Seaweed plants and preparation of crust amine combined biological adsorption material and applications thereof

A biological adsorption, chitosan technology, applied in chemical instruments and methods, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of difficult to deal with harmful heavy metal pollution, secondary pollution, etc., to achieve convenient separation , convenient source, good selection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

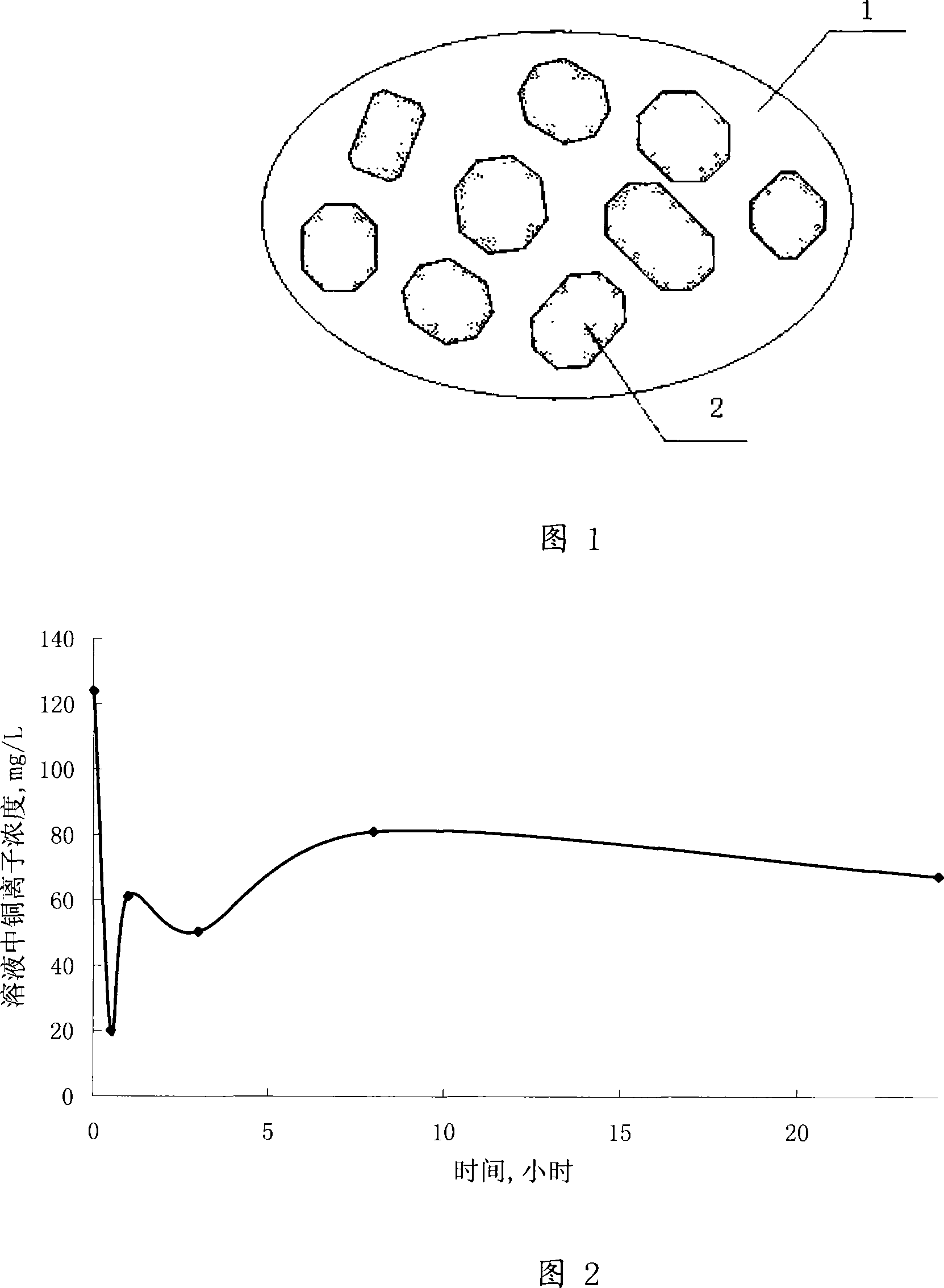

[0030] Embodiment one, the processing technology of brown algae biosorbent material of present embodiment comprises the following steps:

[0031] A, soaking brown algae plants with a concentration of 1% hydrochloric acid solution, and processing the brown algae plants after hydrochloric acid treatment into powder, the number of parts of the hydrochloric acid solution is 5 times the number of seaweed plants;

[0032] B. Mix chitosan with dilute acid solution. According to the weight ratio, chitosan accounts for 0.5 part in every 100 parts, and the rest is the parts of dilute acid solution. After mixing, chitosan dilute acid solution is formed. Dilute chitosan acid The solution is mixed with the powdered seaweed plant in step A and then extruded under pressure. In proportion by weight, every 100 parts of the chitosan dilute acid solution accounts for 99.5 parts, and the rest is the parts of the seaweed plant. The dilute acid solution is the concentration 0.5% acetic acid aqueous...

Embodiment 2

[0036] Embodiment two, the processing technology of seaweed biosorbent material of this embodiment comprises the following steps:

[0037] A, soaking the seaweed plants with a concentration of 10% hydrochloric acid solution, and processing the seaweed plants after the hydrochloric acid treatment into powder, in proportion by weight, the number of parts of the hydrochloric acid solution is 20 times the number of parts of the seaweed plants;

[0038] B. Mix chitosan with dilute acid solution. According to the weight ratio, chitosan accounts for 5 parts in every 100 parts, and the rest is the parts of dilute acid solution. After mixing, chitosan dilute acid solution is formed. Dilute chitosan acid The solution is mixed with the powdered seaweed plant in step A and then extruded under pressure. In proportion by weight, the chitosan dilute acid solution accounts for 95.0 parts per 100 parts, and the rest are the parts of the seaweed plant. The dilute acid solution is the concentrati...

Embodiment 3

[0042] Embodiment three, the processing technology of seaweed biosorbent material of the present embodiment comprises the following steps:

[0043] A, soaking the seaweed plants with a concentration of 5% hydrochloric acid solution, and processing the seaweed plants after hydrochloric acid treatment into powder; by weight ratio, the number of parts of the hydrochloric acid solution is 10 times the number of seaweed plants;

[0044] B. Mix chitosan with dilute acid solution. According to the weight ratio, chitosan accounts for 3 parts in every 100 parts, and the rest is the parts of dilute acid solution. After mixing, chitosan dilute acid solution is formed. Dilute chitosan acid The solution is mixed with the powdered seaweed plant in step A and then extruded under pressure. In proportion by weight, the chitosan dilute acid solution accounts for 98 parts per 100 parts, and the rest are the parts of the seaweed plant. The dilute acid solution is the concentration 2% aqueous solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com