Method for producing butadiene rubber bromide

A technology of brominated butyl rubber and a production method, which is applied in the production field of brominated butyl rubber, can solve the problems that the technical parameters of the preparation method are not specifically involved, the product quality is unstable, and the reaction process is not easy to control, etc., and the reaction process is easy , The effect of stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

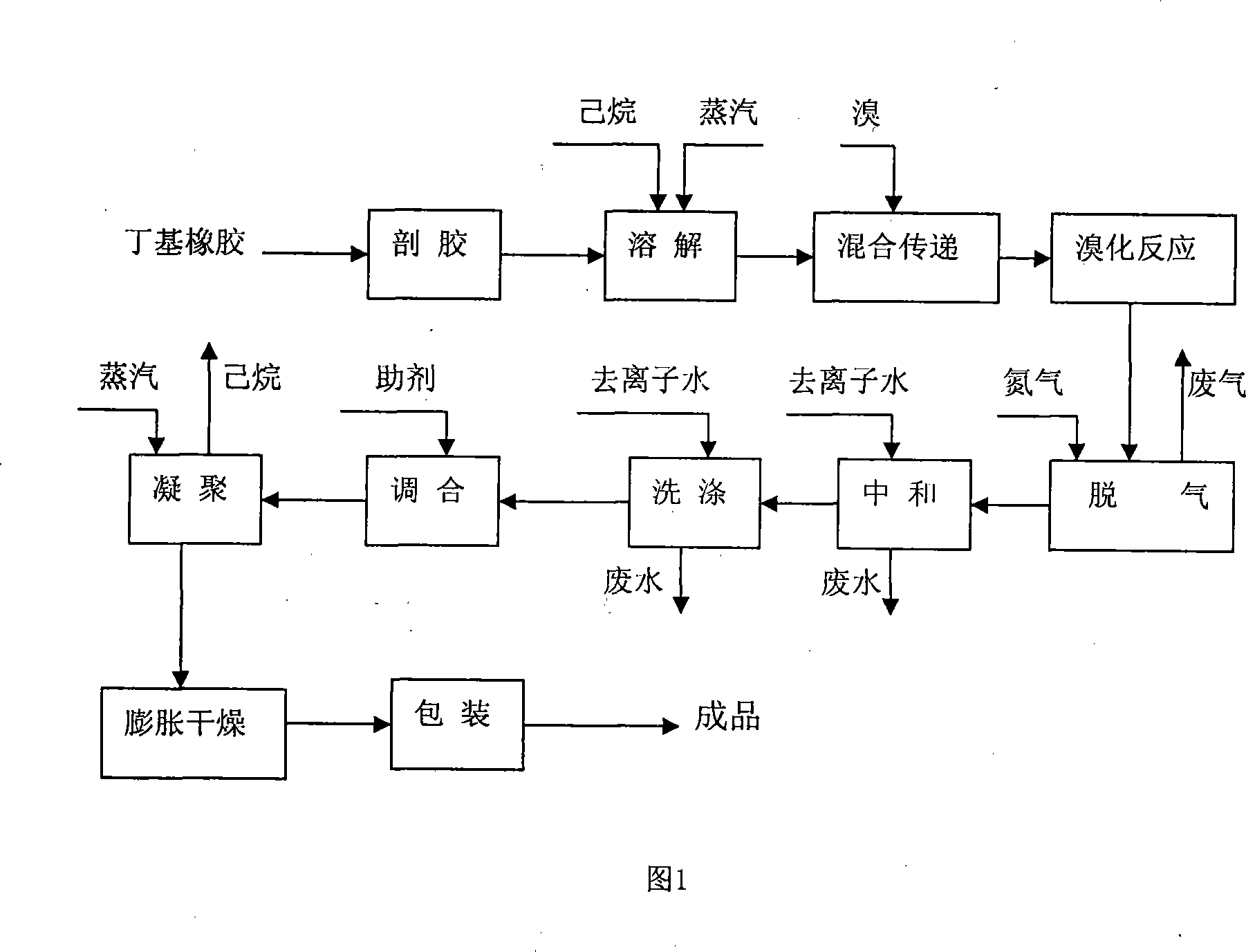

[0016] Referring to Figure 1, first cut butyl rubber into small pieces of about 1 to 2 cm with a special glue cutter to facilitate the dissolution of butyl rubber, then add hexane solution into the reaction kettle, and put small pieces of Butyl rubber is dissolved. In order to ensure the smooth bromination of the glue, and considering the energy loss of post-processing, the concentration of butyl rubber in the hexane solution is controlled between 8% and 20%, and the temperature in the reactor is kept at 45°C to 65°C. between ℃.

[0017] Bromination reaction is the key technology of this process. Brominated butyl rubber (BIIR) is a product obtained after bromination of butyl rubber (IIR). Although the reaction is a free radical reaction, the reaction speed is still quite fast, and During the reaction process, bromine (Br) reacts with unsaturated isoprene to form the structure of bromobutyl rubber, which has a very important influence on the quality of rubber. This reaction r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com