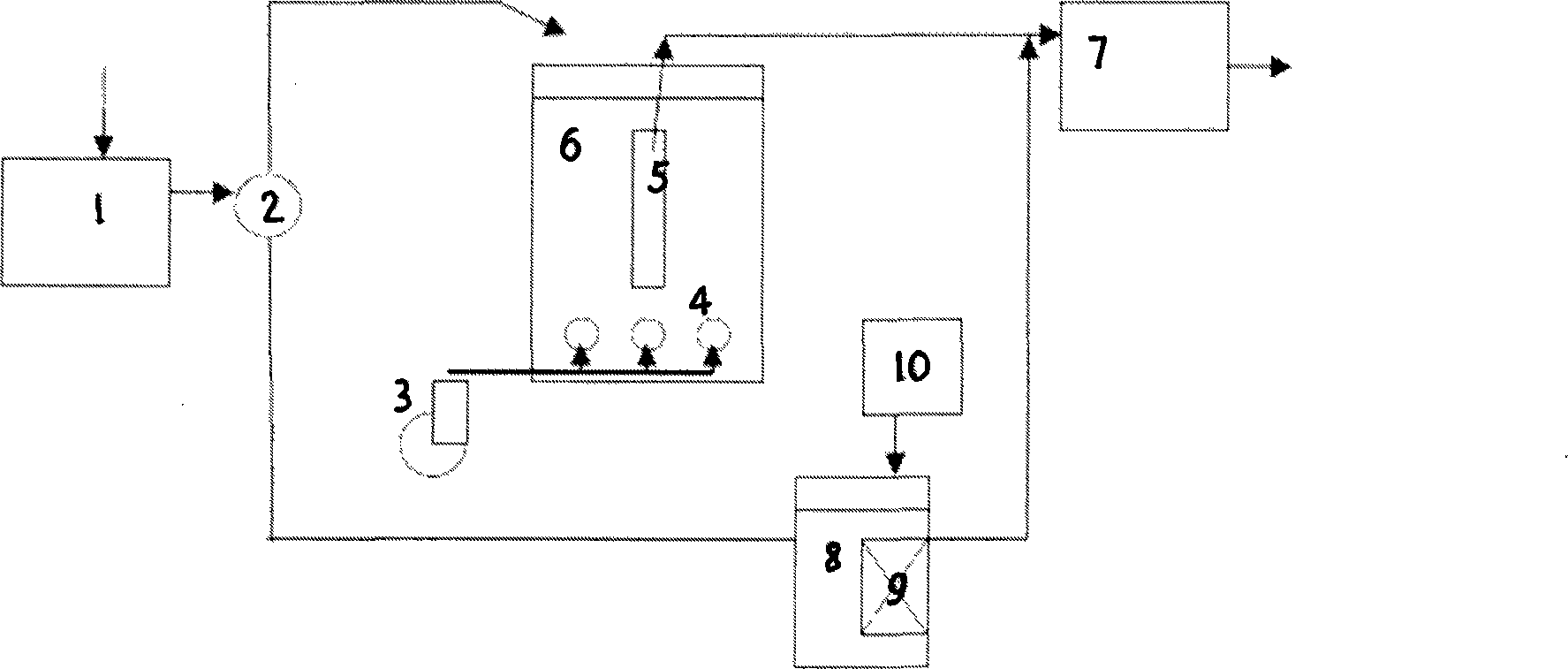

A/O/A embranchment direct current biological denitrogenation method for treating coking waste water

A coking wastewater and biological denitrification technology, applied in the field of environmental engineering, can solve the problems of scale-up, heavy burden on the aerobic section, high energy consumption, etc., and achieve the effects of reducing costs, improving biochemical performance, and simplifying operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] After coking wastewater was pretreated by air flotation, COD cr 2750mg / L, NH 4 + -N94mg / L, water volume 2m 3 / h, as the influent of anaerobic filter 1. The size of the anaerobic filter is 3 × 5 × 4m, and the super height is 0.5m; the honeycomb cell wall fiber filter material is installed from 0.3m below the water surface. The bottom is blown with oxygen-free gas to form an air-lift cycle to obtain an efficient mixing reaction rate. The size of the MBR aeration tank 6 is 3×11×4m, and a partition wall is set every 2m in the middle to form a diversion corridor. The last corridor is 3m wide, with vertical deflectors, forming a membrane bioreactor with airlift circulation. The outer dimensions of the filter membrane module 5 are 2×1.8×2.4m, and the membrane area is 150m 2 , sludge concentration 11.2g / L. The water volume distributor 2 distributes according to the ratio of 1:9, and the ratio of entering the aerobic treatment branch is 90%. The size of the carbon source ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com