Integrated opto-electronic device for generating high-frequency microwave by SOA four-wave mixing effect

An optoelectronic device, four-wave mixing technology, applied in the direction of electro-solid devices, laser parts, lasers, etc., can solve the problems of large and complex systems, poor stability, high cost, high integration, low cost and high yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

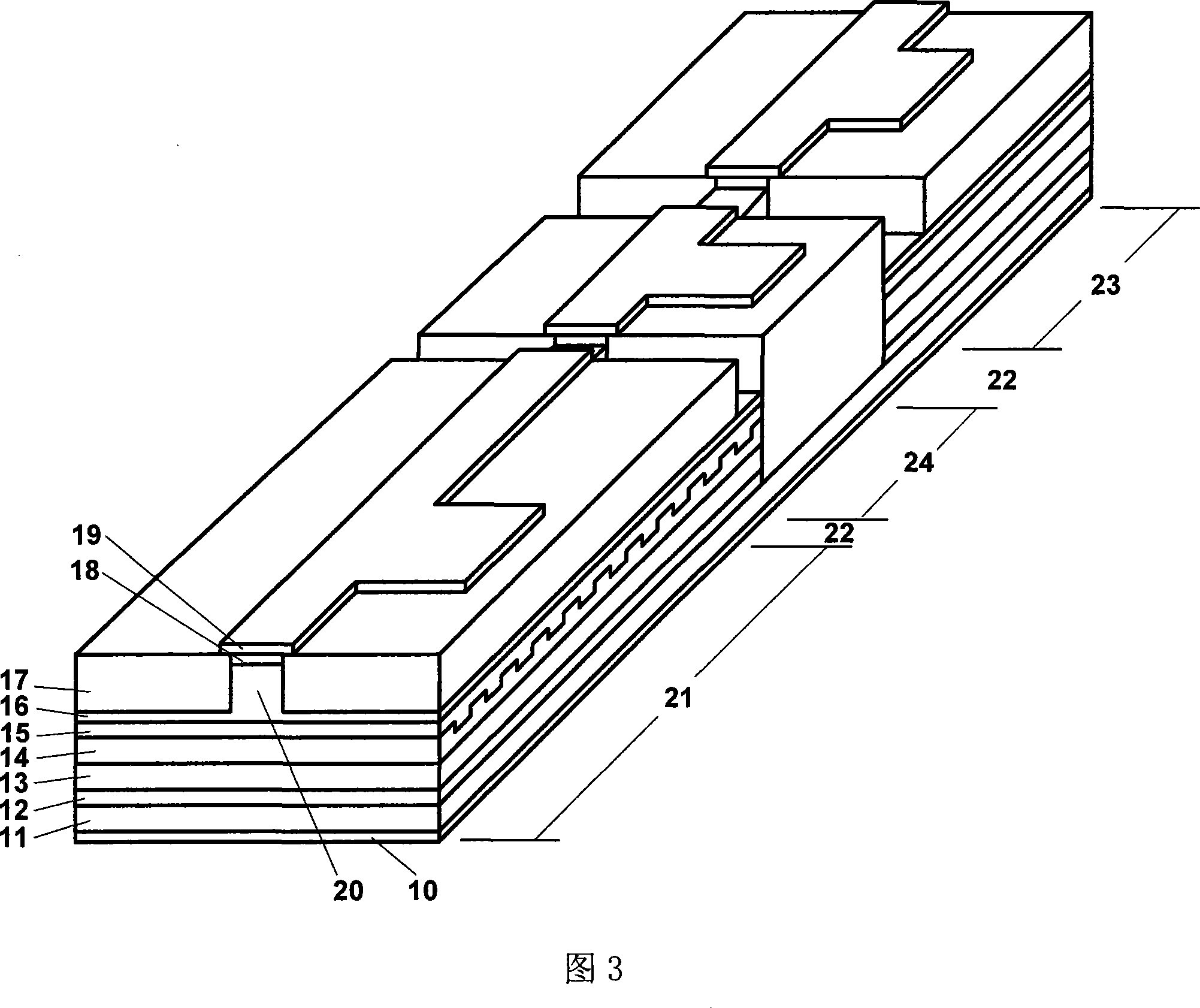

[0025]Referring to Figure 2, the working wavelength is in the 1550nm band, on the basis of direct modulation of DFB laser, using SOA four-wave mixing effect to generate high-frequency microwave InGaAsP / InP-based monolithic photonic integrated device.

[0026] The device integrates a DFB laser 21 and an SOA 23 on the same chip.

[0027] First, the epitaxial materials of the device are as follows. Through the MOCVD method, first epitaxially grow on the n-type substrate material once, and then grow the n-type InP lower cladding layer 11 (thickness 200nm, doping concentration about 1×10 18 cm -2 ), 100nm thick undoped lattice-matched InGaAsP waveguide layer 12 (photoluminescence wavelength 1.2μm), strained InGaAsP multiple quantum wells 13 (photoluminescence wavelength 1.52μm, 7 quantum wells: well width 8nm, 0.5% compressive strain, barrier InGaAsP grating material layer 14 with a width of 10 nm, a lattice matching material, and a photoluminescent wavelength of 1.2 μm) and a th...

Embodiment 2

[0031] Referring to Figure 3, the working wavelength is in the 1550nm band, on the basis of indirect modulation of DFB lasers, using the SOA four-wave mixing effect to generate high-frequency microwave InGaAsP / InP-based monolithic photonic integrated devices.

[0032] The device integrates a DFB laser 21, an EA modulator 24 and an SOA 23 on the same chip.

[0033] First, the epitaxial materials of the device are as follows. Through the MOCVD method, first epitaxially grow on the n-type substrate material once, and then grow the n-type InP lower cladding layer 11 (thickness 200nm, doping concentration about 1×10 18 cm -2 ), 100nm thick undoped lattice-matched InGaAsP waveguide layer 12 (photoluminescence wavelength 1.2μm), strained InGaAsP multiple quantum wells 13 (photoluminescence wavelength 1.52μm, 7 quantum wells: well width 8nm, 0.5% compressive strain, barrier InGaAsP grating material layer 14 with a width of 10 nm, a lattice matching material, and a photoluminescent w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap