Netted Cu antimicrobial filtering metallic material and preparation thereof

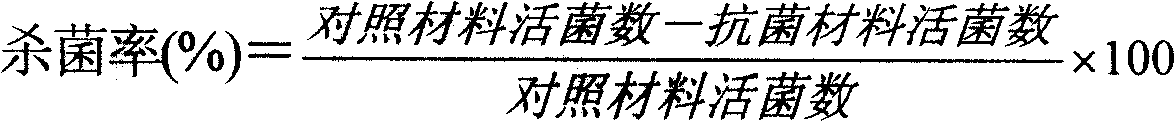

A technology for filtering metal and mesh, which is applied in the field of high-porosity reticulated Cu antibacterial filter metal material and its preparation, can solve the problems of insufficient copper intake, poor beer taste, energy consumption, etc., and achieves a simple and easy preparation method line, increased intake, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

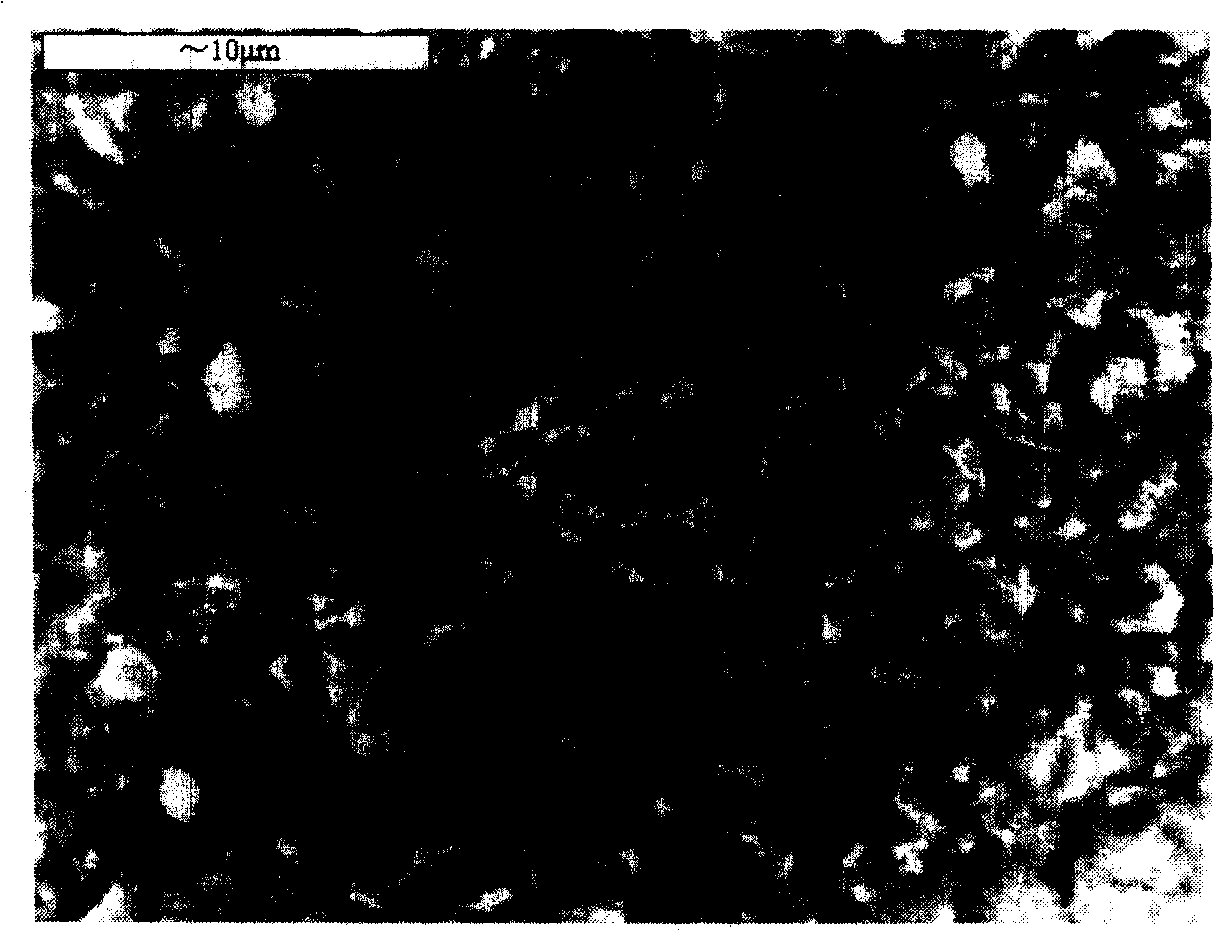

Image

Examples

Embodiment 1

[0028] Foam sponge material (pore diameter is about 550 microns) is first sensitized, and the specific process and process parameter range of sensitization are: put the sample into sensitization solution (stannous chloride 20g / L, mass concentration 37% Hydrochloric acid 40ml / L and distilled water balance), soak for 3 minutes, remove and wash with water, and then immerse in a solution containing an oxidant at room temperature (silver nitrate 1.5g / L, add ammonia water to the solution transparency and distilled water balance) and soak for 10 minutes Form an active metal layer on the surface of the substrate, then take 200ml of electroless copper plating solution and add water to dilute it to 1L, soak the above-mentioned treated material in it for 20 seconds (to prevent the activation solution remaining on the surface of the sample from being brought into the electroless plating solution ), directly into the chemical copper plating solution at room temperature and soaked for 5 minu...

Embodiment 2

[0063] The difference from Example 1 is:

[0064] Foam sponge material (pore size is about 550 microns) is first sensitized, and at room temperature, the sample is put into sensitized solution (50ml / L of hydrochloric acid 50ml / L and distilled water surplus of stannous chloride 10g / L, mass concentration 37%) After soaking for 5 minutes, take it out and wash it, and then immerse it in a solution containing an oxidant at room temperature (silver nitrate 2.0g / L, add ammonia water to the transparent solution and the remainder of distilled water) and soak for 15 minutes to form an active metal layer on the surface of the substrate, and then take it out Dilute 200ml of electroless copper plating solution with water to 1L, soak the above-mentioned treated material in it for 30 seconds for a short time, then soak it in the electroless copper plating solution for 8 minutes at room temperature without washing with water, and plate copper to make the foam sponge material To obtain electri...

Embodiment 3

[0068] The difference from Example 1 is:

[0069]Foam sponge material (pore diameter is about 550 microns) is first sensitized, and at room temperature the sample is put into the sensitization solution (hydrochloric acid 40ml / L and distilled water surplus of stannous chloride 30g / L, mass concentration 37%) After soaking for 4 minutes, take it out and wash it, and then immerse it in a solution containing oxidant (silver nitrate 1.5g / L, ammonia water added to the solution transparency and distilled water remainder) at room temperature and soak for 20 minutes to form an active metal layer on the surface of the substrate, and then take it out Dilute 200ml of electroless copper plating solution with water to 1L, soak the above-mentioned treated material in it for 10 seconds, then soak in the electroless copper plating solution for 10 minutes at room temperature without washing with water, and then plate copper to make the foam sponge material obtain electrical conductivity. The com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com