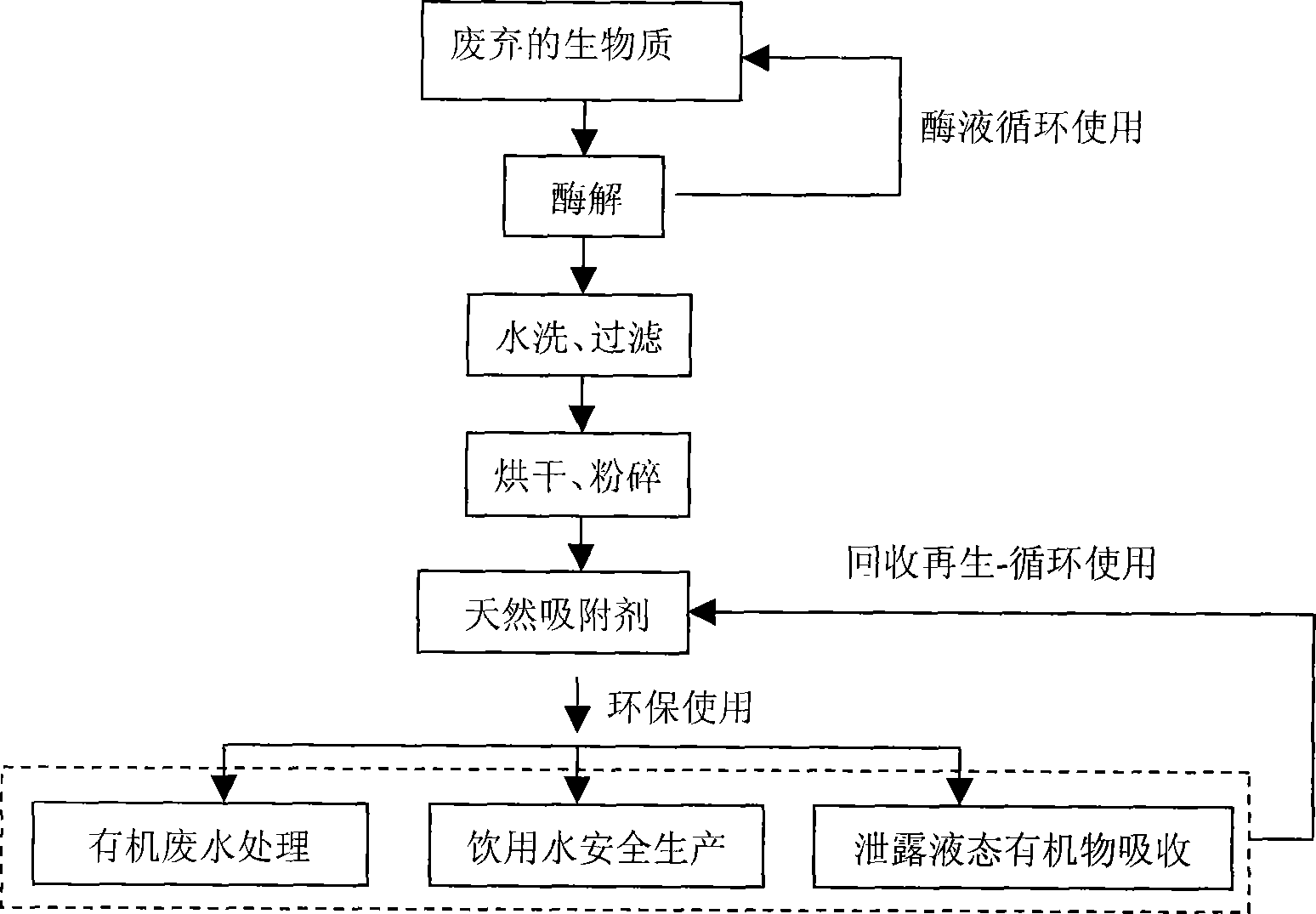

Method and use for preparing natural adsorption agent by zymolysis

An adsorbent, enzymatic hydrolysis technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, other chemical processes, etc. Non-toxic and harmless, environmentally friendly production process, and the effect of large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Using discarded tomato peels, apple peels, potato peels and other plant peels as raw materials, add a 1:1 mixed solution of 0.5mg / L cellulase and 0.5mg / L pectinase in the fermentation reactor, at 0.01mol / L Under the buffer solution of L acetic acid / sodium acetate solution (pH=5), the fermentation temperature is controlled at 30° C. and the stirring speed is 20 r / min, and the biomass is enzymatically hydrolyzed for 10 days. Add 100 mL of enzyme solution per gram of biomass raw material. Dissolving and removing polar components such as cellulose and pectin in biomass raw materials; the remaining components are mainly non-polar components, including aromatic plant lignin and fatty plant cutin; the obtained residue is processed After washing, filtering, drying and crushing, the natural adsorbent NS-1 is obtained.

Embodiment 2

[0027] Using discarded tomato peels, apple peels, potato peels and other plant peels as raw materials, add a 1:1 mixture of 2mg / L cellulase and 2mg / L pectinase in the fermentation reactor, and add 2mg / L of pectinase at 0.05mol / L Under the buffer solution of citric acid / sodium citrate (pH=3), the fermentation temperature was controlled at 40° C. and the stirring speed was 50 r / min, and the biomass was enzymatically hydrolyzed for 5 days. Add 50 mL of enzyme solution per gram of biomass raw material. Dissolving and removing polar components such as cellulose and pectin in biomass raw materials; the remaining components are mainly non-polar components, including aromatic plant lignin and fatty plant cutin; the obtained residue is processed After washing, filtering, drying and crushing, the natural adsorbent NS-2 is obtained.

Embodiment 3

[0029]Using discarded tomato peels, apple peels, potato peels and other plant peels as raw materials, add a 1:1 mixture of 8mg / L cellulase and 8mg / L pectinase in the fermentation reactor, and add Under acetic acid / sodium acetate solution or 0.5 mol / L citric acid / sodium citrate buffer solution (pH=3), the fermentation temperature was controlled at 50° C. and the stirring speed was 200 r / min, and the biomass was enzymatically hydrolyzed for 1 day. Add 10 mL of enzyme solution per gram of biomass raw material. Dissolving and removing polar components such as cellulose and pectin in biomass raw materials; the remaining components are mainly non-polar components, including aromatic plant lignin and fatty plant cutin; the obtained residue is processed After washing, filtering, drying and crushing, the natural adsorbent NS-3 is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Absorption | aaaaa | aaaaa |

| Maximum adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com