Colloidal sols gelatin synthesizing method for leadless piezoelectric ceramic lithium sodium kalium niobate nano-powder

A nano-powder, lead-free piezoelectric technology, applied in the field of piezoelectric ceramic material preparation, can solve the problems of restricting the industrialization of niobate powder, high price of niobium ethanol, cumbersome use and operation, etc., and achieve a narrow range of size distribution , high sintering activity, and the effect of lowering the synthesis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) The product obtained by mixing niobium pentoxide and potassium pyrosulfate in a molar ratio of 1:8 and calcining at 300°C for 2 hours was dissolved in deionized water; then the pH value was titrated to 2 with nitric acid to obtain a white precipitate; the obtained product was centrifuged The white precipitate is dissolved in oxalic acid solution, and after stirring, a clear and transparent niobium-containing oxalic acid solution A is obtained;

[0019] (2) Titrate the niobium-containing oxalic acid solution A obtained in step 1 with ammonia water to a pH value of 10, and obtain a white precipitate B through centrifugation and deionized water washing;

[0020] (3) press piezoelectric ceramic lithium sodium potassium niobate (Li0.06Na0.47K0.47) NbO Composition ratio, lithium carbonate, sodium carbonate and salt of wormwood are dissolved in acetic acid and make solution, this solution and step 2 obtain The white precipitate B was added to the citric acid aqueous soluti...

Embodiment 2

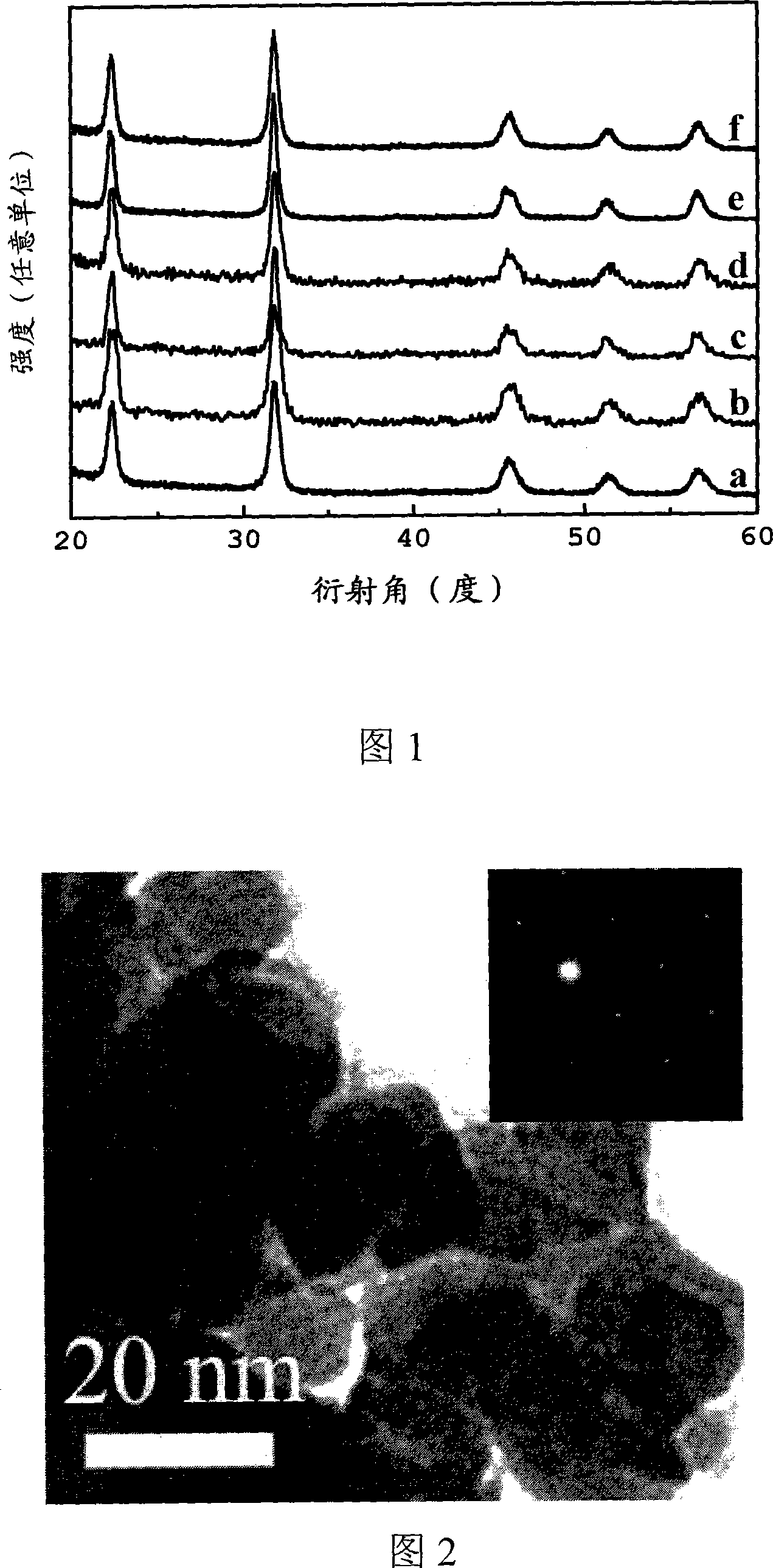

[0026] Mix niobium pentoxide and potassium pyrosulfate at a molar ratio of 1:8 and calcinate at 280°C for 1 hour to dissolve in deionized water; then titrate the pH value to 3 with nitric acid; Calcination 2h, all the other conditions are the same as in Example 1. Prepare ceramic powder b. The powder X-ray diffraction pattern of product b is shown in Figure 1.

Embodiment 3

[0028] The product obtained by mixing niobium pentoxide and potassium pyrosulfate at a molar ratio of 1:8 and calcining at 320°C for 2 h was dissolved in deionized water; the niobium-containing oxalic acid solution A was titrated with ammonia water to a pH value of 11; the transparent sol C was Dry at 120°C for 48 hours to obtain a transparent xerogel D; the intermediate product E obtained above was calcined at 600°C for 5 hours, and the rest of the conditions were the same as in Example 1. Prepare ceramic powder c. The powder X-ray diffraction pattern of product c is shown in Figure 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com