomer in 500 ml of water, control the temperature at 20°C, fill with nitrogen and oxygen for 30 minutes, and use 15 g of ammonium persulfate as an initiator. Add 1molAM under nitrogen protection. After that, add 0.1molAM every 10 minutes until the addition is finished. A total of 2 mol AM was added. React at 65°C for 4 hours to obtain an aqueous solution with a solid content of 20%, and add water t...

Embodiment 3

[0059] Synthesis of A polymer:

[0060] Add 1 mol of dicyandiamide, 1.60 mol of ammonium chloride, 0.01 mol of catalyst urea, and 0.7 mol of formaldehyde into a three-necked round-bottomed flask equipped with a reflux condenser, slowly raise the temperature to 45°C, and slowly add another 0.75 mol of ammonium chloride and another 0.5 mol formaldehyde, after adding, heat up to 90°C, react for 8 hours, adjust the pH to about 4.0 with sodium hydroxide, and the obtained product A polymer is a colorless viscous liquid with a solid content of 58.45%;

[0061] Synthesis of B polymer:

[0062]Dissolve 2.5 mol of DADMAC monomer in 300 ml of water, control the temperature at 25°C, fill with nitrogen and oxygen for 30 minutes, and use 15 g of ammonium persulfate as an initiator. Add 1molAM under nitrogen protection. After that, add 0.1molAM every 150 minutes until the addition is finished. A total of 2 mol AM was added. React at 65°C for 5 hours to obtain an aqueous solution with a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com