Core-shell type lightweight broad-band composite wave-absorbing material and preparation method thereof

A composite wave absorbing material and composite material technology are applied in the field of core-shell type light-weight broadband composite wave absorbing materials and their preparation, which can solve the problem that the effective absorption frequency band of wave absorbing coatings is not wide, the amount of carbonyl iron powder is large, and the wave absorbing performance is poor. Not ideal, etc., to avoid military strikes, prevent harm to the human body, and achieve the effect of small density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] 1. Preparation of CIP / PMMA composites

[0018] Take 10 grams of carbonyl iron powder (CIP), add carbonyl iron powder (CIP) to 50 ml of ethyl acetate solution containing γ-aminopropyltriethoxysilane coupling agent, and stir vigorously to obtain silane coupling agent treatment Processed CIP; add the treated CIP to ethanol aqueous solution, ultrasonically disperse and stir, then add methyl methacrylate, when the temperature rises to 65°C, dropwise add ammonium persulfate aqueous solution to initiate the reaction (2h drops), and keep warm for 1h After the reaction was over, the obtained solid was washed with hydrochloric acid and distilled water, dried in an oven at 80°C for 12 hours, ground for 15 minutes, and magnetically separated to obtain a CIP / PMMA composite material, so that the mass percentage of CIP and PMMA was 33:67.

[0019] 2. Preparation of CIP / PMMA / PANI double-layer coated core-shell composites

[0020] The CIP / PMMA composite material that makes in the 1st s...

Embodiment 2

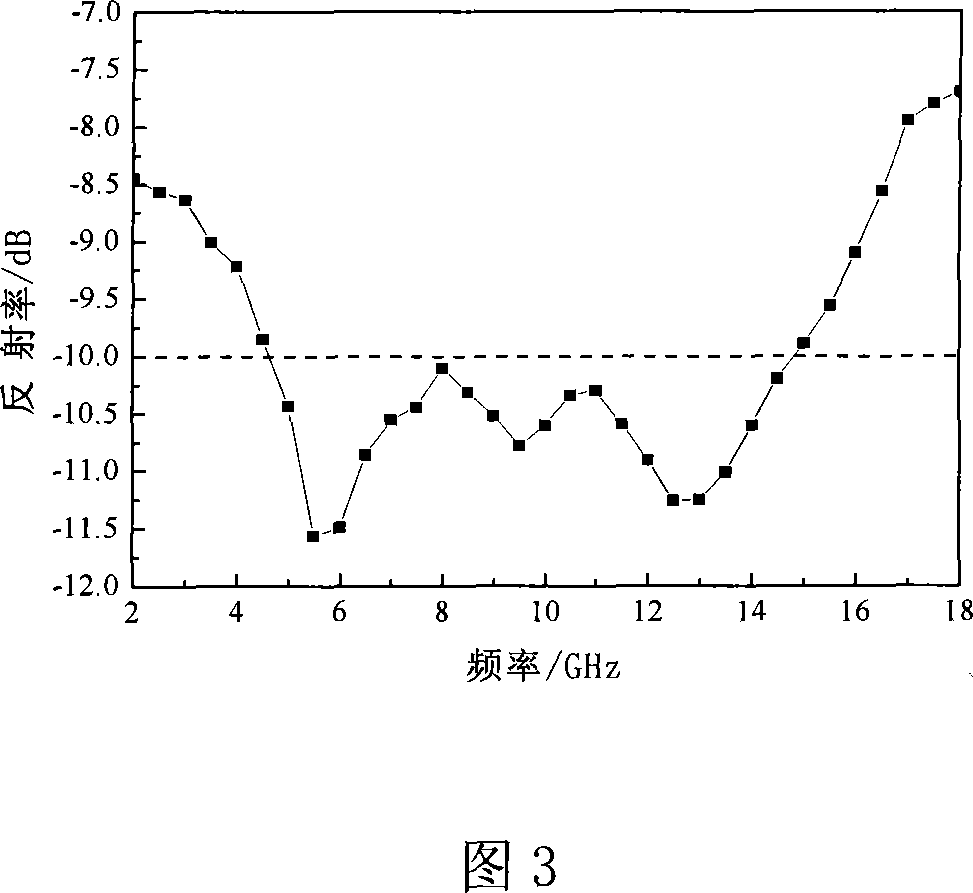

[0025] The mass percentage of present embodiment CIP and PMMA is 40: 60, the mass percentage of CIP / PMMA and PANI is 70: 30, the mass percentage of CIP / PMMA / PANI and paraffin is 50: 50; In the preparation of CIP / PMMA composite material During the process, after adding methyl methacrylate, when the temperature rises to 65-70°C, ammonium persulfate is added dropwise; the aqueous solution initiates the reaction, and the reaction ends after 1-1.5 hours of heat preservation, and the obtained solid is washed with hydrochloric acid and distilled water and placed in 80 Dry in an oven at ~85°C for 10-12 hours, grind for 15-20 minutes, and magnetically separate to obtain the CIP / PMMA composite material. During the preparation process of CIP / PMMA / PANI double-layer coated core-shell composite material, ammonium persulfate aqueous solution was added dropwise, the temperature was controlled at 8-10°C, after the reaction was completed, it was filtered and washed with absolute ethanol and dist...

Embodiment 3

[0027] In this embodiment, the mass percent of CIP and PMMA is 35:65, the mass percent of CIP / PMMA and PANI is 65:35, the mass percent of CIP / PMMA / PANI and paraffin is 40:60, other process methods and parameters and embodiments 2 is the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com