Self-medium coupled microbe fuel battery for single room micro filtering

A technology of fuel cells and microfiltration membranes, applied in the direction of biochemical fuel cells, etc., can solve problems such as theoretical and technical difficulties that have not been well resolved, increase COD, bacteria difficulties, etc., and achieve high sewage COD removal rate and power generation. Low net energy loss, space-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

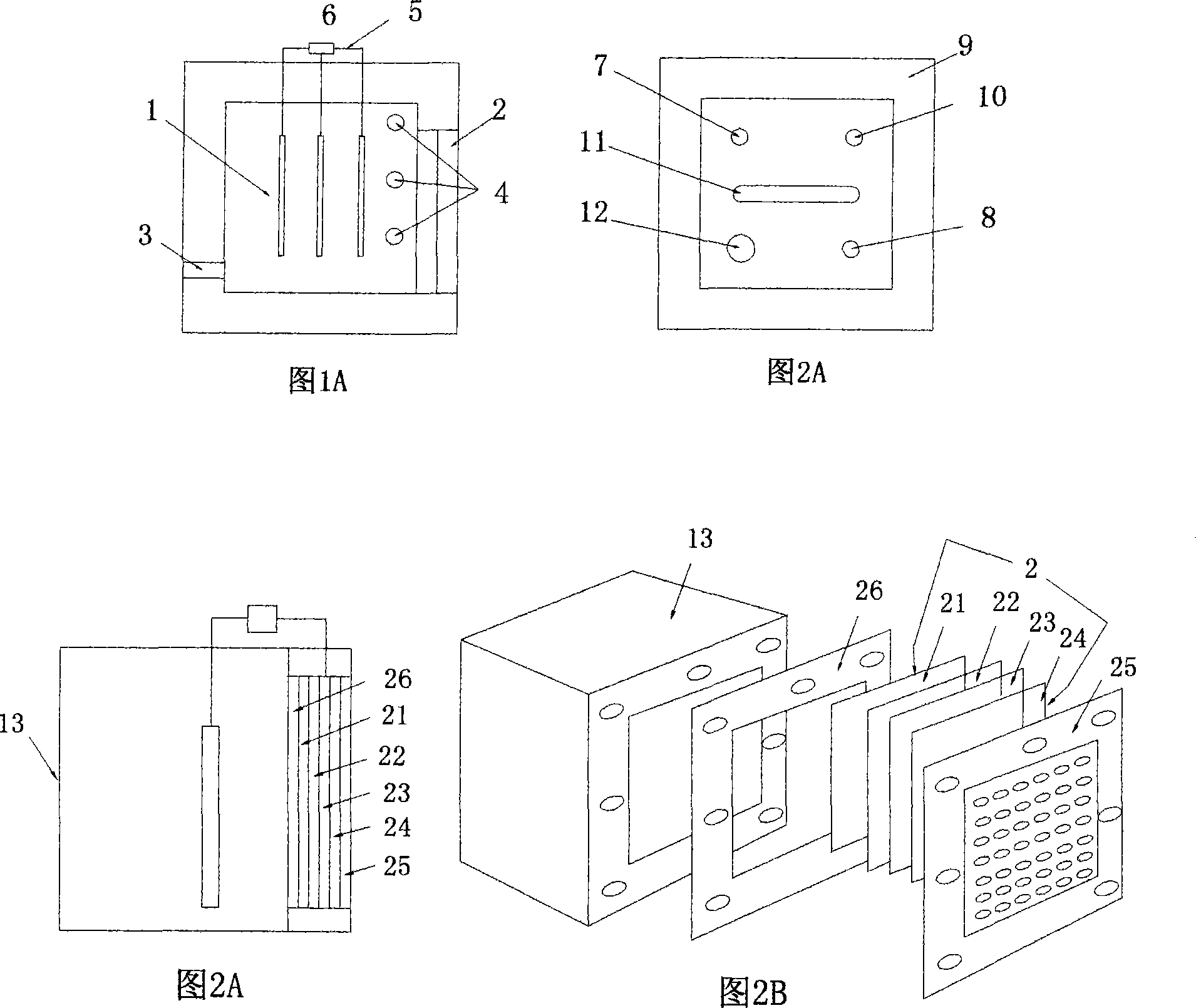

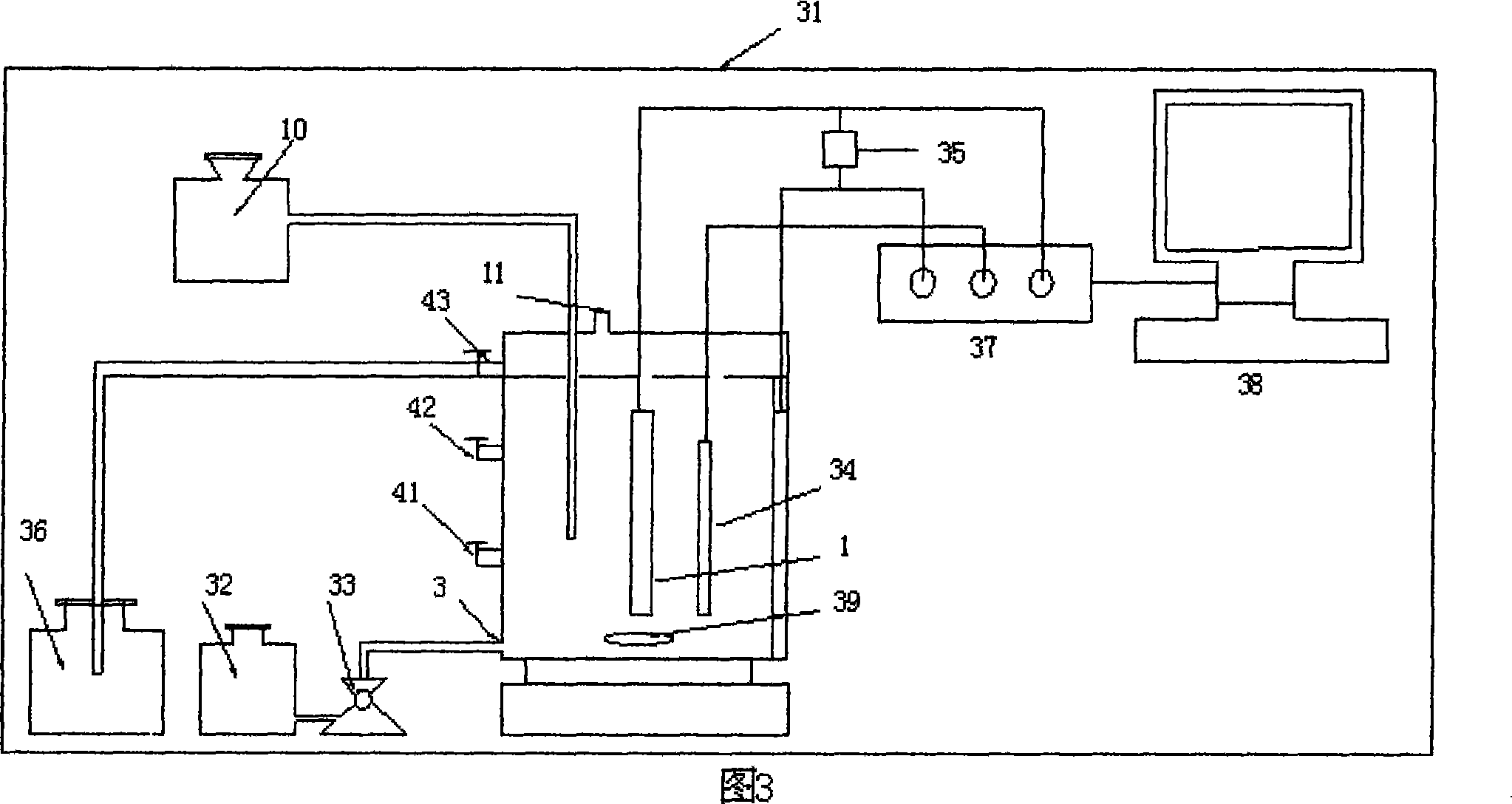

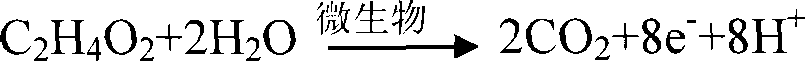

Method used

Image

Examples

Embodiment 1

[0049] When anaerobic sludge is inoculated, glucose is used as the fuel substrate, and a 500-ohm external resistance is connected to operate the invention, a complete operation cycle only takes 3 days. Since the start, there will be a higher than The current generation of 40 times the background value can repeatedly generate a stable current of about 1.2mA from the third cycle, which lasts for more than three days, and the recovery time between cycles is short, which can quickly charge and discharge. At the same time, the COD removal rate is as high as 90%. All the above are the results obtained without any performance optimization in the present invention, and there is still a lot of room for performance improvement.

Embodiment 2

[0051] Inoculate with anaerobic sludge, externally connect 500 ohm resistance, by comparatively researching the MFC operation results after no membrane, proton exchange membrane, ultrafiltration membrane and the microporous membrane of the present invention and cathode are integrated, it is shown that the present invention can The maximum voltage of 0.59v is obtained in three cycles, which is much higher than 0.45v of proton exchange membrane and 0.18v of ultrafiltration membrane, and even higher than 0.57v of membraneless cathode. The COD removal rate is also as high as 90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com