Ferroboron chemical plating liquid as well as ferroboron coating material and preparation method thereof

A technology of iron-boron alloy and chemical plating solution, which is applied in the fields of chemical plating solution and its coating material, iron-boron alloy chemical plating solution and its iron-boron coating material, and can solve the problem of violent reaction of the plating solution, reduction of polarization resistance, magnetic Performance changes and other issues, to achieve the effect of smooth coating surface, lower operating temperature, and improved bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Now take the substrate as copper (Cu) as an example, and the non-limiting examples are described as follows:

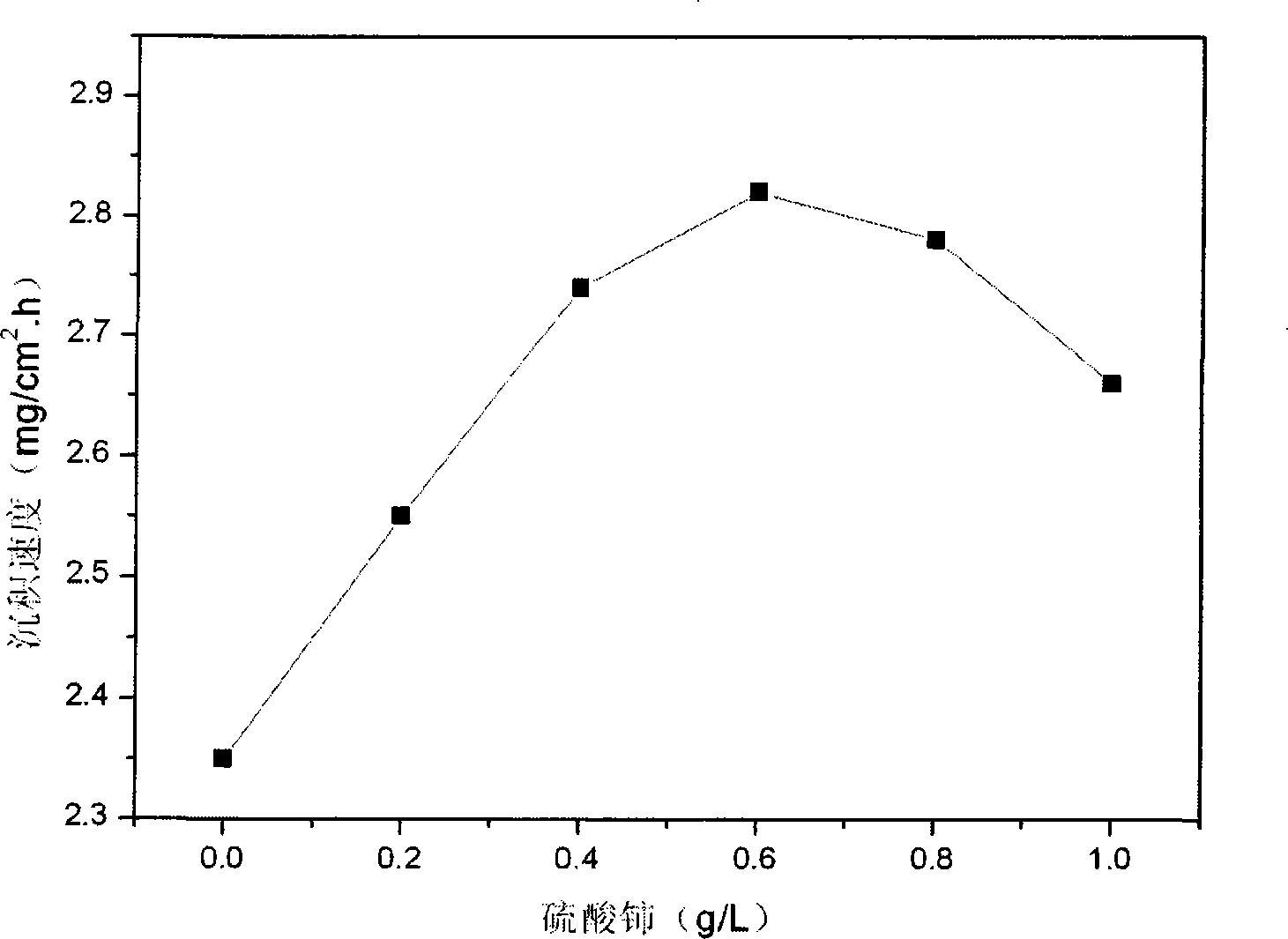

[0033] 1: Dissolve 18g of ferrous sulfate and 80g of potassium sodium tartrate in 400ml of distilled water evenly to prepare liquid A; dissolve 30g of sodium hydroxide in 400ml of distilled water in another container, stir evenly, add 4g of potassium borohydride to prepare Obtain B solution; mix A and B solutions evenly, then add 1g of cerium sulfate, add distilled water to make the volume of the solution reach 1000ml, stir evenly, heat to 45°C, and set aside. Put the pickled, sensitized, and activated copper sheet into the plating solution, contact the copper sheet with LG4 aluminum wire to initiate plating, and after 45 minutes of reaction, take out the copper sheet coated with Fe-B-RE alloy coating, wash with water, and dry , the deposition rate of Fe-B-RE coating measured by weighing method is 2.66mg / cm 2 h, the thickness of the coating is uniform, smooth,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com