Hydrotalcite/polyalcohol composite self-supporting thin film and manufacture method thereof

A technology of self-supporting film and composite film, which is applied in the field of hydrotalcite/polymer composite self-supporting film and its preparation, which can solve the problems of fragility, difficulty in precise control, and unstable existence of the film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

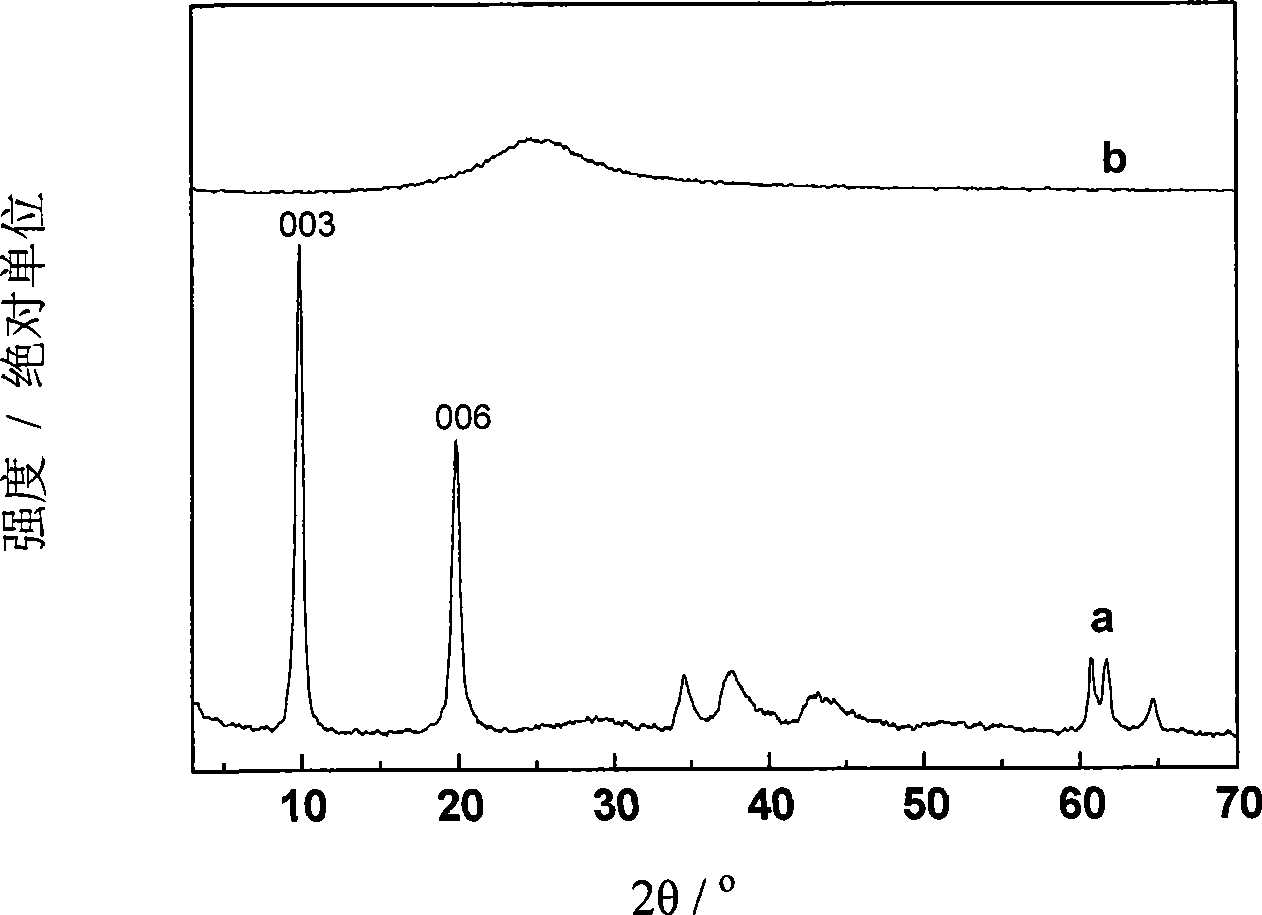

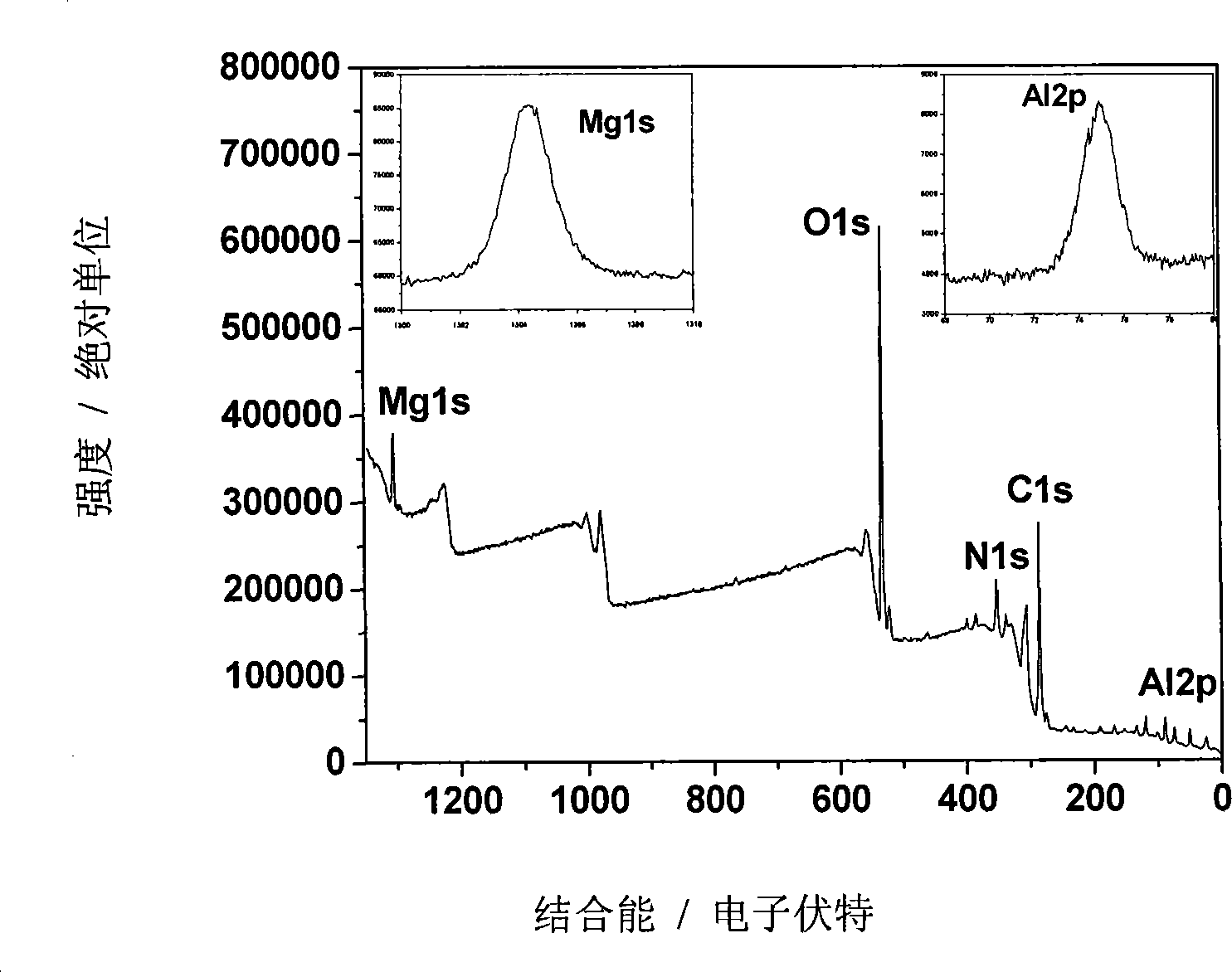

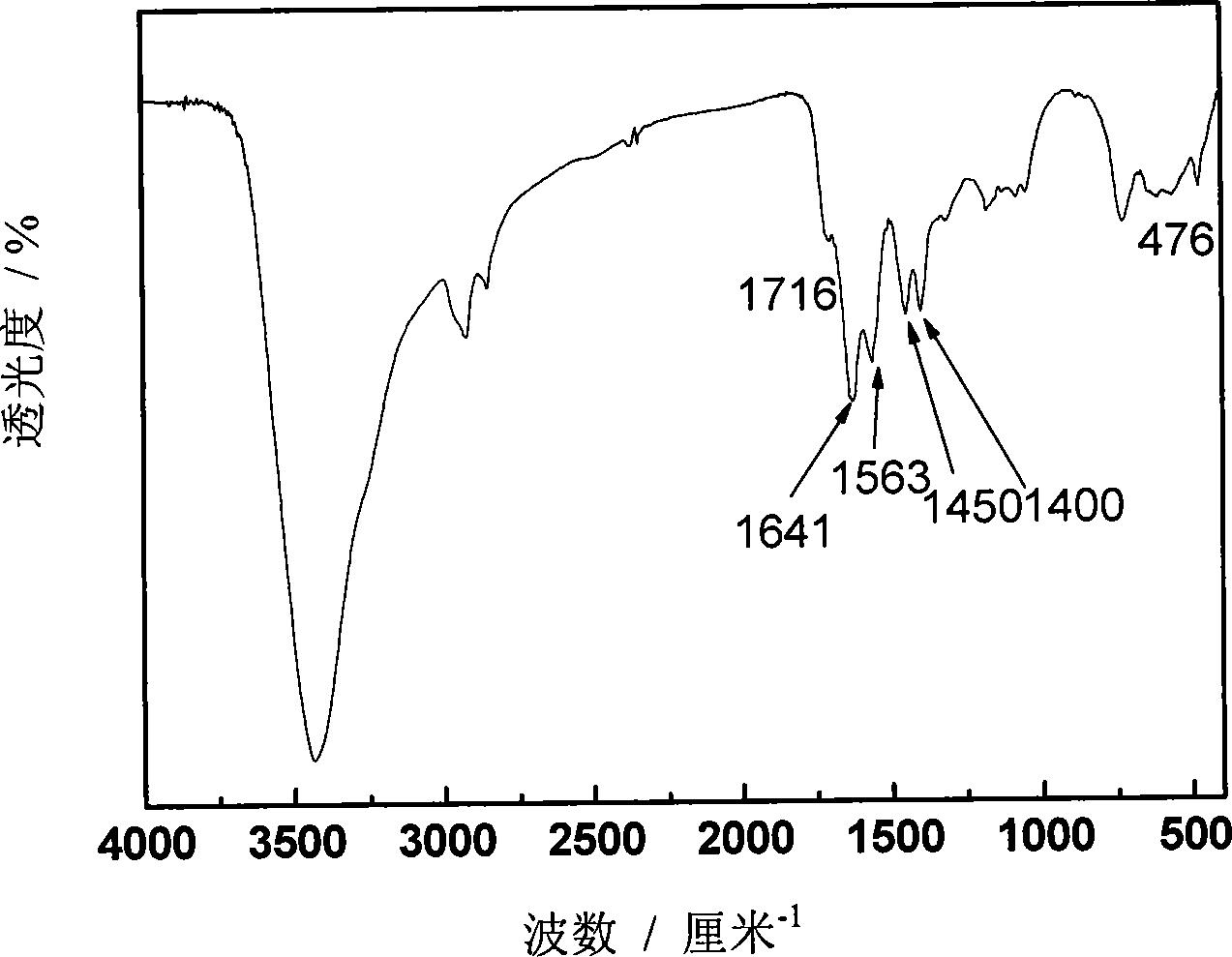

[0029] Weigh 15.384g Mg(NO 3 ) 2 ·6H 2 O and 11.253gAl(NO 3 ) 3 9H 2 O dissolved in 50 mL to remove CO 2 In water, prepare a mixed salt solution, take another 6.84g NaOH and dissolve it in 50mL to remove CO 2 In water, quickly pour the alkali solution and the mixed salt solution into a fully back-mixed rotating liquid film reactor to react for 1 minute, and the obtained slurry was hydrothermally crystallized at 120° C. for 8 hours, and the obtained sample was washed to pH=7. The obtained sample was dried at 60 °C for 24 h and ground to obtain magnesium aluminum hydrotalcite (Mg 2 Al-NO 3 LDHs) powder; take 0.1g Mg 2 Al-NO 3 -Add LDHs powder into 100mL formamide solution, stir and react for 1 hour to obtain a clear and transparent sol with a concentration of 1.0g / L. Get 1 drop of sol to drop on the ground glass slide and carry out X-ray diffraction analysis, XRD spectrogram ( figure 1 ) shows that the (003), (006) and other layered structure characteristic diffractio...

Embodiment 2

[0039] Weigh 23.220g Co(NO 3 ) 2 ·6H 2 O and 10.010g Al(NO 3 ) 3 9H 2 O dissolved in 100mL to remove CO 2 In water, prepare a mixed salt solution, take another 8.117g NaOH and dissolve it in 100mL to remove CO 2 In water, quickly pour the alkali solution and the mixed salt solution into a fully back-mixed rotating liquid film reactor for 1 minute reaction, the resulting slurry was hydrothermally crystallized at 140° C. for 10 hours, and the obtained sample was washed to pH=7.5. The obtained sample was dried at 80 °C for 24 h and ground to obtain cobalt aluminum hydrotalcite (Co 3 Al-NO 3 LDHs) powder; take 0.2g Co 3 Al-NO 3 LDHs powder was added into 100mL formamide solution, stirred and reacted for 2 hours to obtain a clear and transparent sol with a concentration of 2.0g / L. Two drops of the sol were put on a ground glass sheet for X-ray diffraction analysis. The XRD spectrum showed that the (003), (006) and other layered structure characteristic diffraction peaks o...

Embodiment 3

[0044] Weigh 34.896g Ni(NO 3 ) 2 ·6H 2 O and 11.253gAl(NO 3 ) 3 9H 2 O dissolved in 50 mL to remove CO 2 In water, prepare a mixed salt solution, take another 11.410g NaOH and dissolve it in 50mL to remove CO 2 In water, the alkali solution and the mixed salt solution were quickly poured into a fully back-mixed rotating liquid film reactor for 1 minute of reaction, and the obtained slurry was hydrothermally crystallized at 160° C. for 16 hours, and the obtained sample was washed to pH=7. The resulting sample was dried at 70 °C for 20 h and ground to obtain nickel aluminum hydrotalcite (Ni 4 Al-NO 3 LDHs) powder; take 0.3g Ni 4 Al-NO 3 LDHs powder was added into 100mL formamide solution, stirred and reacted for 3 hours to obtain a clear and transparent sol with a concentration of 3.0g / L. Take 1 drop of sol and put it on a ground glass sheet for X-ray diffraction analysis. The XRD spectrum shows that the (003), (006) and other layered structure characteristic diffracti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com