Preparation method of calcium glycine

A technology of calcium glycinate and glycine, which is applied to the preparation of organic compounds, chemical instruments and methods, and preparation of cyanide reactions, etc., can solve the problems of limiting the application of calcium glycinate, uneven product quality, and different effects, and is easy to promote , stable product quality and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

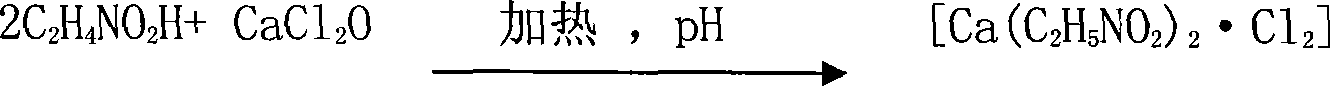

[0016] Embodiment 1: select glycine and calcium chloride as main raw materials, the reaction molar ratio of the two is 2: 1, first glycine is dissolved in water, and solid alkali is added to make it fully react, obtain glycine sodium salt after membrane separation, Dissolve calcium chloride in a solvent and add the aforementioned glycine sodium salt, adjust the pH to 5, heat to 80°C, react under stirring for 3 hours, evaporate and concentrate with a scraper film until the crystal film is deposited on the surface, take it out and store it at room temperature Slowly cool, then place in a refrigerator at 4°C for crystallization for 24 hours, place the purified crystals in a vacuum oven for drying, and make the chemical structural formula: [Ca(C 2 h 5 NO 2 ) 2 · Cl 2 ] of calcium glycinate products.

Embodiment 2

[0017] Embodiment 2: select glycine and calcium chloride as main raw materials, the reaction molar ratio of the two is 1: 1, first glycine is dissolved in water, and solid alkali is added to make it react fully, obtain glycine sodium salt after membrane separation, Dissolve calcium chloride in a solvent and add the above-mentioned glycine sodium salt, adjust the pH to 8, heat to 100°C, react for 4 hours under stirring, evaporate and concentrate with a scraper film until the crystal film is deposited on the surface, take it out and store it at room temperature Cool slowly, and then place it in a refrigerator at 7°C for crystallization for 20 hours, and place the purified crystals in a vacuum oven for drying to produce a calcium glycinate product.

Embodiment 3

[0018] Embodiment 3: select glycine and calcium chloride as main raw materials, the reaction molar ratio of the two is 3: 1, first glycine is dissolved in water, and solid alkali is added to make it react fully, obtain glycine sodium salt after membrane separation, Dissolve calcium chloride in a solvent and add the above-mentioned glycine sodium salt, adjust pH=3, heat to 60°C, react for 1 hour under stirring, evaporate and concentrate with a scraper film until the crystal film is deposited on the surface, take it out and store it at room temperature Cool slowly, and then place it in a refrigerator at 2°C for crystallization for 26 hours, and place the purified crystals in a vacuum oven for drying to produce a calcium glycinate product.

[0019] In the above-mentioned embodiments of the present invention, the calcium chloride and the solvent are mixed in a certain proportion, glycine sodium salt is added, and the pH value is adjusted. After heating and stirring, the mixture is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com