Method for intensifying light absorption of thin-film solar cell

A thin film and performance technology, applied in the field of solar photovoltaic equipment, can solve the problems of poor controllability and repeatability of roughness, increased absorption of incident light, poor electrical conductivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

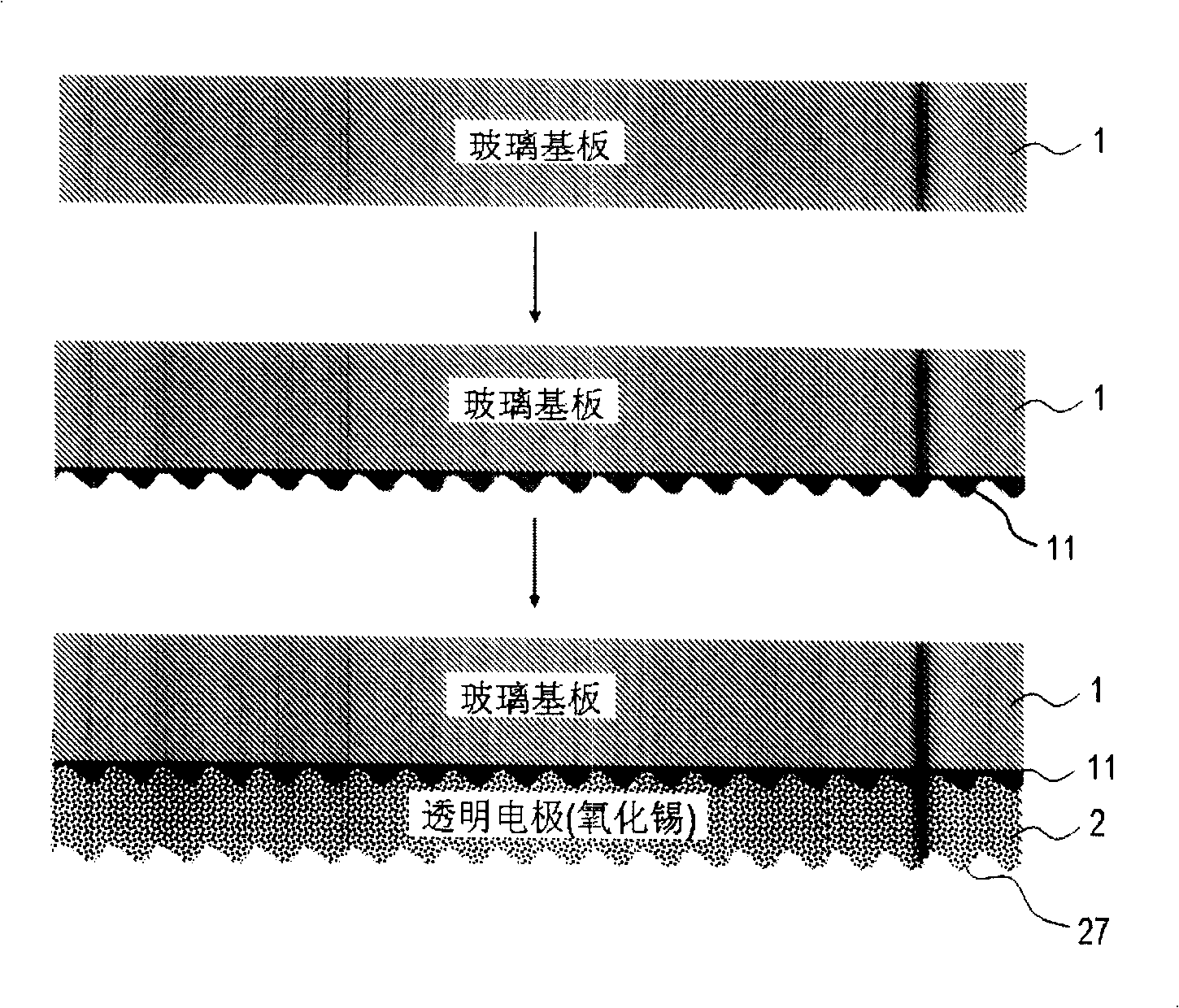

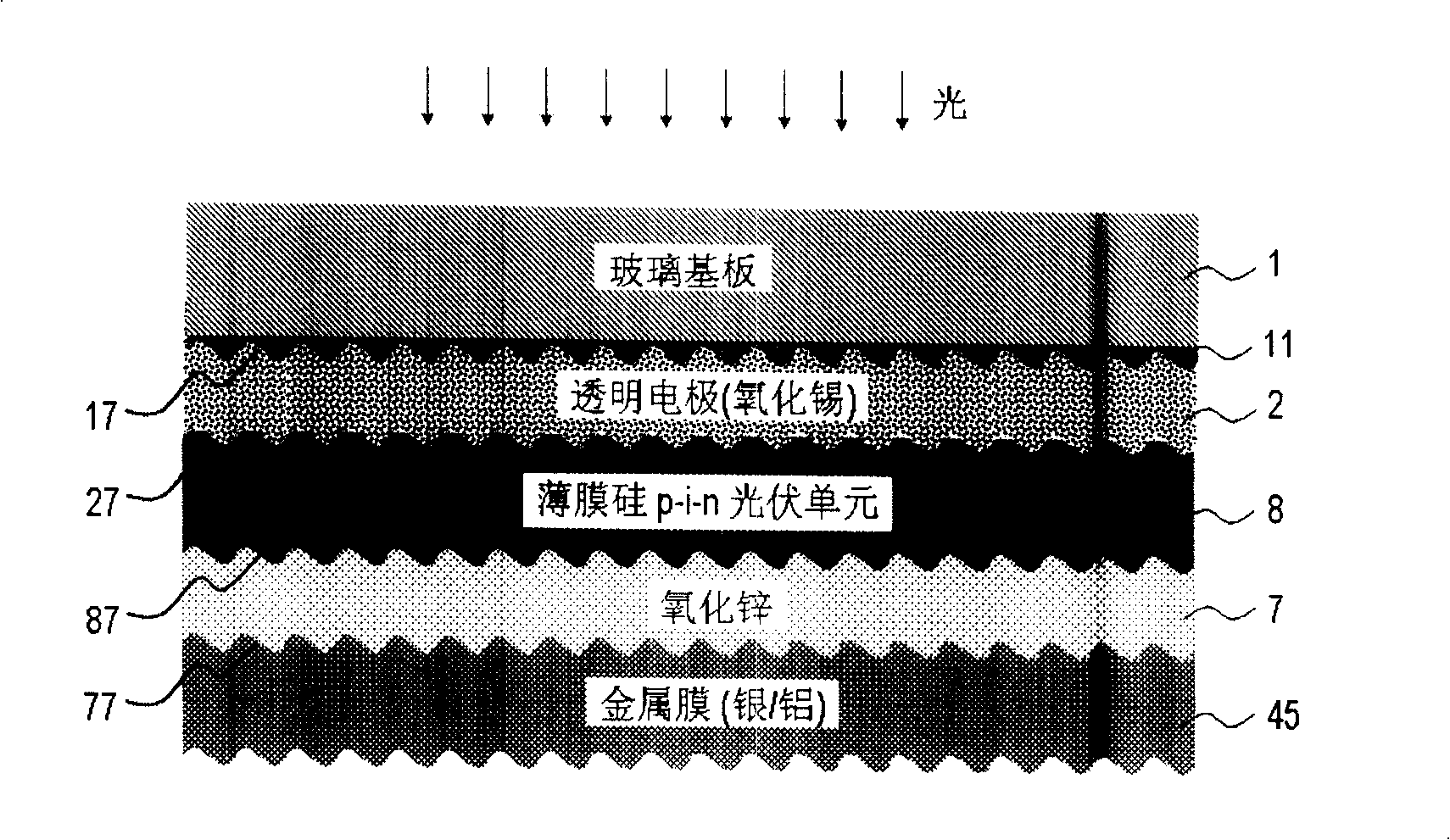

[0013] Such as figure 1 As shown, the first step of the present invention is to clean the flat glass plate 1, and then use sol-gel deposition method (sol-gel) to coat glass balls on the surface of the glass substrate. The specific method is to immerse the glass plate in a sol containing glass beads and adhesives, and constantly stir the sol or move the substrate itself, so that the glass beads evenly adhere to the surface of the glass substrate, and then the glass The substrate is taken out from the sol stagnant body, and heat-treated at a temperature not higher than 500° C. to solidify the adhesive, so that the glass beads are firmly attached to the glass substrate, forming a film layer 11 with an undulating structure. Thereafter, a transparent front electrode 2 (TCO), such as tin oxide or zinc oxide, is deposited on the surface layer 11 so that its surface 27 has a surface roughness similar to that of the glass surface layer 11 or to a greater extent. The average undulation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com