Integrated utilization method for byproduct of vanillin production

A by-product, vanillin technology, applied in the direction of organic chemistry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

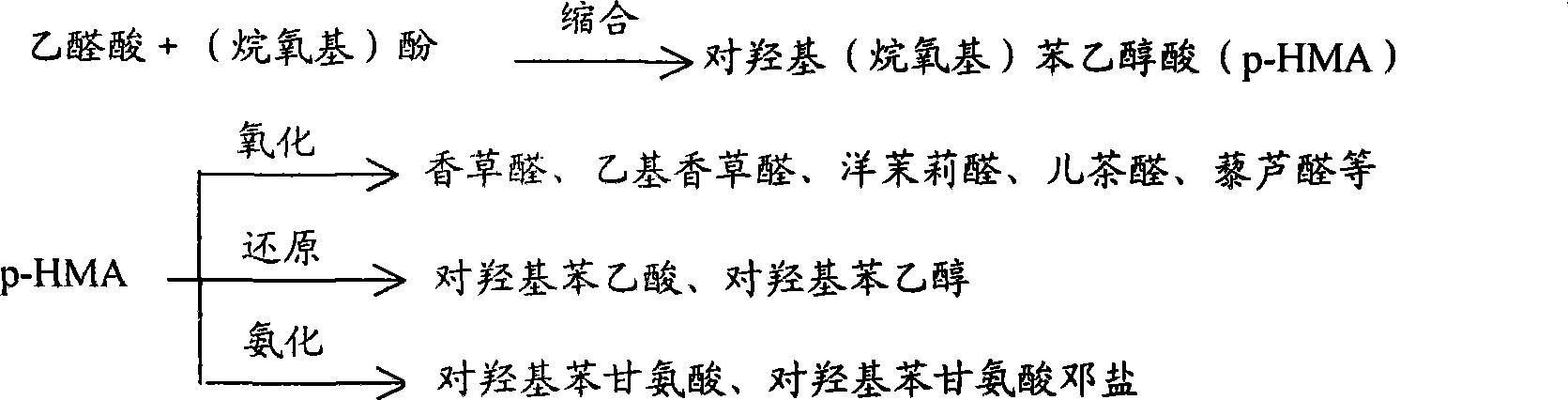

Method used

Image

Examples

Embodiment 1

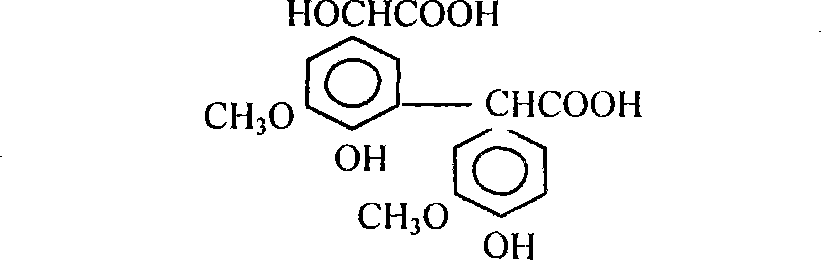

[0012] 156.6 g of industrial guaiacol (1.2 mol) with a content of 95% was dissolved in 1200 ml of 4% sodium hydroxide solution to obtain a light red sodium guaiacol solution. 1000ml of 10% sodium carbonate solution was added into 222g of 40% glyoxylic acid solution (1.2mol) under stirring to obtain light yellow sodium glyoxylate solution. Use a 3000ml four-necked bottle equipped with a stirrer, a thermometer and a dropping funnel as the reactor, first add the sodium guaiacol solution, then add the sodium glyoxylate solution dropwise at 15-25°C under stirring, and complete the addition in about 8 hours , Then continue to stir and react for about 8 hours to make all sodium glyoxylate in the solution convert. The total volume of the reaction mother liquor is about 2400ml, and liquid chromatography analysis contains 190g (0.96mol) of 3-methoxyl-4-p-hydroxymandelic acid and 45.4g of 3-methoxyl-4-p-hydroxymandelic acid dimer (0.12 mol). Concentrate the reaction solution in vacuo t...

Embodiment 2

[0014] Add 45.4g (0.12mol) of 3-methoxy-4-p-hydroxymandelic acid dimer into a 250ml four-necked bottle equipped with a stirrer, a thermometer and a dropping funnel, and add 37% formaldehyde solution under stirring 19.5 g (0.24 mol). Heat to 65°C with an electric heating mantle, add dropwise 10% hydrochloric acid solution, control the pH of the solution to 1.5-2.5, and stop the condensation reaction after reacting for 3 hours. Concentrate in vacuo, and remove the upper layer of water after cooling to obtain 48.1 g of modified phenolic resin.

Embodiment 3

[0016] Add 45.4g (0.12mol) of 3-methoxy-4-p-hydroxymandelic acid dimer into a 250ml four-necked bottle equipped with a stirrer, a thermometer and a dropping funnel, and add epichlorohydrin under stirring 33.6 g (0.36 mol). 25ml of 30% sodium hydroxide solution was added dropwise, and the temperature was controlled at 75°C. After the alkali solution was added dropwise, the reflux reaction was continued for 1.5h, and then the condensation reaction was stopped by cooling. Separate the organic phase by extracting three times with 150 ml of benzene, and wash the organic phase with warm water. Excess epichlorohydrin was recovered by distillation to obtain 50.1 g of modified epoxy resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com