Multifunctional reactive cotton ultraviolet absorbent, synthetic method and use thereof

A multi-functional, synthetic method technology, applied in organic chemistry, textile and papermaking, fiber processing, etc., can solve the problems of reduced UV resistance, easy loss, disappearance, etc., and achieves the effect of good reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

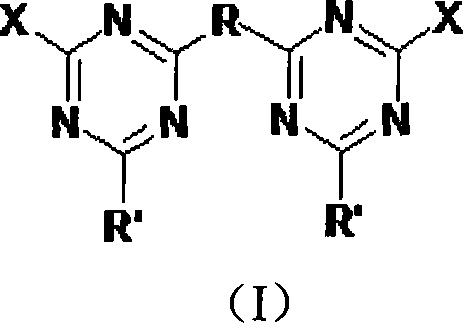

Method used

Image

Examples

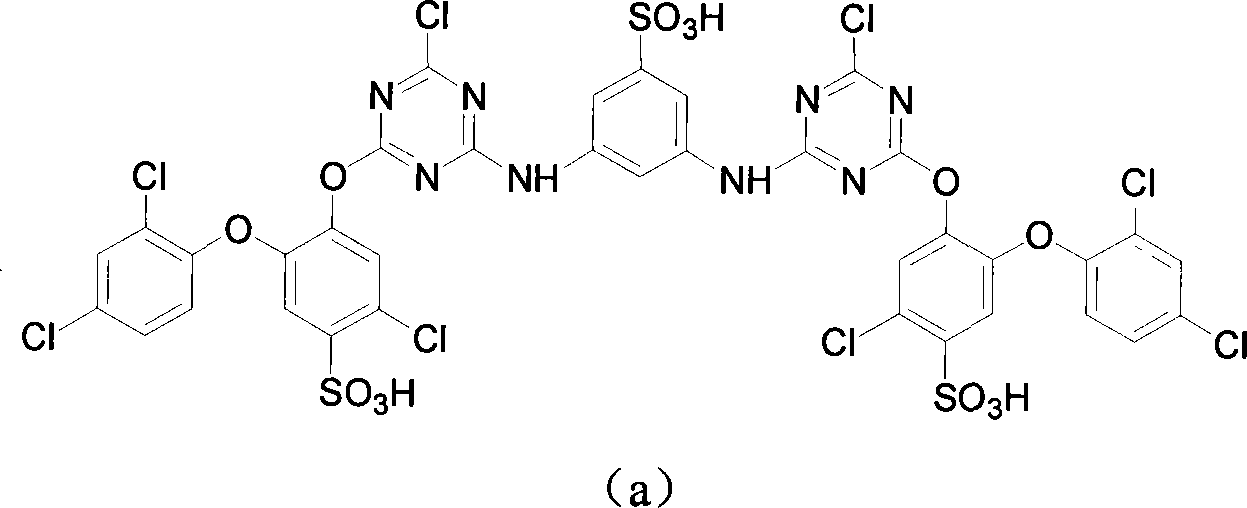

Embodiment 1

[0030] Weigh 30.6g of 23.5% 2,-dichloro-5-(2,4-dichlorophenyl)oxybenzenesulfonic acid aqueous solution and put it into a four-neck flask, and adjust the pH value to 6~6 with 30% NaOH aqueous solution. 8, then add 47g of water to the solution. Cool down to 0-5°C in an ice bath. Slowly add 5g of cyanuric chloride, and keep the reaction at 0-5°C for 90min. Then use 30% NaOH aqueous solution to adjust the pH value to 6.0-6.2, raise the temperature to 50°C, add 2.2g of 2,4-diaminobenzenesulfonic acid, and keep the temperature for 3 hours. During the reaction, use 10% Na 2 CO 3 The pH of the solution was adjusted so that it remained in the range of 5-6. Finally, a yellow-brown transparent solution is obtained, and compound a is obtained after separation and purification. Compound a is a multifunctional finishing agent for cotton with anti-ultraviolet properties and antibacterial properties. The resulting solution can be directly used for cotton fabric finishing without finishing...

Embodiment 2

[0033] This example is a research on the anti-ultraviolet and antibacterial performance of compound a, including determining the optimized finishing process, the test results of anti-ultraviolet performance and the test results of antibacterial performance.

[0034]For the optimized finishing process of compound a on pure cotton poplin, five factors and six levels of orthogonal experiments were used to finally obtain the optimized finishing process as follows: bath ratio 1:15, put finishing agent and cotton cloth at room temperature, and the amount of finishing agent was fabric weight 1 to 10% of the solution, heat up to 65°C, add 40g / L sodium sulfate, keep warm for 40min, then add 30g / L soda ash, heat up to 90°C, keep warm for 25min, wash once with hot water, rinse with cold water, and dry.

[0035] Under the optimized finishing process conditions, the light brown viscous liquid obtained in Example 1 is used to directly carry out anti-ultraviolet finishing to the pure cotton p...

Embodiment 3

[0042] Add 4.3g of sodium bicarbonate into 80g of ice water, after completely dissolved, slowly add 7.8g of 2,2,6,6-tetramethylpiperidinol, and stir until the solution becomes clear. Then add 9.2 g of cyanuric chloride several times in small batches, and keep warm at 0-5°C for 90 minutes. After the reaction is completed, adjust the pH to 6-6.2 with a certain concentration of sodium hydroxide solution, then raise the temperature to 40°C, add 4.7g of 2,4-diaminobenzenesulfonic acid dropwise, and keep the reaction for 3 hours. During the reaction process, adjust the pH to 5-6 with a certain concentration of sodium hydroxide solution every half hour. Finally, 16 g of p-(β-sulfate ethylsulfone) aniline was slowly added, and stirred at 85-90° C. for 3 hours. After the reaction, a light brown solution is obtained, which is separated by filtration and dried to obtain compound b, which is a multifunctional finishing agent with both anti-ultraviolet and light-stabilizing properties. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com