Nano-particle compound and preparation method thereof

A nanoparticle and inorganic nanoparticle technology, which is applied in the field of nanoparticle composites and its preparation, can solve the problems of loss and limitation of the application of metal nanoparticles, and achieve good weather resistance, simple operation steps, and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

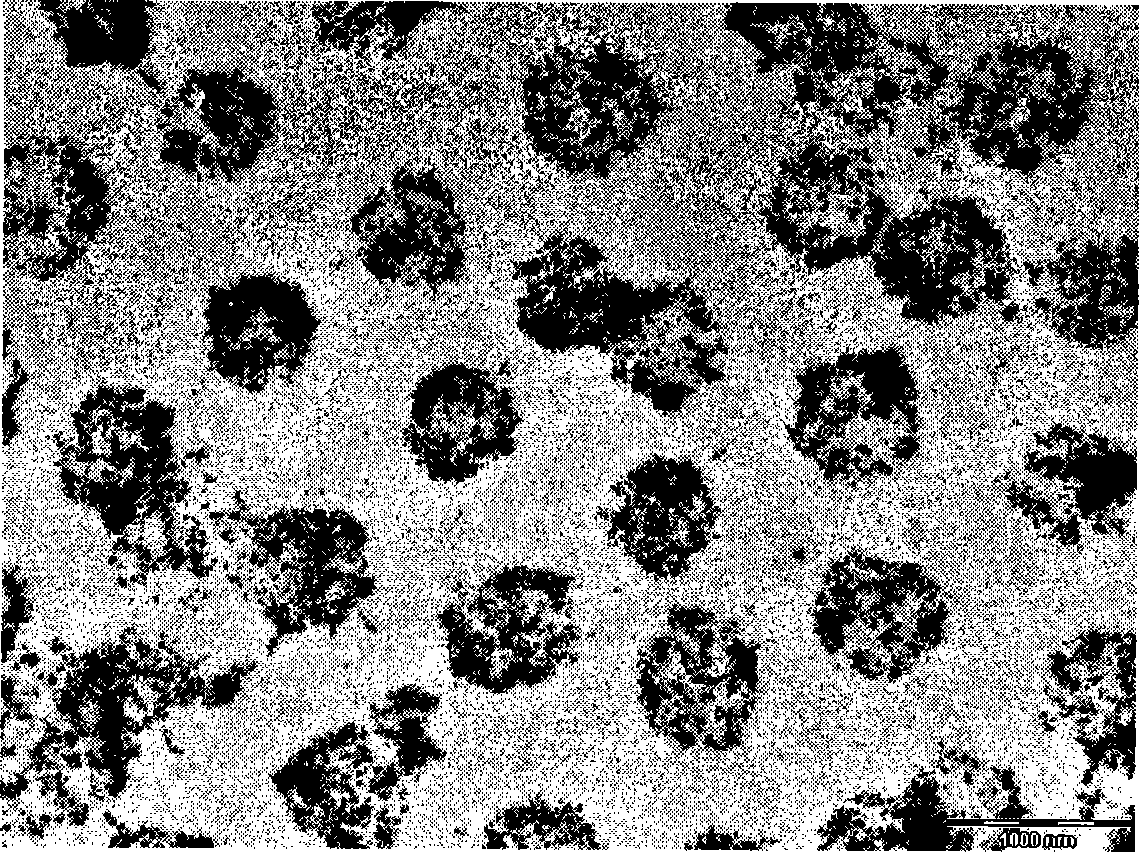

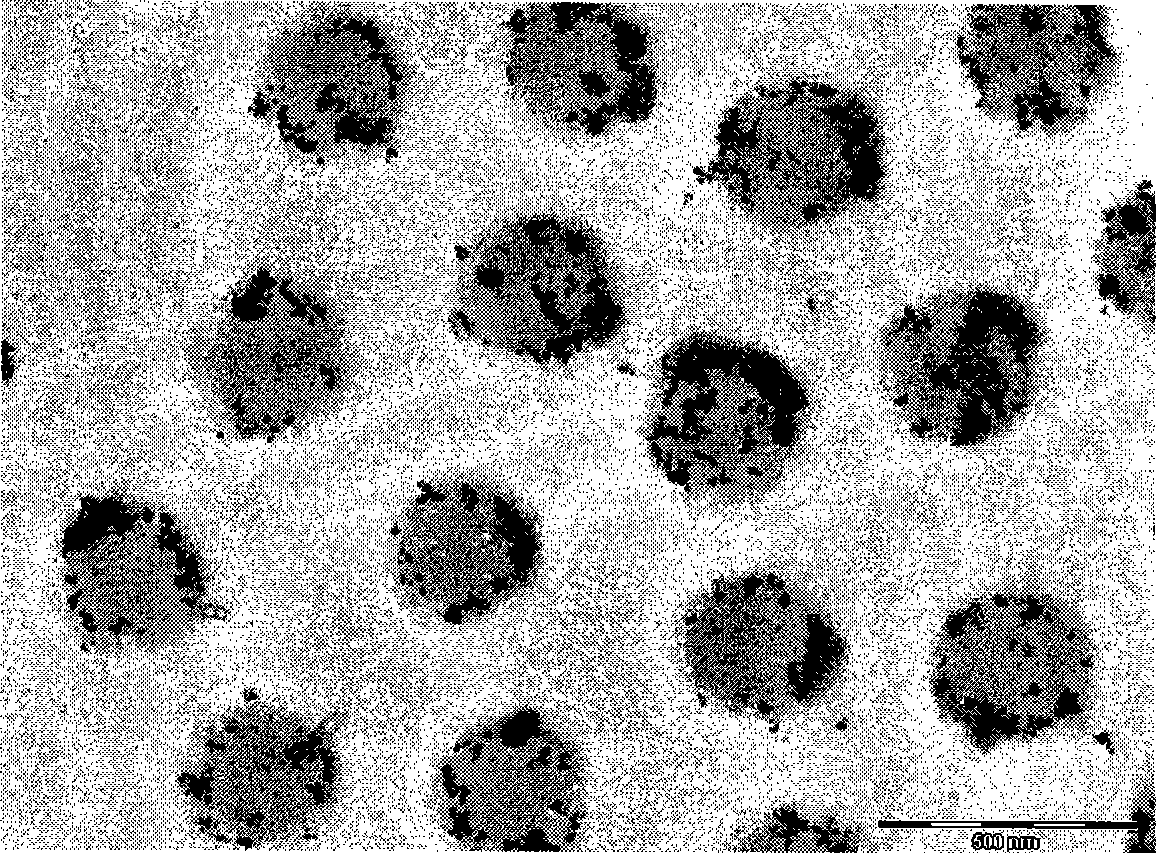

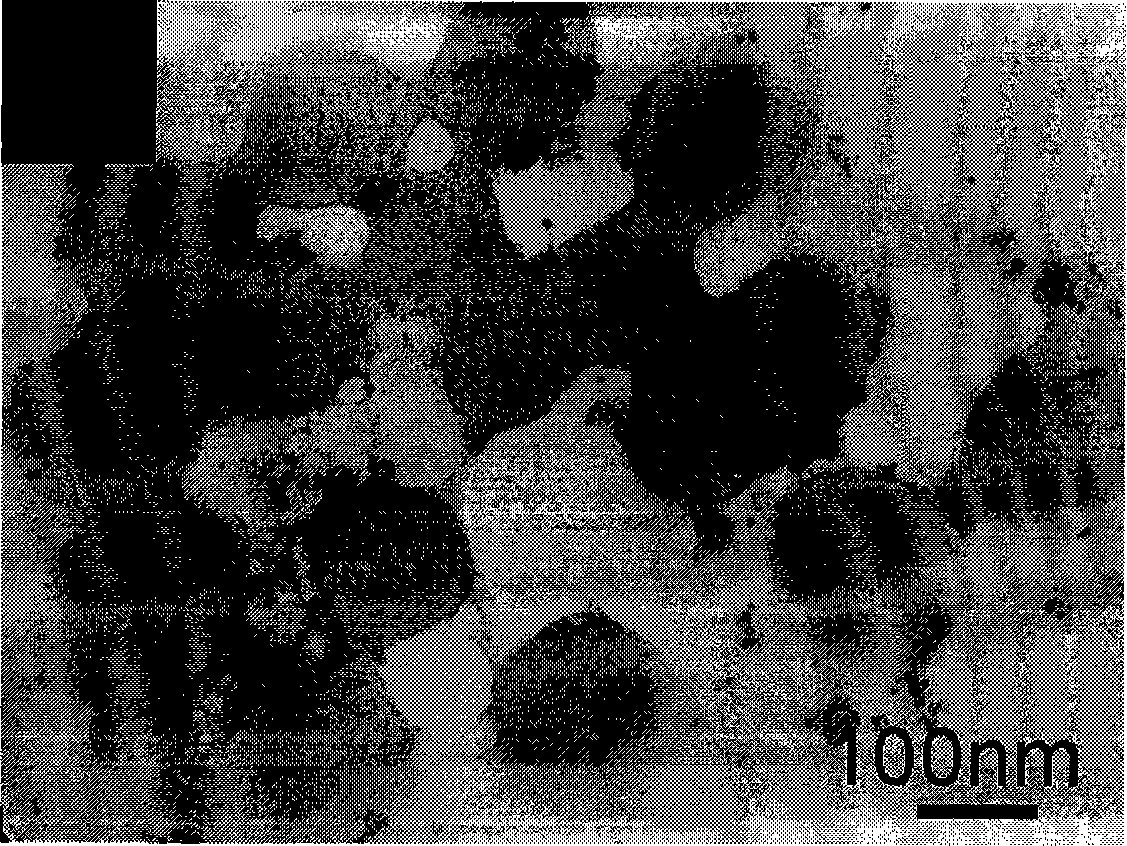

Image

Examples

Embodiment 1

[0025] 1) Preparation of isopropylacrylamide and acrylic acid copolymer hydrogel microspheres with a crosslink density of 4.5wt.-%:

[0026] Add 20 milliliters of water, 0.176 grams of isopropylacrylamide, and 4.5wt.-% methylenebisisopropylacrylamide with a quality of isopropylacrylamide in a 100 milliliter three-necked bottle equipped with a stirrer and a thermometer. Amide, 10 μL (0.01 g) of acrylic acid, stirred and filled with nitrogen for 30 minutes of oxygen removal, heated to 70 ° C, dissolved 0.004 g of ammonium persulfate in 5 ml of water and added to the above solution, and reacted for 4 hours under the protection of nitrogen. The resulting solution was dialyzed in deionized water for two weeks, then centrifuged (10000 rpm), poured out the upper layer liquid, added water to dissolve and centrifuged, and repeated the above operation three times to obtain a cross-linking density of 4.5wt.-%. Acrylamide-acrylic acid copolymer hydrogel microspheres.

[0027] 2) Preparat...

Embodiment 2

[0032] 1) Preparation of isopropylacrylamide and acrylic acid copolymer hydrogel microspheres with a crosslink density of 10wt.-%:

[0033] Add 20 milliliters of water, 0.176 grams of isopropylacrylamide, and 10 wt.-% methylene bisisopropylacrylamide in a 100 milliliter three-necked bottle equipped with a stirrer and a thermometer , 10 μL (0.01 g) of acrylic acid, stirred and filled with nitrogen for 30 minutes of oxygen removal, heated to 70 ° C, dissolved 0.004 g of ammonium persulfate in 5 ml of water and added to the above solution, and reacted for 4 hours under nitrogen protection. Dialyze the resulting solution in deionized water for two weeks, then centrifuge (10000 rpm), pour out the upper layer liquid, add water to dissolve and centrifuge, and repeat the above operation three times to obtain isopropyl with a crosslinking density of 10wt.-%. Acrylamide and acrylic acid copolymer hydrogel microspheres.

[0034] 2) Preparation of ferric oxide nanoparticles:

[0035] Wi...

Embodiment 3

[0039] 1) Preparation of isopropylacrylamide and acrylic acid copolymer hydrogel microspheres with a crosslink density of 15wt.-%:

[0040] Add 20 milliliters of water, 0.176 grams of isopropylacrylamide, and the methylenebisisopropylacrylamide whose quality is 15wt.-% of the mass of isopropylacrylamide in a 100 milliliter three-necked bottle equipped with a stirrer and a thermometer , 10 μL (0.01 g) of acrylic acid, stirred and filled with nitrogen for 30 minutes of oxygen removal, heated to 70 ° C, dissolved 0.004 g of ammonium persulfate in 5 ml of water and added to the above solution, and reacted for 4 hours under nitrogen protection. The resulting solution was dialyzed in deionized water for two weeks, then centrifuged (10000 rpm), poured out the upper liquid, dissolved in water and centrifuged, and repeated the above operation three times to obtain a cross-linking density of 15wt.-%. Acrylamide and acrylic acid copolymer hydrogel microspheres.

[0041] 2) Preparation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com