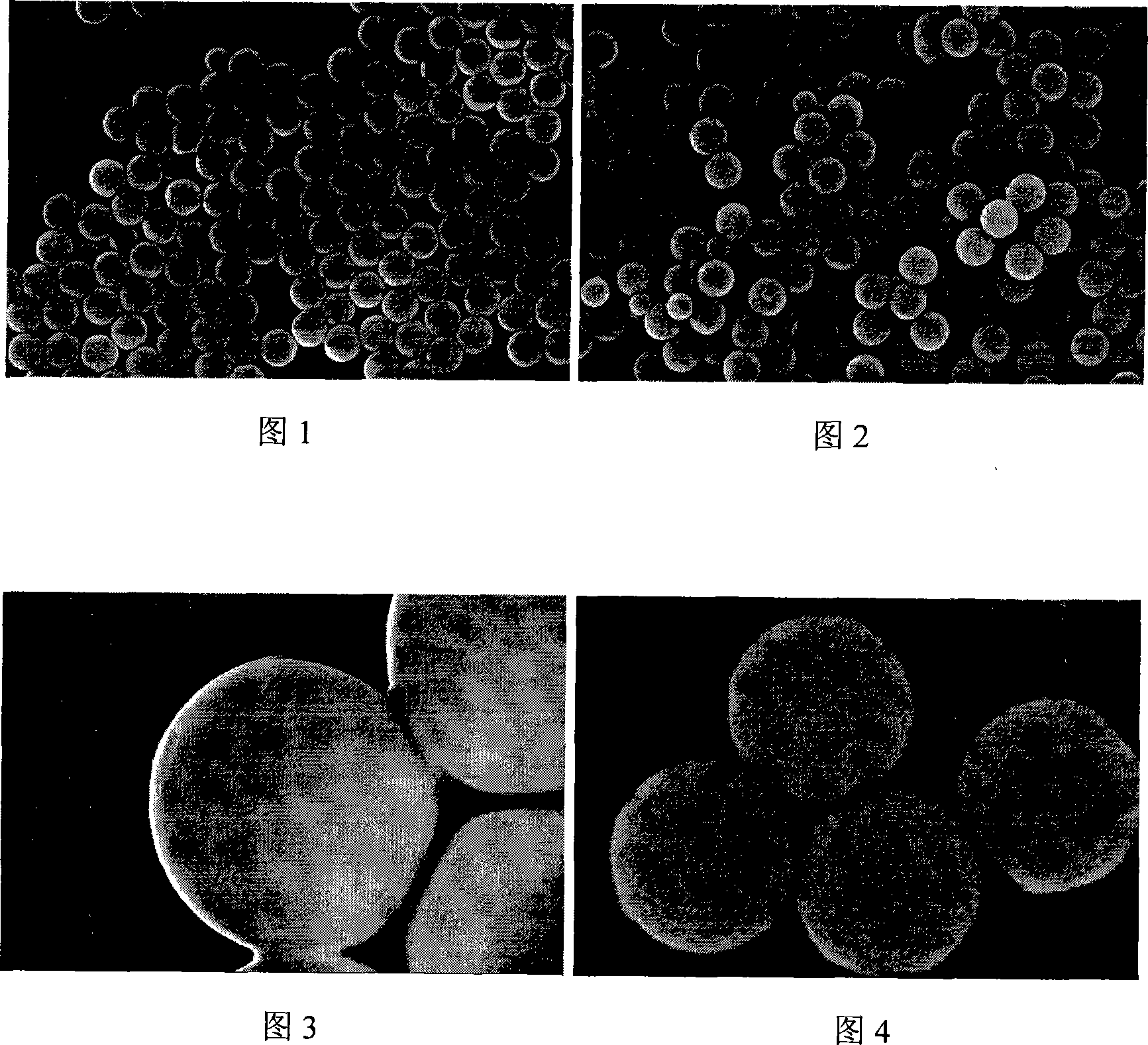

Method for preparing size monodispersed core-shell structural conductive polymer microspheres

A technology of conductive polymer and core-shell structure, applied in the direction of non-metallic conductors, organic material conductors, etc., can solve the problems of poor processability, insoluble and infusible, etc., and achieve extremely narrow particle size distribution, simple method, and shell thickness controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In the three-necked flask equipped with reflux condenser and mechanical stirrer, add monomer amount 10% stabilizer PVP, the medium is ethanol, pass N 2 Evacuate, heat up to the reaction temperature under stirring to dissolve PVP, add 1% BPO-dissolved styrene (St) at 80°C, and continue to pass N 2 2h, stirring at constant temperature for 9h to obtain a polymer dispersion. Centrifuge the emulsion with a low-speed centrifuge at 2500 rpm for 20 minutes, ultrasonically disperse the lower layer with denatured alcohol, then centrifuge, and wash repeatedly 5 times to wash away the floating stabilizers and oligomers on the surface of the microspheres. The microspheres were dried below 60°C. The obtained polymer microspheres had a particle size of 1.441 μm and a polydispersity index of 1.049.

[0028] Weigh 1 g of polystyrene monodisperse microspheres into a three-necked bottle, add 20 ml of deionized water, and disperse by ultrasonication for 30 minutes, then add 0.57 g of APS...

Embodiment 2

[0030] Same as in Example 1, the dosage of the stabilizer is 4.5%, the particle size of the obtained polymer microspheres is 2.491 μm, and the polydispersity index is 1.036.

Embodiment 3

[0032]Same as in Example 1, the dosage of the stabilizer is 3%, the particle size of the obtained polymer microspheres is 2.026 μm, and the polydispersity index is 1.061. The oxidizing agent is 0.675gKPS, and the amount of aniline is 0.220mL.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com