Light degradation antibiotic polylactic acid material and preparation method thereof

A polylactic acid and photodegradation technology, which is applied in the field of composite materials to achieve the effects of enhancing interaction, achieving uniform and stable dispersion, and improving glass transition temperature and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

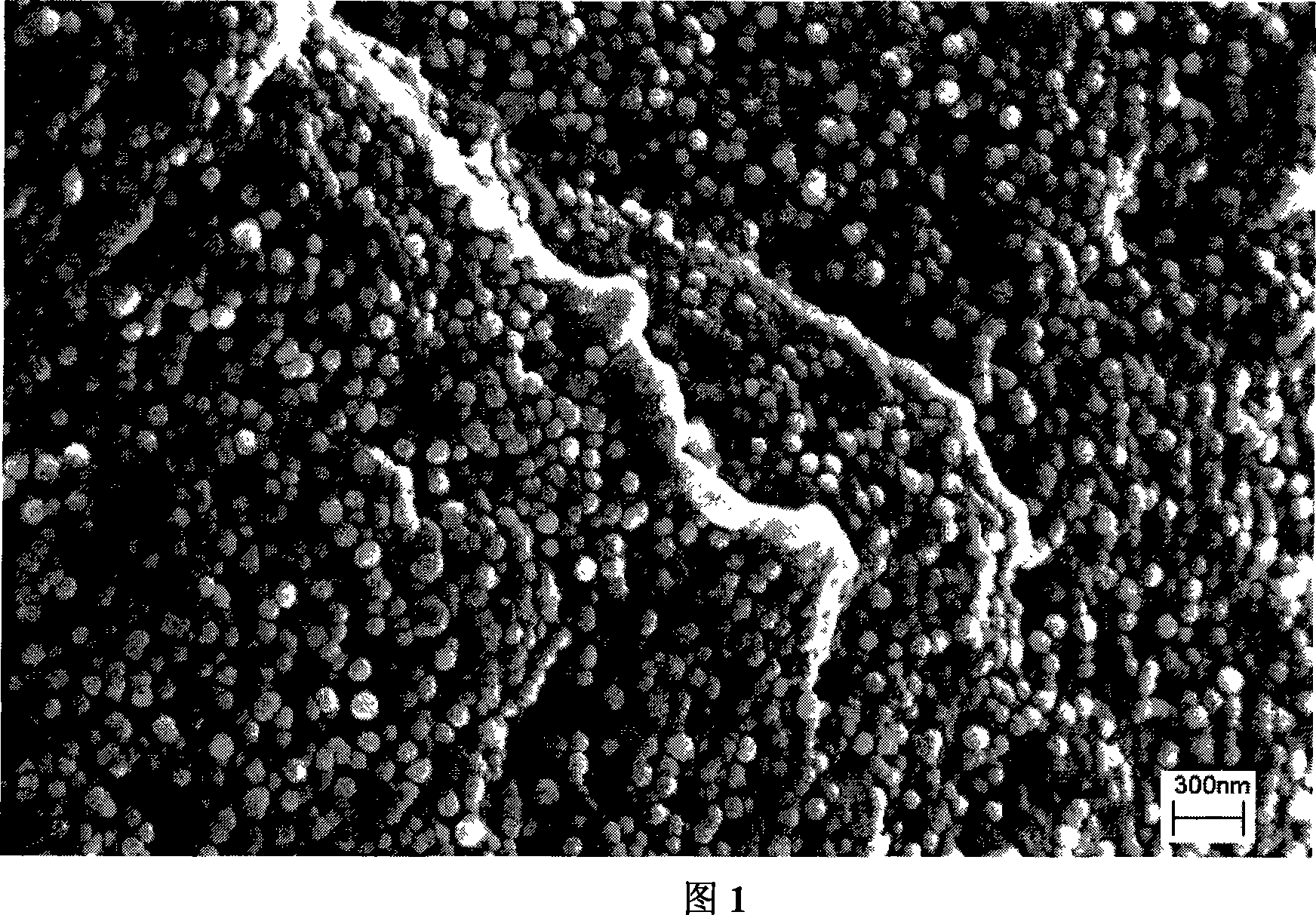

[0031] 2. Preparation of photodegradable antibacterial polylactic acid composites

[0032] TiO with lactide and different contents organically treated 2 (organized TiO 2 The mass fraction is 1.0wt%, 3.0wt%, 5.0wt%, 10wt%) respectively into 5 straight sealed tubes, add the tetrahydrofuran solution of stannous octoate and magneton stirring, vacuumize under the protection of nitrogen atmosphere Seal the tube, place the sealed tube in an oil bath at 150°C for 2 hours, and then polymerize at 150°C for 24 hours to prepare PLA substrate and nano-TiO 2 / PLA composite material, marked as TiO 2 -x / PLA (x is TiO 2 quality score). The prepared samples are stored in a desiccator for later use after being hot-pressed to form a film or a solution to form a film.

Embodiment 1

[0034] 1. TiO 2 organic treatment

[0035] 6g anatase nano-TiO 2 Mix with 300mL butanone, ultrasonically disperse for 10min, mix with 300mL butanone solution containing 2.4g KH570 silane coupling agent (γ-methylacetoxypropyltrimethoxysilane), and reflux at 80°C for 3h. Cool to room temperature, centrifuge and dry at 100°C to obtain organically treated TiO 2, stored in a desiccator for later use. The properties of the material treated with acetone are similar to those obtained by the butanone treatment.

[0036] 2. Preparation of photodegradable antibacterial polylactic acid composites

[0037] The purified lactide and the organically treated TiO with a mass fraction of 1.0wt% 2 Put it into a straight sealed tube, add the tetrahydrofuran solution of stannous octoate and stir with a magnet, evacuate and seal the tube under the protection of a nitrogen atmosphere, put the sealed sealed tube in an oil bath at 150°C for 2 hours, and then Polymerize at 150°C for 24h to prepare...

Embodiment 2

[0038] Embodiment 2: carry out nano-TiO according to the method described in embodiment 1 2 The difference is that the dispersant is triethylamine, the reagent used for organic modification is titanate coupling agent (NDZ105, isopropyl trioleic acid acyloxy titanate), other treatment methods and reaction conditions are the same.

[0039] According to the method described in Example 1, the purification of lactide and the preparation of photodegradable antibacterial polylactic acid composite materials are carried out, the difference is that the catalyst is stannous chloride, and the used nanometer TiO 2 The mass fraction of lactide is 3.0wt% of lactide, other treatment methods and reaction conditions are all the same, and the obtained composite material is marked as TiO 2 -3 / PLA.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com